A kind of recycling method of reverse micellar dyeing system

A technology of dyeing system and reverse micelles, which is applied in the field of chemical industry and dyeing, can solve the problems of time-consuming, laborious and difficult to control, and achieve the effect of simple and easy preparation process, good adaptability to use, and environmentally friendly recycling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

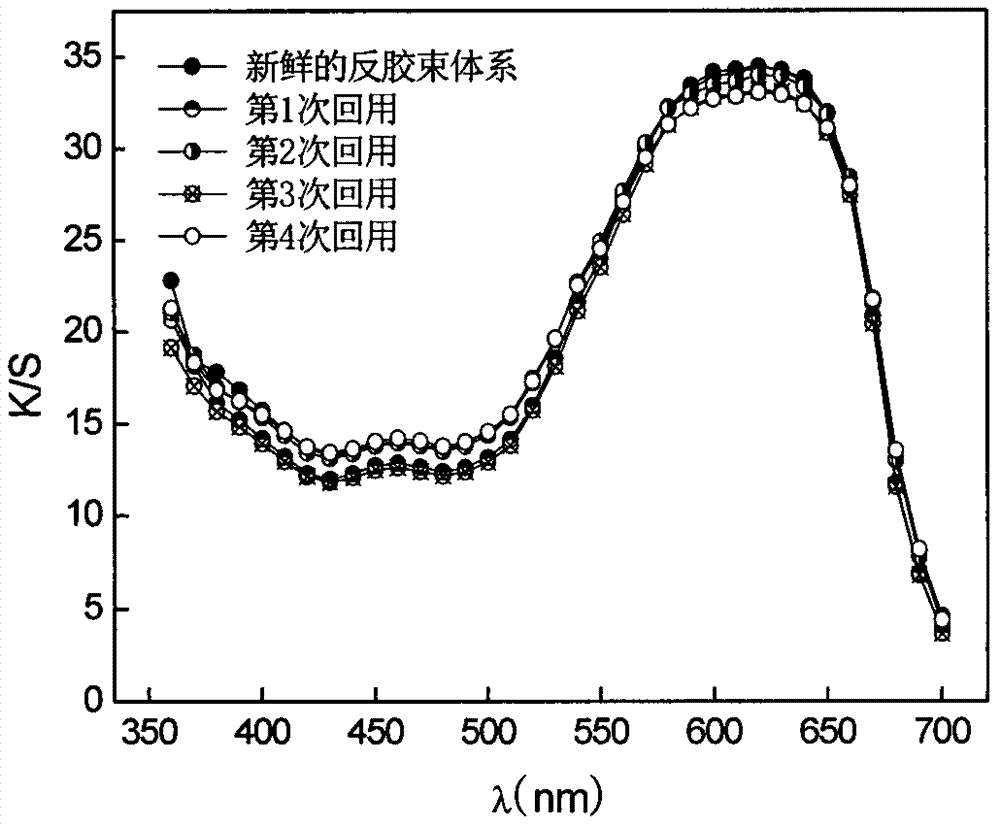

Embodiment 1

[0015] 1. Preparation of the reverse micellar system: First, 6.5 grams of nonionic surfactant TX-100, 8.5 grams of n-octanol and 25 grams of isooctane were placed in a beaker, and then 2.0 milliliters of them were injected with a concentration of 5.0 grams per liter using a micro-syringe. Acid Black 10B dye aqueous solution was injected therein, and stirred at room temperature for about 10 minutes, and then ultrasonicated for 5 minutes to obtain about 50 ml of reverse micellar dyeing system.

[0016] 2. Wool dyeing using fresh reverse micelles: 2.0 grams of pretreated wool yarns are placed in 100 ml reverse micelles dyeing system, and the wool yarns are dyed at a temperature of 60° C. and pH=2 and stirring conditions, After 2 hours, the woolen yarn was taken out and washed twice for 10 minutes at room temperature using a dye-free reverse micellar system, and finally the dyed woolen yarn was dried to obtain a fresh reversed micellar dyed sample;

[0017] 3. Pretreatment of wast...

