S-loaded activated carbon for mercury removal from flue gas and preparation method thereof

A technology of sulfur-loaded activated carbon and activated carbon, which is applied in the field of sulfur-loaded activated carbon and the preparation of the activated carbon, and achieves the effects of simple process method, high sulfur content and uniform surface distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

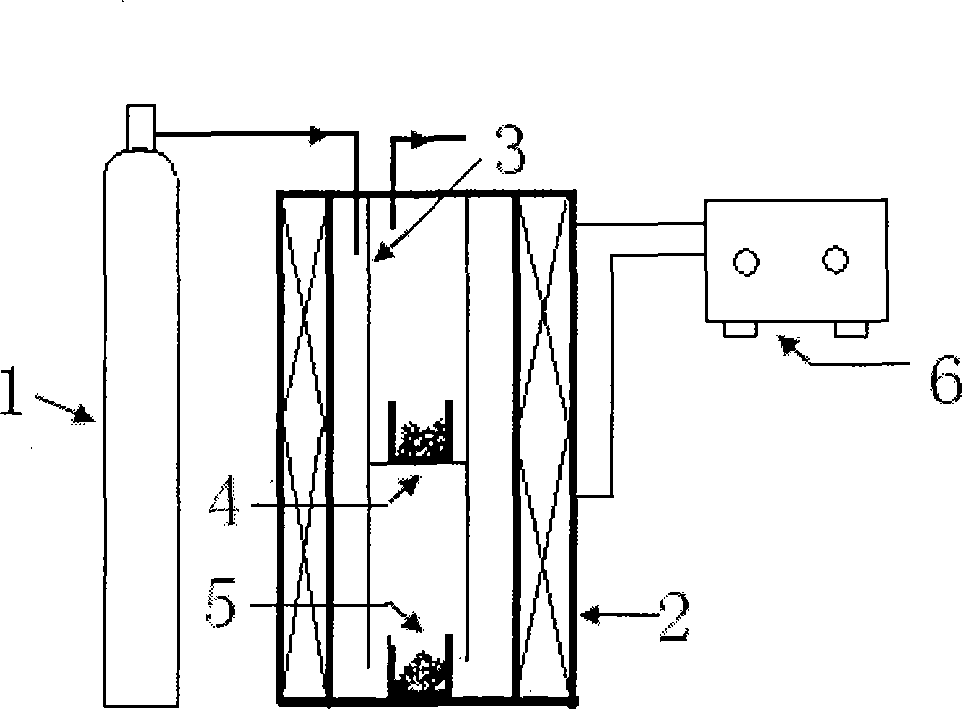

[0022] see figure 1 , the present invention also provides a method for preparing sulfur-loaded activated carbon for flue gas demercuration, the steps are as follows:

[0023] 1) Prepare materials. After rinsing the activated carbon with a particle size of 20-40 mesh with water, put it in a drying oven, bake it at 110°C for 1-2 hours, and set it aside; choose elemental sulfur, and the mass percentage of elemental sulfur in elemental sulfur is more than 99.9%. ;

[0024] 2) Thermal precipitation preparation. Take the heat-resistant container (crucible) filled with the above-mentioned elemental sulfur at the bottom of the thermal precipitation furnace, put the activated carbon into the stainless steel mesh in the middle of the thermal precipitation furnace, and the through hole of the stainless steel mesh is 200 mesh; then, seal the thermal precipitation furnace, and use 2L / min speed into high-purity N 2 30 to 40 minutes, exhaust the air in the heat deposition furnace; then ...

Embodiment 1

[0026] Embodiment 1: take by weighing each 10 grams of dried activated carbon and elemental sulfur and put them into two crucibles respectively, and then put them into a thermal precipitation furnace. Into N 2 30 minutes to vent the air in the furnace; adjust the N 2 The flow rate is 0.5L / min, heated to 550°C, and kept at a constant temperature for 60 minutes, then stop heating; supply protective gas to the furnace temperature to cool. The mass percent content of sulfur in the activated carbon was measured to be 21.34%.

Embodiment 2

[0027] Embodiment 2: Take by weighing 10 grams of dried activated carbon and 5 grams of elemental sulfur and put them into two crucibles respectively, and then put them into a thermal precipitation furnace. The order of placement is that the activated carbon crucible is on the top and the sulfur crucible is on the bottom; with a speed of 2L / min Access to N 2 40 minutes to vent the air out of the furnace; adjust N 2 The flow rate is 0.5L / min, heated to 600°C, and kept at a constant temperature for 80 minutes, then stop heating; supply protective gas to the furnace temperature to cool. The mass percent content of sulfur in the activated carbon was measured to be 19.65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com