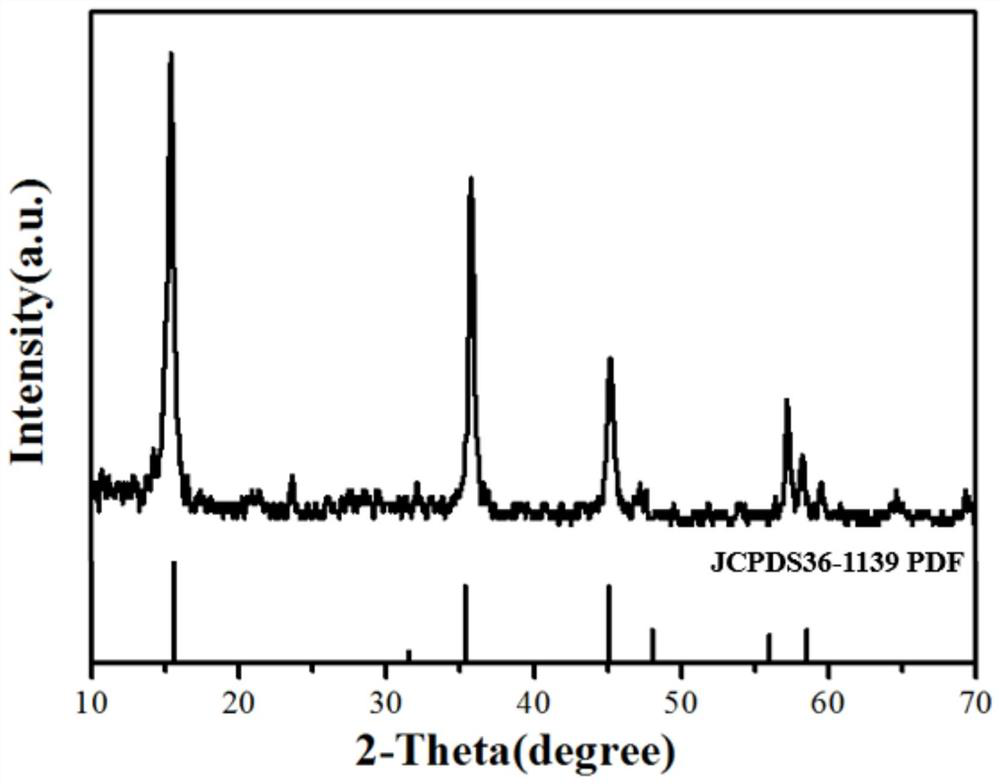

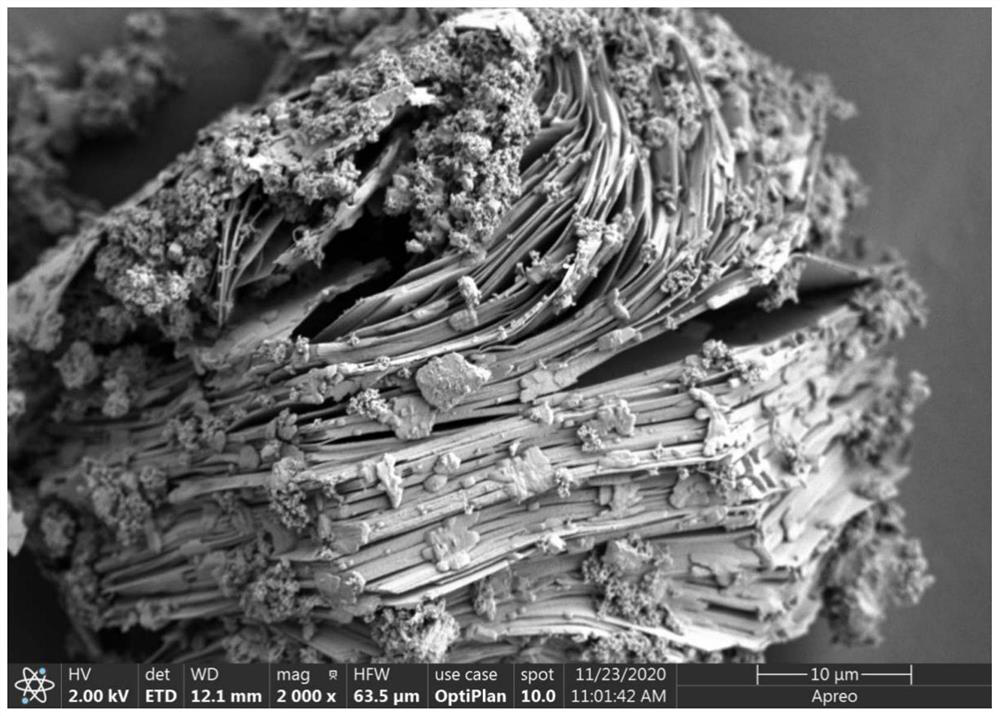

Cobalt-doped vanadium disulfide micron sheet and preparation method thereof

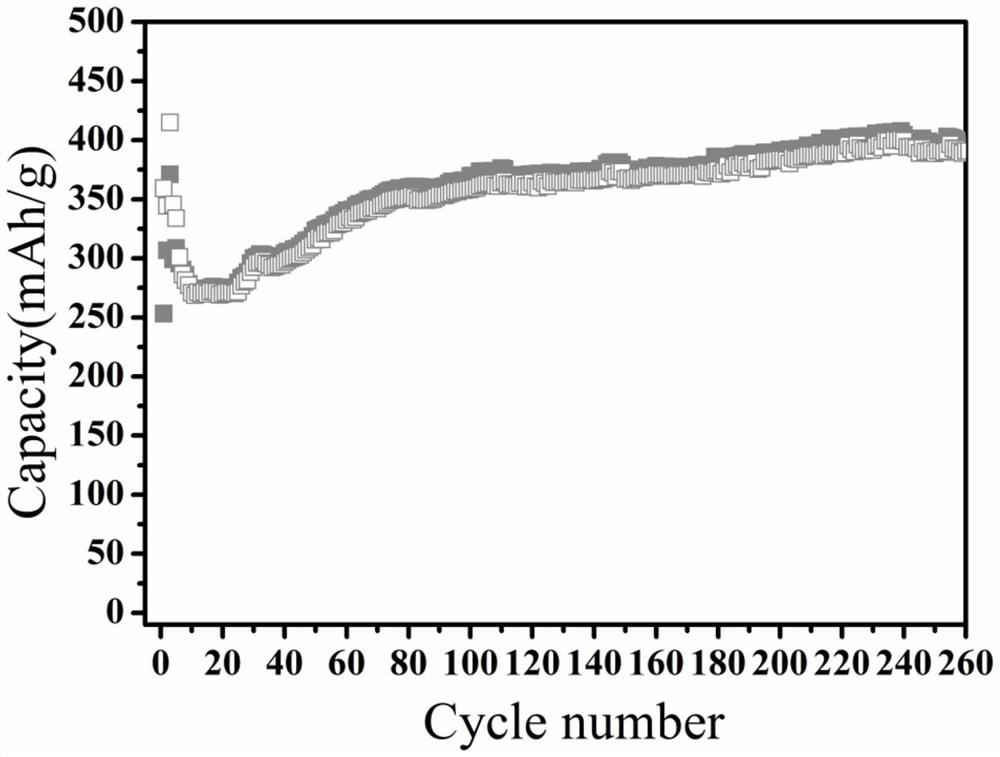

A technology of vanadium disulfide and micro-sheets, which is applied in the field of cobalt-doped vanadium disulfide micro-sheets and its preparation, which can solve problems such as hysteresis, poor cycle stability, rate performance, and pulverized charge transfer, and improve conductivity , improve electrochemical performance, promote the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a method for preparing cobalt-doped vanadium disulfide microsheets, which specifically comprises the following steps:

[0027] Step 1: 4mmol cobalt nitrate is dissolved in 100ml methanol, 16mmol bis-methylimidazole is dissolved in 100ml methanol, the methanol solution that is dissolved with bis-methylimidazole is slowly poured into the methanol solution that is dissolved with cobalt nitrate, using 500 The magnetic stirrer at ~700r / min was stirred at room temperature for 12h, and the solution was washed by methanol centrifugation three times, and the centrifuged samples were collected and dried in an oven at 60°C for 12h to obtain ZIF-67.

[0028] Step 2: Add 0.1g of ZIF-67 to 35ml of water and 7ml of ammonia water mixture, stir evenly, add a certain amount of sodium metavanadate to adjust the vanadium source concentration to 0.039mol / L, stir for 15min, add a certain amount of thio Acetamide, adjust the sulfur source concentration to 0.32mol / L, and...

Embodiment 2

[0031] The invention provides a method for preparing cobalt-doped vanadium disulfide microsheets, which specifically comprises the following steps:

