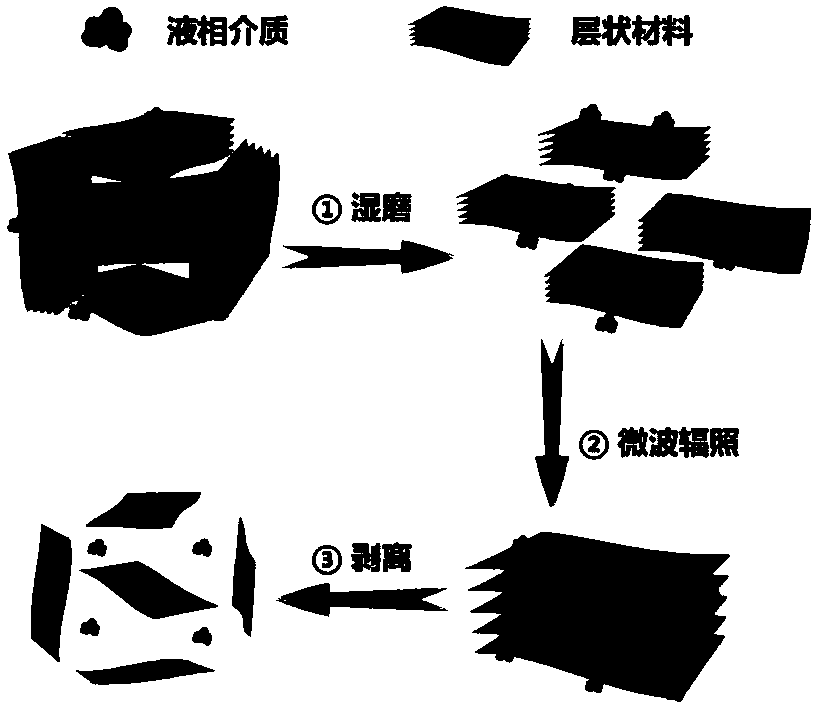

Method for preparing two-dimensional nanosheets by microwave-assisted liquid phase stripping of layered material

A layered material, liquid phase exfoliation technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of nanosheet size reduction, high operation risk, and long time consumption, etc., to achieve The effect of small peeling size reduction, high chemical stability, and high peeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

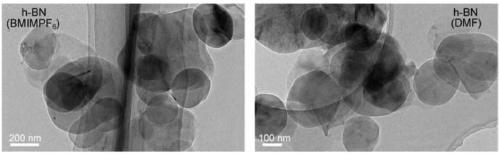

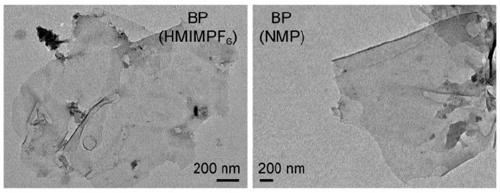

[0064] Preparation of h-BN nanosheets

[0065] Mix 10 mg of h-BN precursor powder with 0.3 mL of BMIMPF 6 Mix in an agate mortar, wet grind for 3min; then add 2.7mL of BMIMPF 6 Wash and transfer the wet grinding mixture to a soluble polytetrafluoroethylene (PFA) lined tube, and then place it in a microwave reaction tube. The final mixture volume is 3 mL; add matching A magnetic stirrer was placed into a microwave reaction device (Discover SP ring-focused single-mode microwave synthesis system produced by CEM, USA), the microwave parameters were set to 30W / 30min, high-speed stirring, and the upper temperature limit was set to 170°C. After microwave irradiation, dilute the mixture to 6mL with dimethyl sulfoxide (DMSO), filter with glass sand core filter, adopt polytetrafluoroethylene (PTFE) filter membrane, and use 50mL of absolute ethanol (this implementation Example and the ethanol in the following examples are absolute ethanol) to rinse the microwave reaction tube and the f...

Embodiment 2

[0067] Preparation of h-BN nanosheets

[0068] Mix 10 mg of h-BN precursor powder and 0.3 mL of DMF in an agate mortar, and wet-mill for 3 min; then wash the wet-milled mixture with 2.7 mL of DMF and transfer it to a microwave reaction tube, and the final volume of the mixture is 3 mL; Add a matching magnetic stirrer into the microwave reaction tube, and place it into a microwave reaction device (Discover SP ring-focused single-mode microwave synthesis system produced by CEM, USA). The microwave parameters are set to 120W / 45min, the Power Max function is turned on, and the high-speed Stir and set the upper temperature limit to 95 °C. After microwave irradiation, dilute the mixture to 6mL with dimethyl sulfoxide (DMSO), filter with a glass sand core filter, and use a polytetrafluoroethylene (PTFE) filter membrane, rinse the microwave reaction tube with 50mL of ethanol during the suction filtration , filter cup; soak the obtained filter membrane in a beaker filled with 10mL eth...

Embodiment 3

[0073] Prepare g-C 3 N 4 Nanosheets

[0074] 10mg of g-C 3 N 4 Precursor powder with 0.3 mL of HMIMBF 4 Mix in an agate mortar, wet grind for 3min; then add 2.7mL of HMIMBF 4 Wash and transfer the wet grinding mixture to a soluble polytetrafluoroethylene (PFA) lined tube, and then place it in a microwave reaction tube. The final volume of the mixture is 3 mL; add matching A magnetic stirrer was placed into a microwave reaction device (Discover SP ring-focused single-mode microwave synthesis system produced by CEM, USA), the microwave parameters were set to 30W / 30min, high-speed stirring, and the upper temperature limit was set to 170°C. After microwave irradiation, dilute the mixture to 6mL with dimethyl sulfoxide (DMSO), filter with a glass sand core filter, and use a polytetrafluoroethylene (PTFE) filter membrane, rinse the microwave reaction tube with 50mL of ethanol during the suction filtration , filter cup; soak the obtained filter membrane in a beaker filled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com