Aluminum oxide-activated carbon composite carrier, preparation method and prepared catalyst

A technology of composite carrier and activated carbon, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc. High porosity, poor mechanical strength, etc., to achieve excellent hydrodesulfurization performance and optimize pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Preparation of alumina-activated carbon composite carrier

[0016] Weigh 4 grams of ball milled to less than 320 mesh (0.046mm) alumina (Al 2 o 3 ) powder, add 1 milliliter of 50% aqueous acetic acid solution, stir for 30 minutes to fully mix, then add 1 gram of active carbon (marked as AC) powder with equal particle size, and add 1.2 grams of sucrose as a binder, and continue to stir for 15 minutes Make the mixture even. Gained black viscous matter was left to stand in a closed plastic container for 24 hours, and then pressed into tablets. The obtained small cylindrical shape was dried at 110°C, then calcined at 600°C for 2 hours in a nitrogen atmosphere, and cooled to obtain an alumina-activated carbon composite carrier with a mass fraction of 20% activated carbon, marked as AAC.

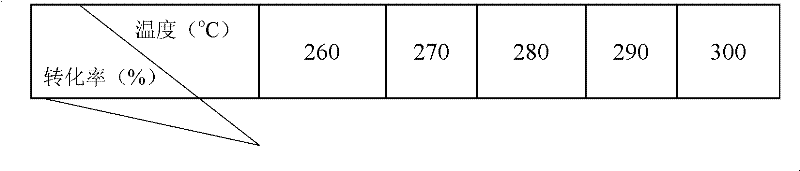

[0017] Table 1: Carrier physical data

[0018] carrier name

[0019] It can be seen from Table 1 that the composite carrier has stronger lateral compressive stre...

Embodiment 2

[0021] This example is the preparation method of alumina-activated carbon composite carrier loaded Ni-Mo catalyst (marked as NiMo / AAC).

[0022] The loading of catalyst active components adopts co-impregnation method. 0.7 g Ni(NO 3 ) 2 ·6H 2 O and 3.62 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to distilled water and vigorously stirred until completely dissolved, and then weighed 1.4 g of the alumina-activated carbon composite carrier prepared in Example 1 that was crushed to 40-60 mesh. Add the support to the prepared metal salt solution at room temperature. Soak for 24 hours at room temperature. The moisture was evaporated under reduced pressure, dried at 105°C for 3 hours, and then calcined at 400°C in a nitrogen atmosphere for 4 hours to obtain a Ni-Mo catalyst supported on an alumina-activated carbon composite carrier. where MoO 3 The loading amount is 21.06% (mass fraction), and the NiO loading amount is 8.94% (mass fraction).

Embodiment 3

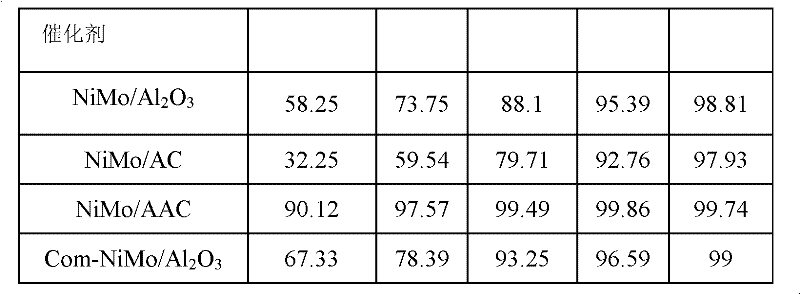

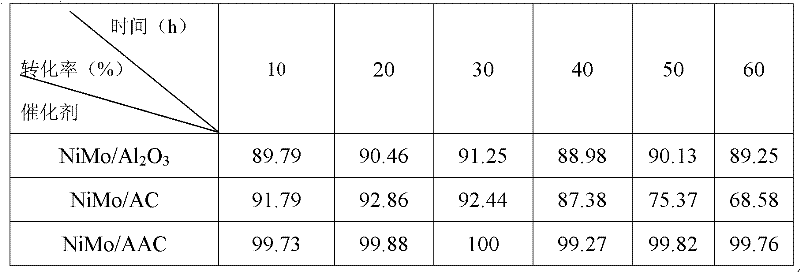

[0024] This example is the evaluation method and result of the hydrodesulfurization activity of the catalyst of the present invention.

[0025] The hydrodesulfurization reaction is carried out on a stainless steel trickle bed reaction device. Weigh 1 gram of 40-60 mesh catalyst and 1 gram of quartz sand of the same particle size and mix it evenly, then add it to the middle of the reaction tube, and use quartz sand as support up and down. The catalyst was presulfided prior to the hydrodesulfurization reaction with 3% CS 2 / Decalin as vulcanizing agent, pressure 3.0MPa, liquid hourly space velocity 3.0h -1 , hydrogen oil ratio 500Nm 3 / m 3 . Then the temperature was raised from room temperature to 300°C at a rate of 10°C / min, and vulcanized at this temperature for 5 hours. Then cool down to the reaction temperature in a hydrogen atmosphere. The hydrodesulfurization activity of the catalyst was evaluated by switching the sulfurized oil to a 1wt% solution of dibenzothiophen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com