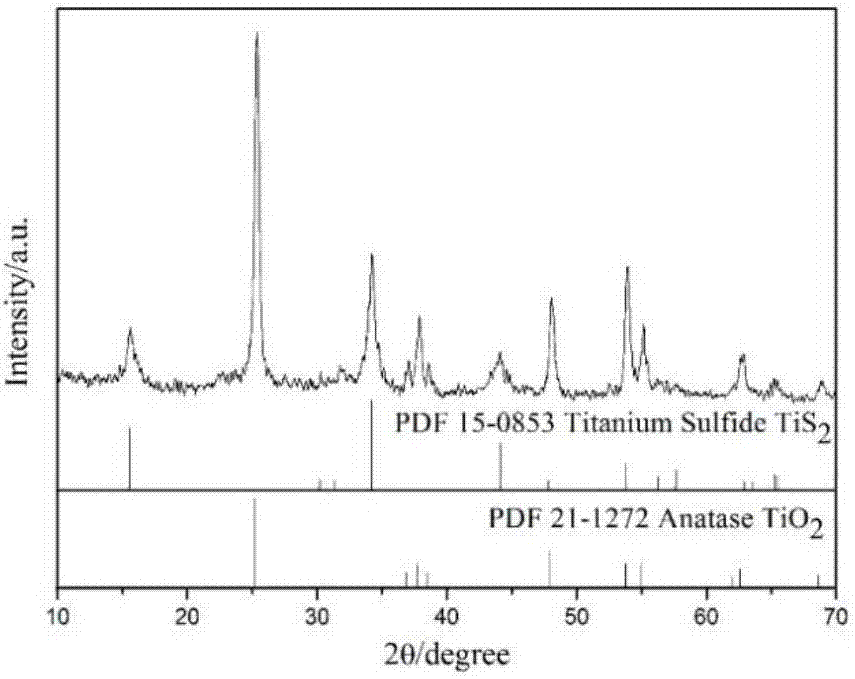

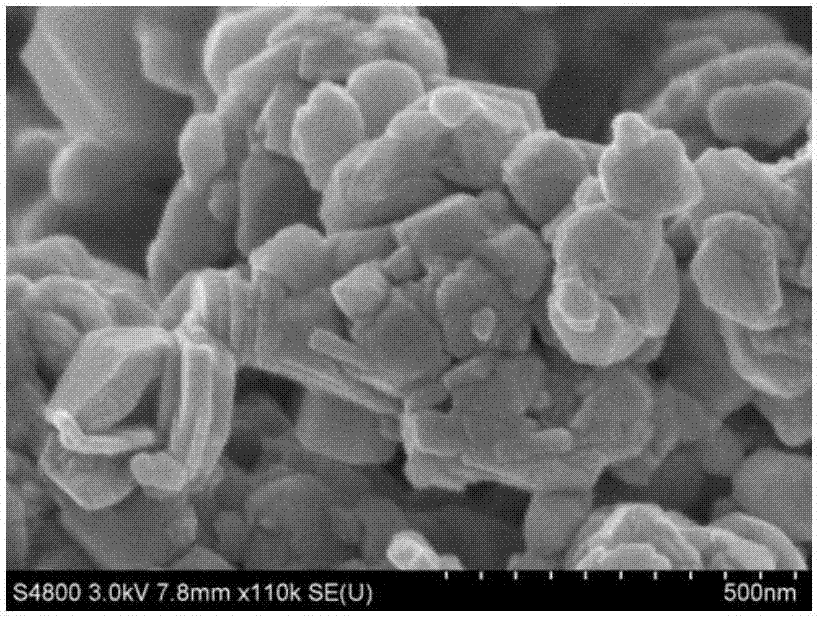

Method for synthesizing titanium dioxide/ titanium disulfide composite material by using one-step vulcanization method

A technology of titanium dioxide and composite materials, applied in the direction of titanium dioxide, titanium oxide/hydroxide, titanium sulfide, etc., can solve the problems of high experimental conditions, impure products, low yield, etc., and achieve high material purity and uniform shape , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Weigh 2ml of butyl titanate and add it dropwise to 8ml of ethanol solution under the action of magnetic stirring to form a homogeneous mixture A, then add 1ml of ethanol to 40ml of deionized water under the action of magnetic stirring to form a uniform mixed solution b.

[0044] 2) The mixed solution A is added dropwise into the mixed solution B under the action of stirring, and then ultrasonicated for 0.5 h to obtain a transparent solution C. In addition, 0.1 mol / L HCl was added to adjust the pH value to 6 to obtain solution D.

[0045] 3) The solution D is added into the polytetrafluoroethylene lining, the filling ratio is controlled at 40%, the reaction temperature is controlled at 160°C, and the reaction time is controlled at 12h.

[0046] 4) After the reaction is completed, centrifuge and wash 3 times with deionized water and ethanol respectively. After vacuum drying at 80°C for 6 h, TiO was obtained by grinding 2 Precursor.

[0047] 5) Weigh a certain amoun...

Embodiment 2

[0052] 1) Weigh 4ml of butyl titanate and add it dropwise to 9ml of ethanol solution under the action of magnetic stirring to form a homogeneous mixture A, then add 2ml of ethanol to 40ml of deionized water under the action of magnetic stirring to form a uniform mixed solution b.

[0053] 2) The mixed solution A is added dropwise into the mixed solution B under the action of stirring, and then ultrasonicated for 1.5 hours to obtain a transparent solution C. In addition, 0.1 mol / L HCl was added to adjust the pH value to 6 to obtain solution D.

[0054] 3) The solution D is added to the polytetrafluoroethylene lining, the filling ratio is controlled at 50%, the reaction temperature is controlled at 180°C, and the reaction time is controlled at 16h.

[0055] 4) After the reaction is completed, centrifuge and wash 5 times with deionized water and ethanol respectively. After vacuum drying at 80 °C for 8 h, TiO was obtained by grinding 2 Precursor.

[0056] 5) Weigh a certain am...

Embodiment 3

[0062] 1) Weigh 6ml of butyl titanate and add it dropwise to 10ml of ethanol solution under the action of magnetic stirring to form a homogeneous mixture A, then add 3ml of ethanol to 40ml of deionized water under the action of magnetic stirring to form a uniform mixed solution b.

[0063] 2) The mixed solution A is added dropwise into the mixed solution B under the action of stirring, and then the transparent solution C is obtained by ultrasonication for 2 hours. In addition, 0.1 mol / L HCl was added to adjust the pH value to 6 to obtain solution D.

[0064] 3) The solution D is added into the polytetrafluoroethylene lining, the filling ratio is controlled at 60%, the reaction temperature is controlled at 200° C., and the reaction time is controlled at 20 h.

[0065] 4) After the reaction is completed, centrifuge and wash 6 times with deionized water and ethanol respectively. After vacuum drying at 80°C for 10 h, TiO was obtained by grinding 2 Precursor.

[0066] 5) Weigh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com