Composite positive electrode material with spring-shaped lamellar structure as well as preparation method and application of composite positive electrode material

A technology of composite cathode material and lamellar structure, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of low Coulombic efficiency, low discharge voltage, short cycle life, etc., and achieve shortened diffusion distance, strong structural rigidity, The effect of promoting penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

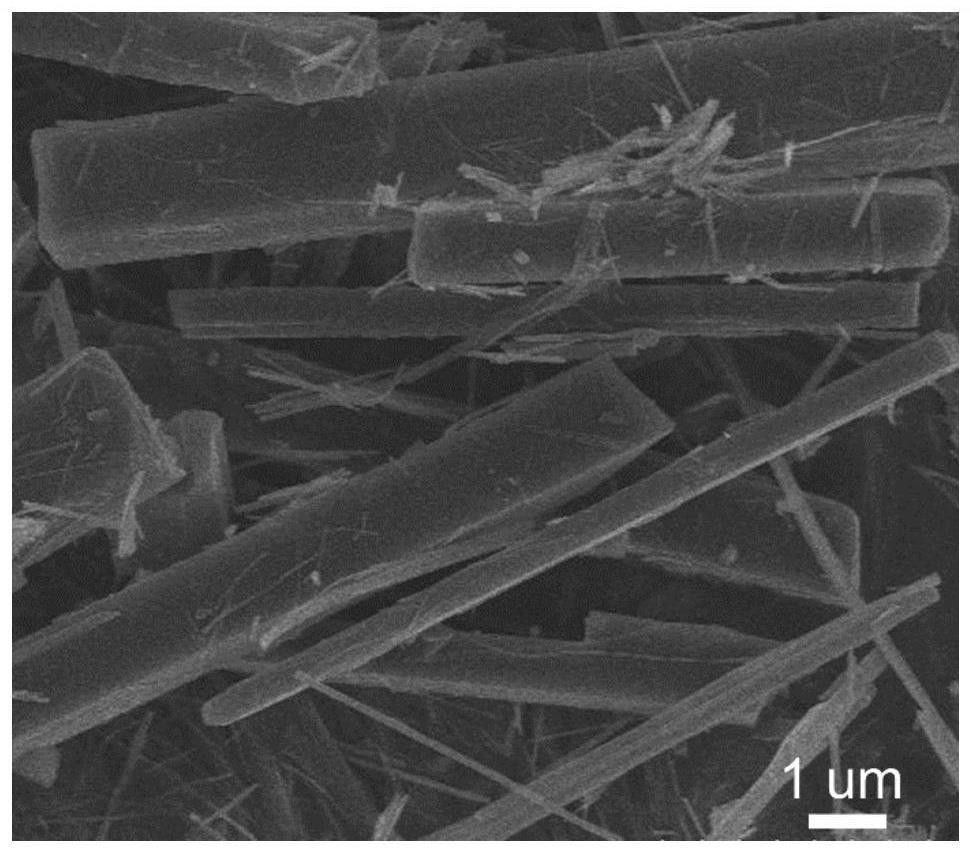

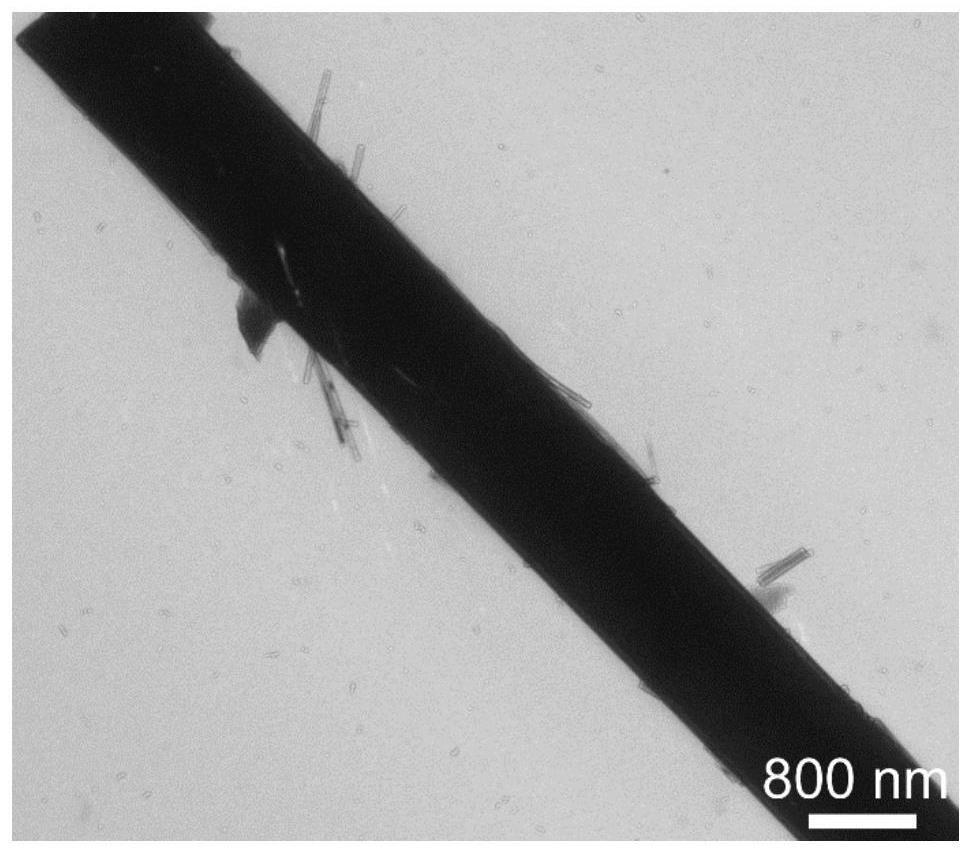

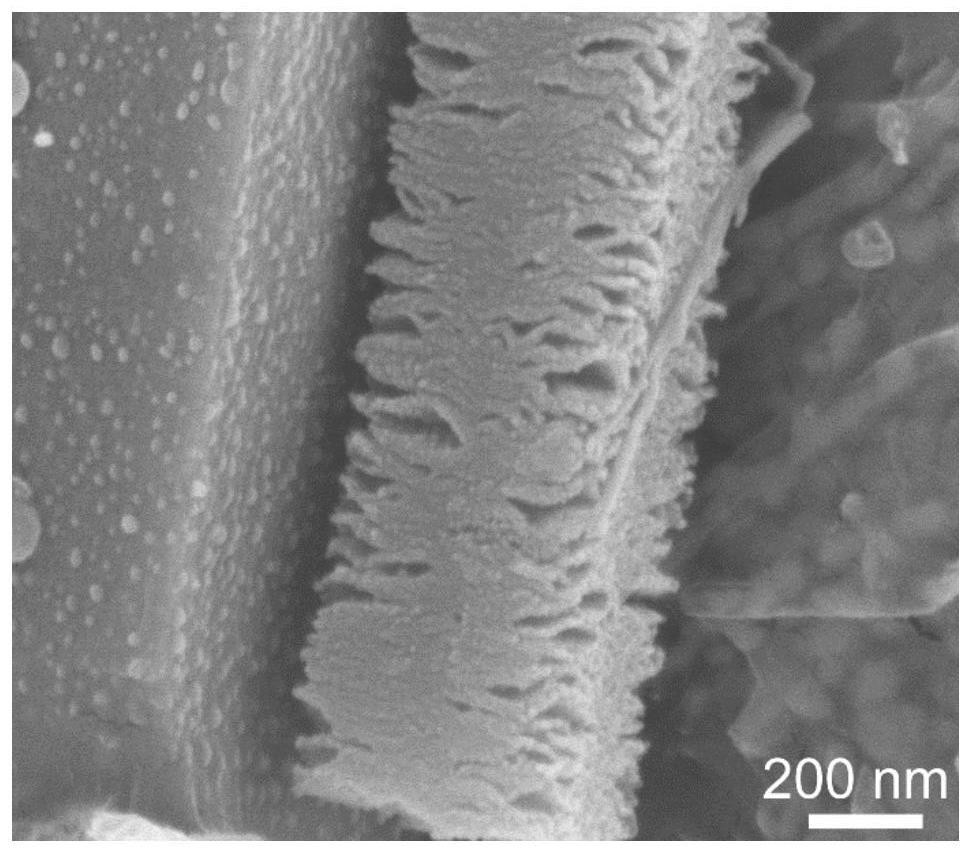

[0062] This embodiment provides a composite positive electrode material with a spring-like sheet structure, and the composite positive electrode material includes a carbon sheet and vanadium trioxide nanoparticles dispersed on the surface of the carbon sheet. The single-layer thickness of the composite positive electrode material is 35nm, and the single-layer width is 500nm.

[0063] The preparation method of the composite cathode material is as follows:

[0064] Vanadium dioxide (0.1866g) and 1,4-naphthalene dicarboxylic acid (0.3243g) with a molar ratio of 1.5:1 were stirred in 30mL of deionized water at a stirring rate of 700rpm for 4h. Precursor material was obtained after thermal reaction for 22 hours, washed by centrifugation with deionized water for 5 times, and then washed with ethanol twice for 5 minutes, and then dried at 60°C for 10 hours. Calcining at 750° C. for 5 hours in an argon atmosphere at a heating rate, and cooling to room temperature to obtain the compos...

Embodiment 2

[0066] This embodiment provides a composite positive electrode material with a spring-like sheet structure, and the composite positive electrode material includes a carbon sheet and vanadium trioxide nanoparticles dispersed on the surface of the carbon sheet. The single-layer thickness of the composite positive electrode material is 20nm, and the single-layer width is 200nm.