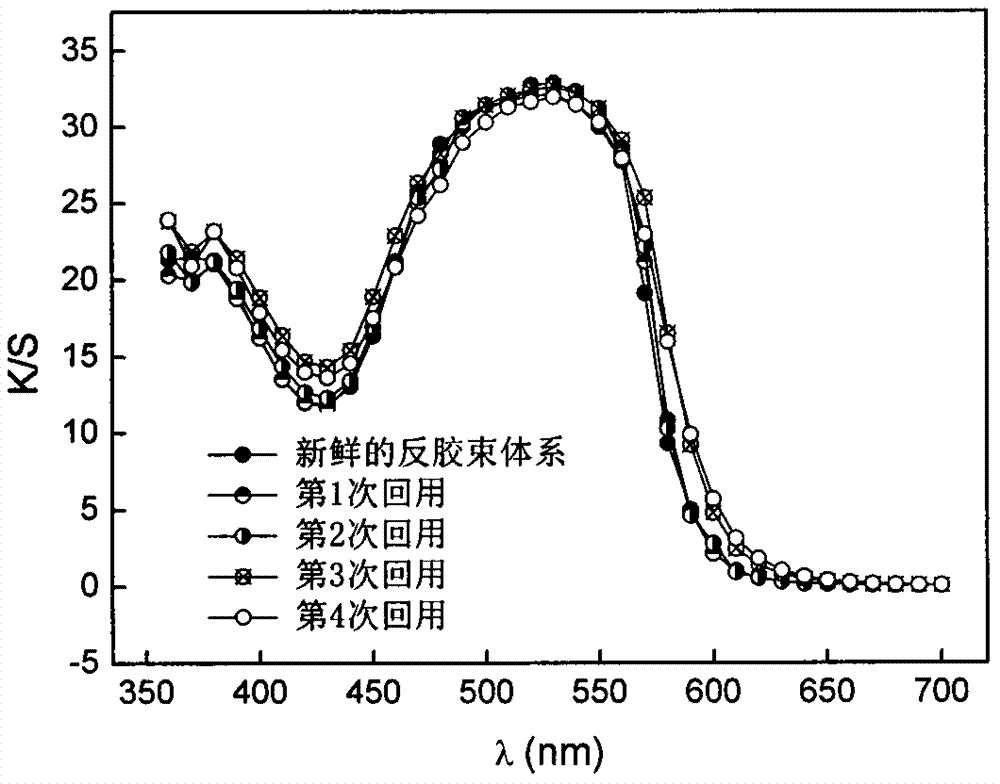

Embodiment 2

[0022] 1. described dyestuff is acid scarlet G, and all the other are identical with the 1-step process among the embodiment 1.

[0023] 2. The process is the same as the 2-step process in Example 1.

[0024] 3. The process is the same as the 3-step process in Example 1.

[0025] 4. The process is the same as the 4-step process in Example 1.

[0026] 5. The process is the same as the 5-step process in Example 1.

[0027] 6. described dyestuff is acid scarlet G, and all the other are with the 6 steps process among the embodiment 1.

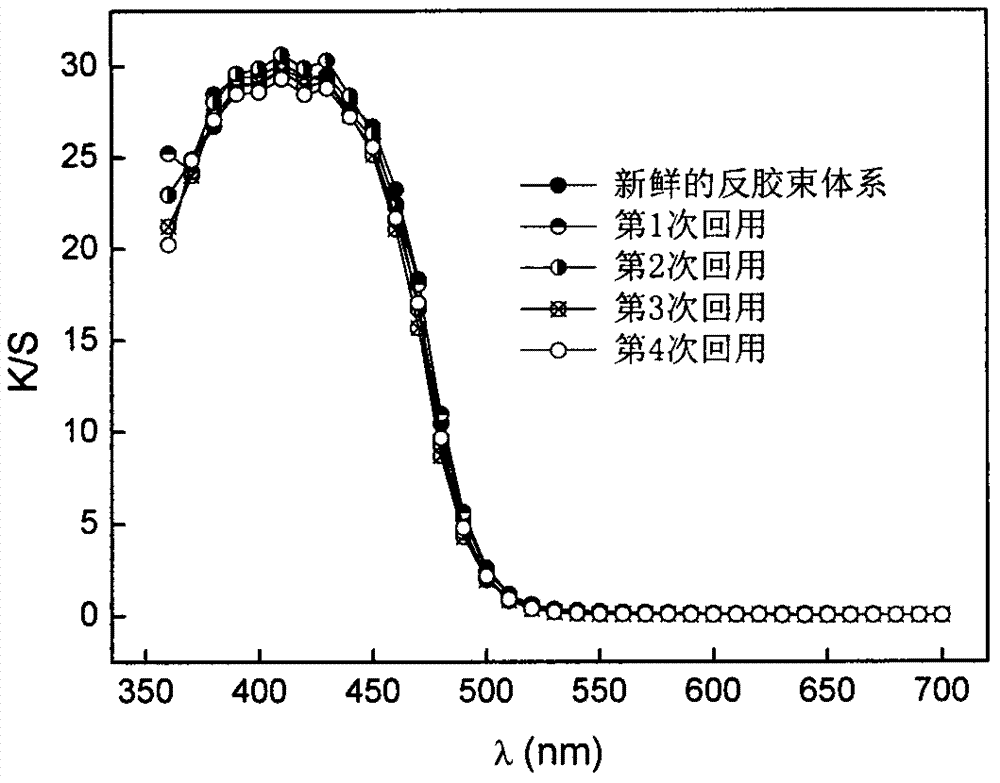

Embodiment 3

[0029] 1. The dyestuff is Acid Bright Yellow 2G, and the technique is the same as the 1-step technique in Example 1.

[0030] 2. The process is the same as the 2-step process in Example 1.

[0031] 3. The process is the same as the 3-step process in Example 1.

[0032] 4. The process is the same as the 4-step process in Example 1.

[0033] 5. The process is the same as the 5-step process in Example 1.

[0034] 6. described dyestuff is acid scarlet G, and all the other are with the 6 steps process among the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com