[0032] Step 1: 4mmol cobalt nitrate is dissolved in 60ml methanol, 18mmol bis-methylimidazole is dissolved in 80ml methanol, the methanol solution that is dissolved with bis-methylimidazole is slowly poured into the methanol solution that is dissolved with cobalt nitrate, using 500 The magnetic stirrer at ~700r / min was stirred at room temperature for 16 hours, and the solution was washed by methanol centrifugation three times, and the centrifuged samples were collected and dried in an oven at 60°C for 12 hours to obtain ZIF-67.

[0033] Step 2: Add 0.1g of ZIF-67 to 35ml of water and 7ml of ammonia water mixture, stir evenly, add a certain amount of sodium metavanadate to adjust the concentration of vanadium source to 0.06mol / L, stir for 15min, add a certain amount of sulfur Substitute acetamide, adjust the sulfur source concentr...

Embodiment 3

[0039] The invention provides a method for preparing cobalt-doped vanadium disulfide microsheets, which specifically comprises the following steps:

[0040] Step 1: 4mmol cobalt nitrate is dissolved in 70ml methanol, 20mmol bis-methylimidazole is dissolved in 80ml methanol, the methanol solution that is dissolved with bis-methylimidazole is slowly poured into the methanol solution that is dissolved with cobalt nitrate, using 500 The magnetic stirrer at ~700r / min was stirred at room temperature for 18h, and the solution was washed by methanol centrifugation three times, and the centrifuged samples were collected and dried in an oven at 60°C for 12h to obtain ZIF-67.

[0041] Step 2: Add 0.1g of ZIF-67 to 40ml of water and 8ml of ammonia water mixture, stir evenly, add a certain amount of sodium metavanadate to adjust the concentration of vanadium source to 0.1mol / L, stir for 15min, add a certain amount of sulfur Substitute acetamide, adjust the sulfur source concentration to 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com