Electrolyte for metal battery and metal battery

A metal battery, lithium metal battery technology, applied in the direction of secondary batteries, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor battery cycle stability, high chemical activity of lithium, limited content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of lithium ion battery electrolyte

[0027] It is composed of organic solvent, lithium salt and additives. The organic solvent is composed of ethylene carbonate and diethyl carbonate, and the volume ratio of ethylene carbonate and diethyl carbonate is 1:1. The lithium salt is lithium hexafluorophosphate, and the lithium salt is in the electrolyte The molar concentration in the electrolyte is 1mol / L, the electrolyte additive is stannous isooctanoate, and the mass fraction in the electrolyte is 1wt.%.

Embodiment 2

[0029] A kind of lithium ion battery electrolyte

[0030] It is composed of organic solvent, lithium salt and additives. The organic solvent is composed of ethylene carbonate and diethyl carbonate, and the volume ratio of ethylene carbonate and diethyl carbonate is 1:1. The lithium salt is lithium hexafluorophosphate, and the lithium salt is in the electrolyte The molar concentration in the electrolyte is 1mol / L, the electrolyte additive is stannous isooctanoate, and the mass fraction in the electrolyte is 2wt.%.

Embodiment 3

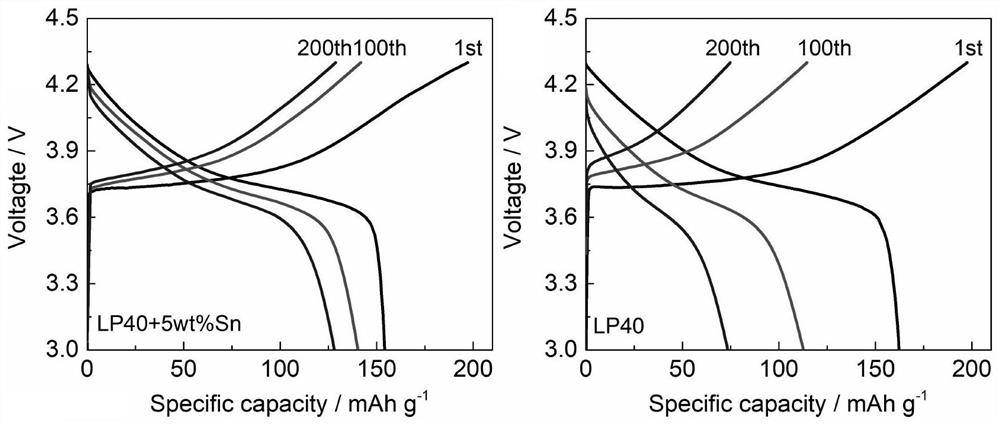

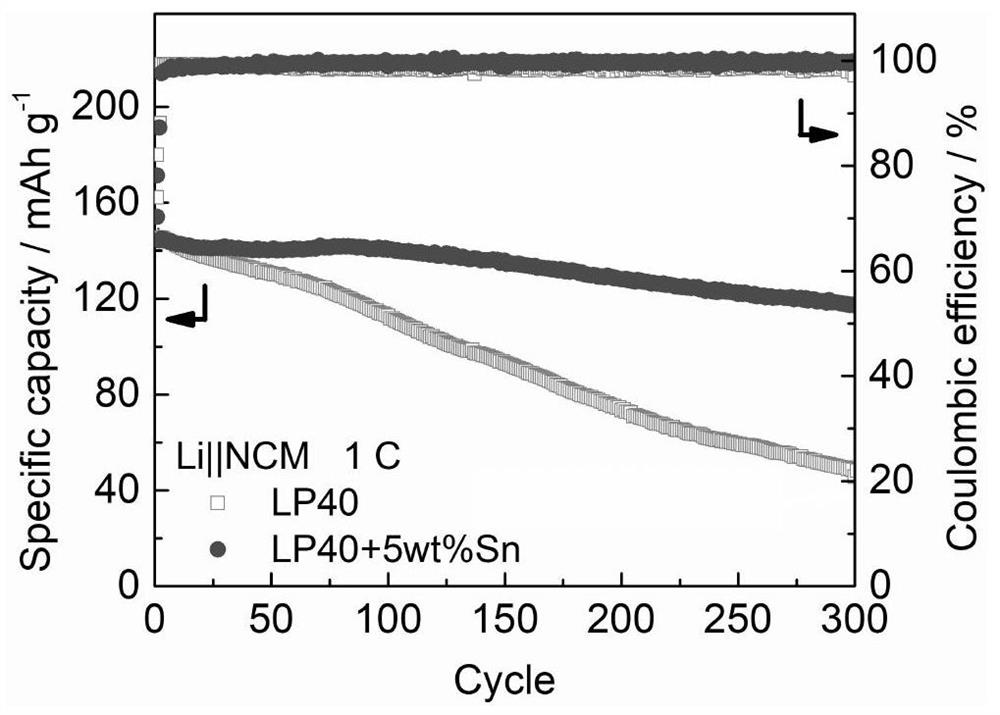

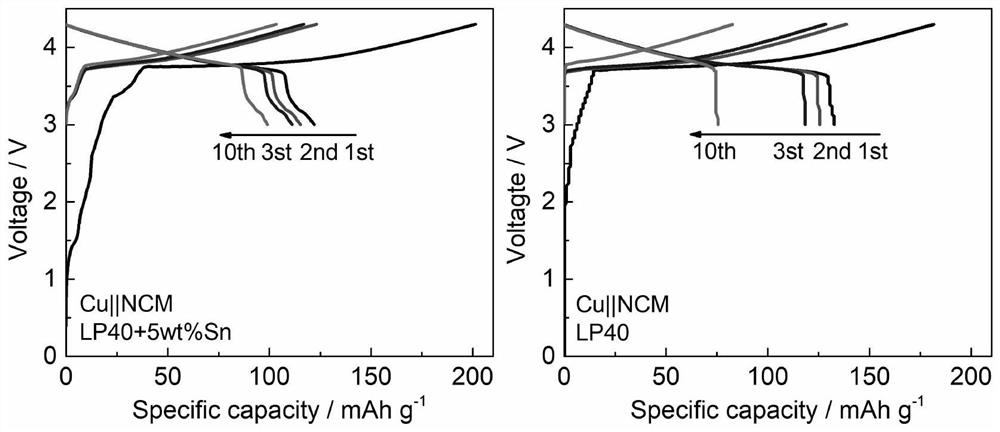

[0032] A kind of lithium ion battery electrolyte

[0033] It is composed of organic solvent, lithium salt and additives. The organic solvent is composed of ethylene carbonate and diethyl carbonate, and the volume ratio of ethylene carbonate and diethyl carbonate is 1:1. The lithium salt is lithium hexafluorophosphate, and the lithium salt is in the electrolyte The molar concentration in the electrolyte is 1mol / L, the electrolyte additive is stannous isooctanoate, and the mass fraction in the electrolyte is 5wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com