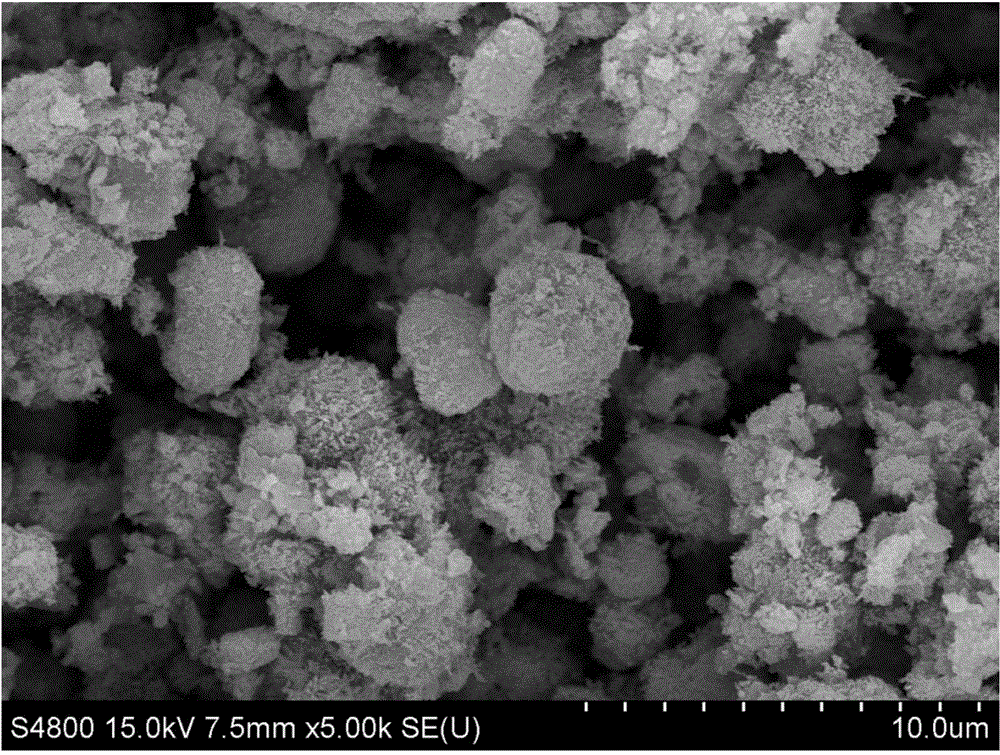

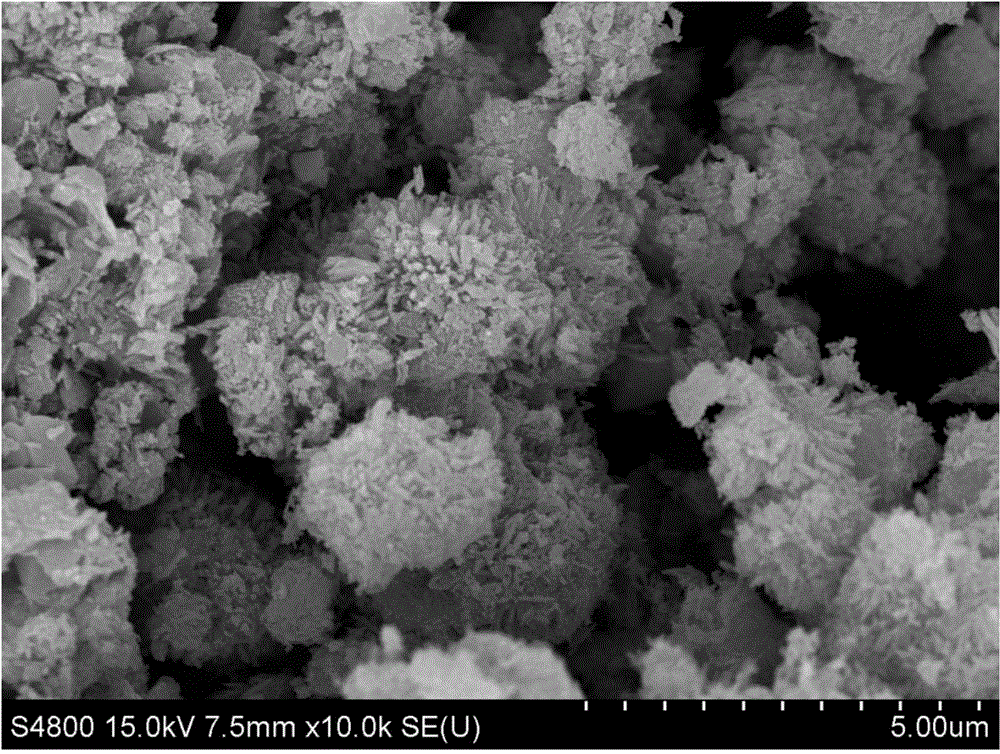

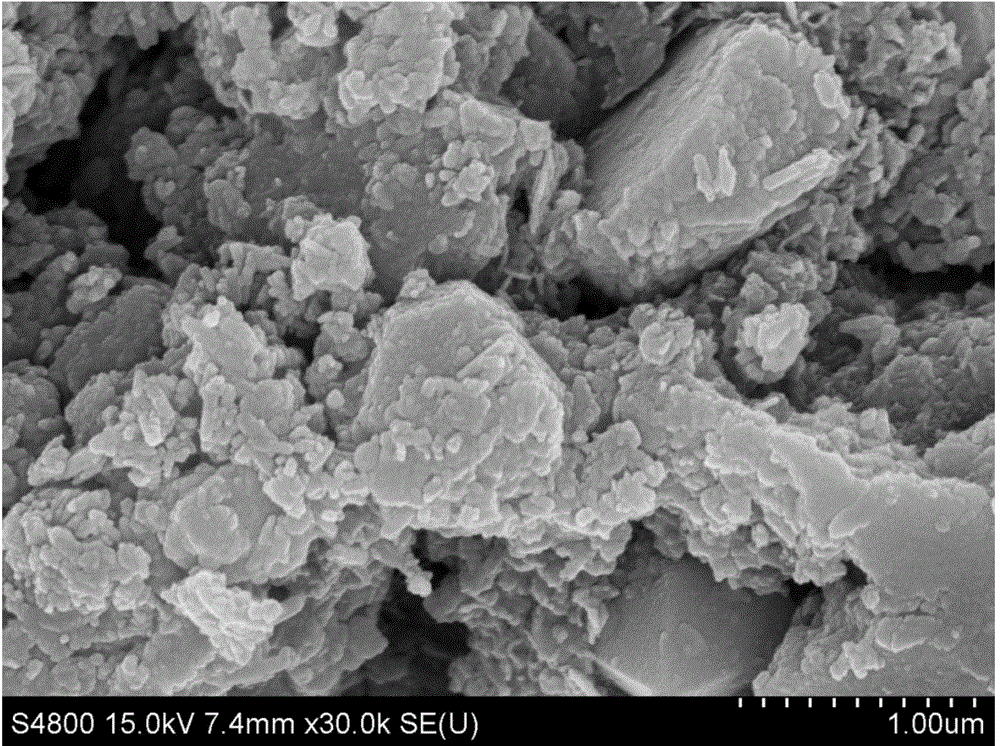

Method for treating chrome-containing wastewater by catalytic reduction of petaloid magnetic iron oxide/molybdenum sulfide composite

A technology of magnetic iron oxide and molybdenum sulfide, applied in reduced water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as hazards and carcinogenicity, and achieve high photocatalytic removal rate, low cost, and high potential The effect of industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for catalytic reduction of petal-shaped magnetic iron oxide molybdenum sulfide complex of the present invention to treat chromium-containing wastewater comprises the following steps in turn: (1) at room temperature, take an appropriate amount of ferrous sulfate heptahydrate and dissolve it in 10-20 ml of deionized water , stirred until transparent to obtain solution 1; (2) at room temperature, take an appropriate amount of sodium chlorate and dissolve it in 15-25 ml of deionized water, stir until transparent to obtain solution 2; (3) keep the concentrations of solutions 1 and 2 at 0.3-2 0.7mol L -1 And 0.1~0.3mol L -1 ; (4) under magnetic stirring, add solution 2 dropwise to solution 1 until the solution appears light yellow; (5) then transfer the above mixed solution to an autoclave, and react at 150-200°C for 10-20 hours; (6) react Afterwards, centrifuge to remove unreacted substances, impurities and water to obtain iron oxide, dry it at 60-75°C and grind it...

Embodiment 2

