A kind of preparation method of bulk hydrorefining catalyst

A catalyst and system technology, which is applied in the field of preparation of low-quality distillate oil deep hydrotreating catalysts, can solve the problems of high catalyst use cost, low utilization rate of active metals, poor dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

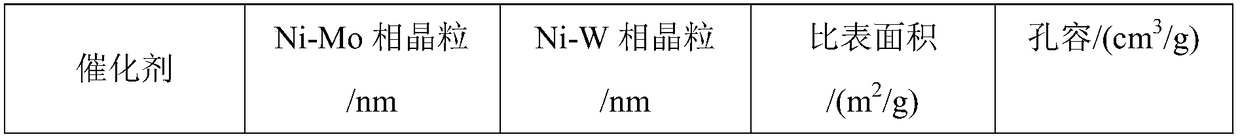

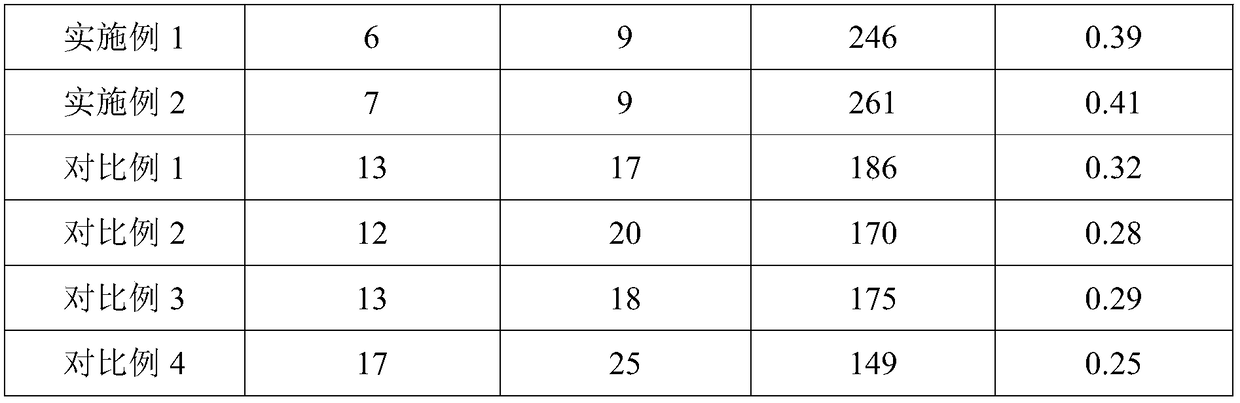

Embodiment 1

[0020] Mix 25g of basic nickel carbonate and 300ml of deionized water evenly and add it to a 1L high-pressure ultrasonic reactor, set the ultrasonic frequency to 60KHz, heat the mixture to 80°C, keep the temperature for 1 hour, reduce the ultrasonic frequency to 20KHz, and raise the system temperature to 120 ℃, add 26.5g of ammonium molybdate and 3g of polyvinylpyrrolidone, then add 10ml of ammonia water with a concentration of 25wt% dropwise into the system, keep the temperature for 2 hours, turn off the ultrasound, turn on the stirring at a speed of 300 rpm, and add 39.6g of partial tungsten Ammonium acid, then add citric acid until the pH of the system is 4.2, keep the temperature for 2 hours, turn off the heating, collect the slurry after the system drops to room temperature, spray dry the slurry, and control the inlet temperature and outlet temperature at about 200°C and 100°C respectively , The obtained dry powder was calcined in a muffle furnace at 330°C for 3h to obtain...

Embodiment 2

[0022] Mix 44.3g of nickel acetate and 300ml of deionized water evenly and add it to a 1L high-pressure ultrasonic reactor, set the ultrasonic frequency to 60KHz, heat the mixture to 80°C, keep the temperature for 1 hour, reduce the ultrasonic frequency to 20KHz, and raise the system temperature to 120°C , add 21.6g of molybdenum trioxide and 3g of polyvinylpyrrolidone, then add 10ml of ammonia water with a concentration of 25wt% dropwise into the system, keep the temperature for 2 hours, turn off the ultrasonic, turn on the stirring at a speed of 300 rpm, and add 39.6g of metatungstic acid Ammonium, then add citric acid until the pH of the system is 4.2, keep the temperature for 2 hours, turn off the heating, collect the slurry after the system drops to room temperature, and spray dry the slurry. The inlet temperature and outlet temperature are controlled at about 200°C and 100°C, The obtained dry powder was calcined at 330° C. for 3 hours in a muffle furnace to obtain the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com