Two-dimensional nanosheet and preparation method and usage thereof

A two-dimensional nano, alkyl lithium technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0086] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0087] Instruments and Equipment

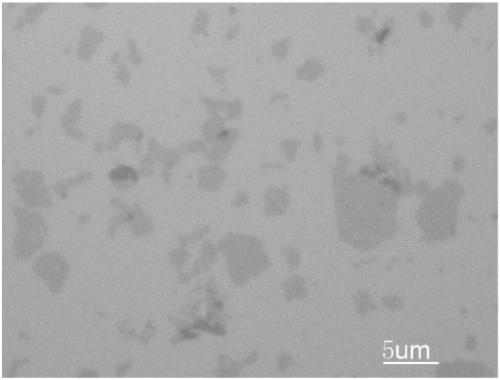

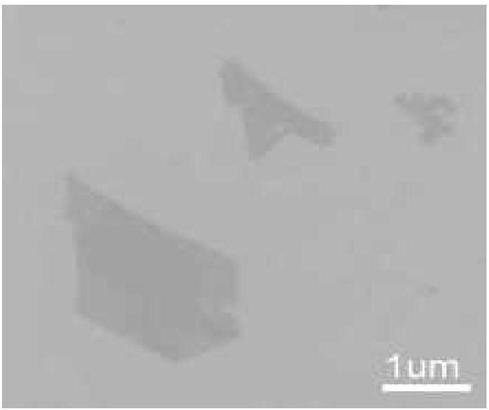

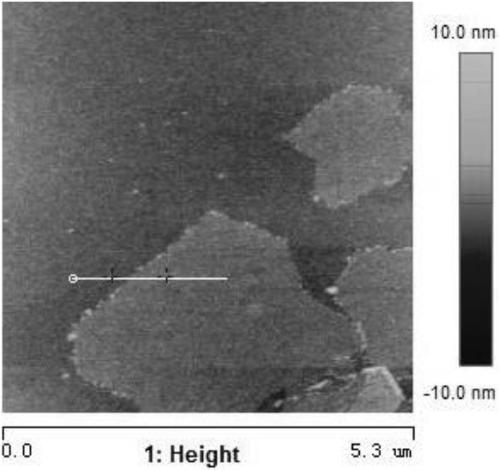

[0088] The optical microscope photos are tested with an optical microscope manufactured by Nikon. The test method is to directly observe the silicon wafer sample containing nanosheets on the stage to characterize ...

Embodiment 1

[0097] Example 1MoS 2 Preparation of dispersion

[0098] 1) Preparation of n-butyllithium intercalated MoS 2

[0099] At room temperature, add 0.5g MoS to a 25ml autoclave 2powder, then add 5ml of n-butyllithium n-hexane solution in an inert atmosphere, and stir at room temperature for 20 minutes; then place it in an oven and heat at 100°C for 24 hours, and after 24 hours of reaction, take out the autoclave and cool it to room temperature; The mixture was poured into 50ml of n-hexane, vacuum filtered, the filter residue was washed with n-hexane solution to remove residual n-butyllithium, and the filter residue was blown to dryness with argon to obtain a large amount of black solid.

[0100] 2) MoS 2 Preparation of dispersion

[0101] 0.5g of synthesized intercalated MoS 2 Added to 100ml dimethyl sulfoxide solution. Put it in a 250ml beaker, sonicate at a lower power for 120 minutes, and get a black solution with a lot of precipitation, which is MoS 2 Dispersion liquid,...

Embodiment 2

[0126] Example 2TiS 2 Preparation of dispersion

[0127] The preparation method is basically the same as in Example 1, the difference is only that step 1) is

[0128] At room temperature, add 0.5g TiS to a 25ml autoclave 2 powder, then add 5ml n-butyllithium n-hexane solution in an inert atmosphere, and stir at room temperature for 20 minutes; pour the mixture into 50ml n-hexane, vacuum filter, and wash the filter residue with n-hexane solution to remove residual n-butyl Lithium, the filter residue was blown to dryness with argon to obtain a large amount of black solid.

[0129] Monolayer TiS can be obtained by the above method 2 The dispersion liquid has a size of more than ten microns and a thickness of 0.6-3 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com