Pseudo-boehmite, preparing method and aluminium oxide prepared from pseudo-boehmite

A technology of pseudo-boehmite and hydrated alumina, which is applied in the field of alumina, can solve the problems of catalyst hydrodesulfurization performance deviation, etc., and achieve the effect of excellent hydrodesulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to the preparation method of pseudo-boehmite provided by the present invention, although any one of the processes in the hydrolysis reaction or precipitation reaction and aging can be carried out in the presence of a grain growth regulator, the purpose of the present invention can be achieved, but preferably In this case, the hydrolysis reaction and aging process or the precipitation reaction and aging process are all carried out in the presence of a grain growth regulator, so that n of the obtained pseudo-boehmite can be preferably in the range of 1.2≤n≤2.2.

[0030] The present invention has no special limitation on the amount of the grain growth regulator, preferably the amount of the grain growth regulator in the hydrolysis reaction is 0.5-10% by weight of the weight of the organic aluminum-containing compound to be hydrolyzed, more preferably 1-8.5% by weight , more preferably 5-8.5% by weight; the amount of the grain growth regulator in the precipitation ...

Embodiment 1

[0056] This example is used to illustrate that the present invention provides pseudo-boehmite and its preparation method.

[0057] In a 2-liter reaction tank, add 600 milliliters of concentration and be 96 grams of alumina / liter, aluminum sulfate solution containing 3.6 grams of ribitol and ammonia solution of 8% by weight to carry out precipitation reaction in parallel, and the reaction temperature is 40 ℃ , the reaction time is 10 minutes, the flow rate of the ammonia solution is controlled so that the pH of the reaction system is 7, after the precipitation reaction is completed, an appropriate amount of ammonia water is added to the slurry to make the pH of the slurry 8.5, and the slurry is aged at 55°C for 60 minutes and then filtered. The filter cake was beaten and washed twice with deionized water, and dried at 120°C for 24 hours to obtain hydrated alumina P1, which was characterized by XRD and P1 had a pseudo-boehmite structure.

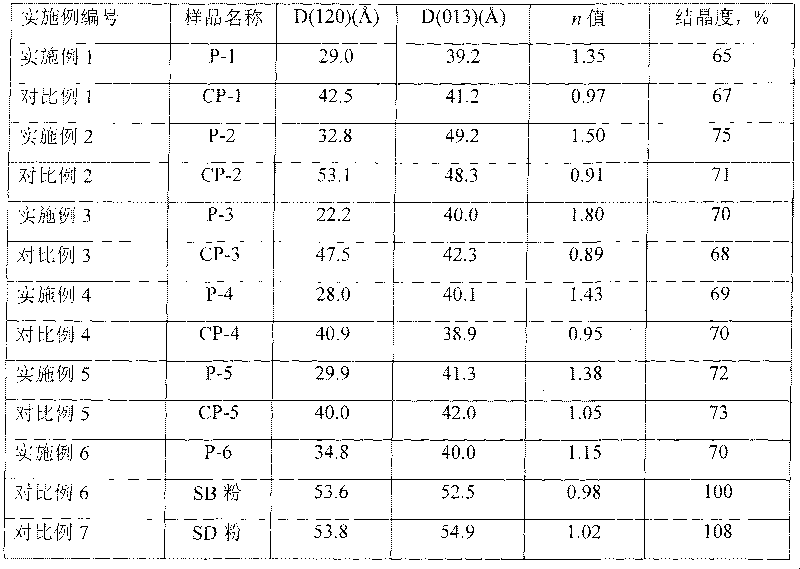

[0058] XRD was measured on a SIMENS D50...

Embodiment 2

[0062] This example is used to illustrate that the present invention provides pseudo-boehmite and its preparation method.

[0063] High-concentration NaAlO containing 210 grams of alumina / liter and a caustic coefficient of 1.62 2 solution with deionized water to prepare Al 2 o 3 Concentration is 5 liters of solution of 40 grams / liter, then adds 16.3 grams of sodium gluconate to obtain NaAlO containing sodium gluconate 2 solution, and then transferred to a gelling reactor with a total volume of 8L, the ratio of height to diameter of the reactor is 8, and the lower part is equipped with CO 2 gas distributor. Control the temperature of the solution at 25±5°C, and feed CO with a concentration of 90% by volume from the bottom of the reactor 2 The gas carries out the gelation reaction, the gelation temperature is controlled at 20-40°C, and the CO 2 The gas flow rate is 15±2 liters / minute, and the pH value at the end of the reaction reaches 8.0-8.5 within 4-6 minutes, that is, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com