[0048] A method for catalytic reduction of petal-shaped magnetic iron oxide molybdenum sulfide complex of the present invention to treat chromium-containing wastewater comprises the following steps in turn: (1) at room temperature, take an appropriate amount of ferrous sulfate heptahydrate and dissolve it in 10-20 ml of deionized water , stirred until transparent to obtain solution 1; (2) at room temperature, take an appropriate amount of sodium chlorate and dissolve it in 15-25 ml of deionized water, stir until transparent to obtain solution 2; (3) keep the concentrations of solutions 1 and 2 at 0.3-2 0.7mol L -1 And 0.1~0.3mol L -1 ; (4) under magnetic stirring, add solution 2 dropwise to solution 1 until the solution appears light yellow; (5) then transfer the above mixed solution to an autoclave, and react at 150-200°C for 10-20 hours; (6) react Afterwards, centrifuge to remove unreacted substances, impurities and water to obtain iron oxide, dry it at 60-75°C and grind it...

Embodiment 3

[0051] A method for catalytic reduction of petal-shaped magnetic iron oxide molybdenum sulfide complex of the present invention to treat chromium-containing wastewater comprises the following steps in turn: (1) at room temperature, take an appropriate amount of ferrous sulfate heptahydrate and dissolve it in 10-20 ml of deionized water , stirred until transparent to obtain solution 1; (2) at room temperature, take an appropriate amount of sodium chlorate and dissolve it in 15-25 ml of deionized water, stir until transparent to obtain solution 2; (3) keep the concentrations of solutions 1 and 2 at 0.3-2 0.7mol L -1 And 0.1~0.3mol L -1 ; (4) under magnetic stirring, add solution 2 dropwise to solution 1 until the solution appears light yellow; (5) then transfer the above mixed solution to an autoclave, and react at 150-200°C for 10-20 hours; (6) react Afterwards, centrifuge to remove unreacted substances, impurities and water to obtain iron oxide, dry it at 60-75°C and grind it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com