[0067] The preparation method of the composite cathode material is as follows:

[0068] Vanadium dioxide (0.1244g) and 1,4-naphthalene dicarboxylic acid (0.3243g) with a molar ratio of 1:1 were stirred in 30mL of deionized water at a stirring rate of 600rpm for 6h. Precursor material was obtained after thermal reaction for 24 hours, centrifuged and washed with deionized water for 4 times, and then washed with ethanol once for 1 minute, and then dried at 40°C for 12 hours. Calcining at 700° C. for 6 hours in an argon atmosphere at a heating rate, and cooling to room temperature to obtain the composite po...

Embodiment 3

[0070] This embodiment provides a composite positive electrode material with a spring-like sheet structure, and the composite positive electrode material includes a carbon sheet and vanadium trioxide nanoparticles dispersed on the surface of the carbon sheet. The thickness of a single layer of the composite positive electrode material is 50 nm, and the width of a single layer is 800 nm.

[0071] The preparation method of the composite cathode material is as follows:

[0072] Vanadium dioxide (0.2488g) and 1,4-naphthalene dicarboxylic acid (0.3243g) with a molar ratio of 2:1 were stirred in 30mL of deionized water at a stirring rate of 800rpm for 2h. Precursor material was obtained after thermal reaction for 20 hours, washed by centrifugation with deionized water for 6 times, and then washed with ethanol twice for 5 minutes, and then dried at 80°C for 8 hours. Calcining at 800° C. for 4 hours in an argon atmosphere at a heating rate, and cooling to room temperature to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com