Ordered nanostructure sulphur/mesoporous carbon composite material for anode of lithium ion battery

A composite material and nanostructure technology, applied in battery electrodes, electrode carriers/current collectors, structural parts, etc., can solve the problems of inability to effectively resist polysulfide dissolution, poor stability of lithium-sulfur batteries, and influence on sulfur content and dispersion, etc. problem, to achieve the effect of high sulfur content, high capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

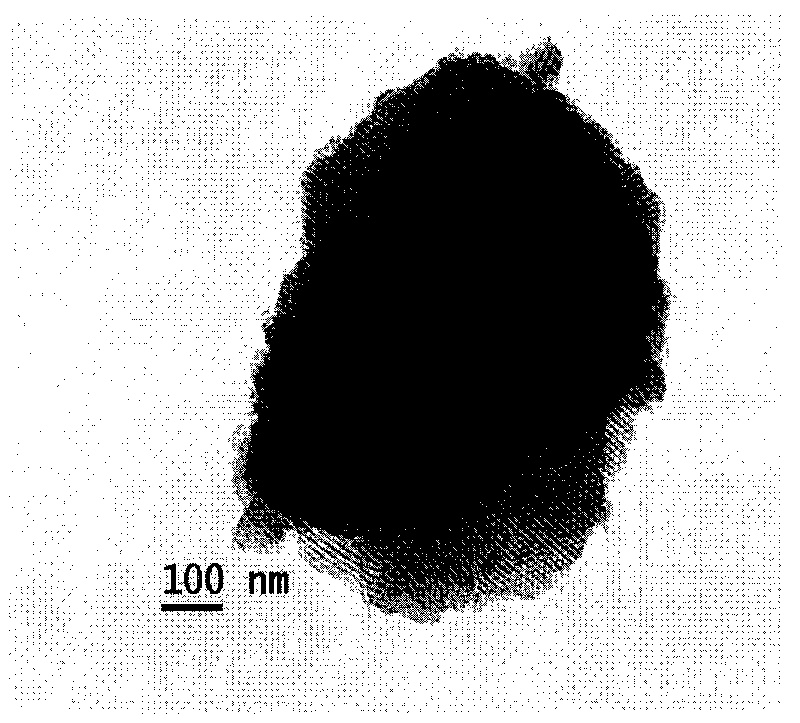

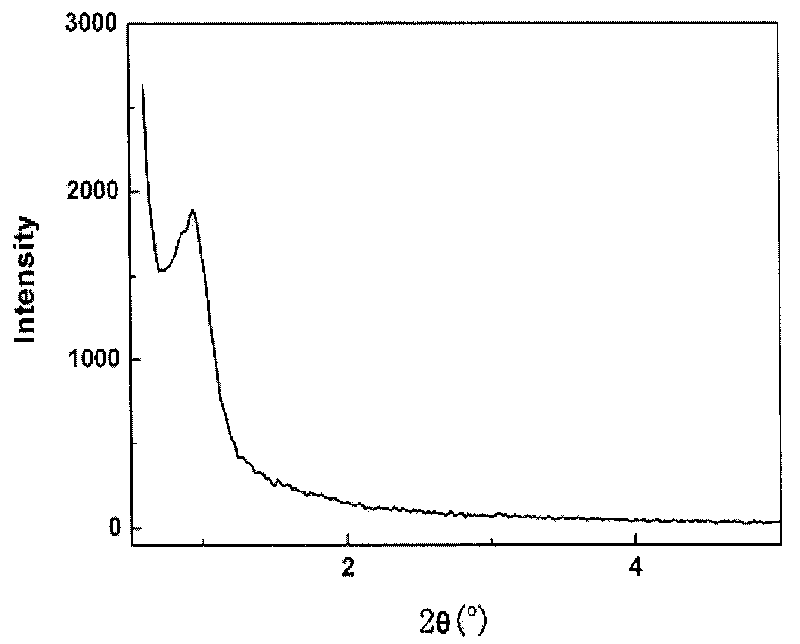

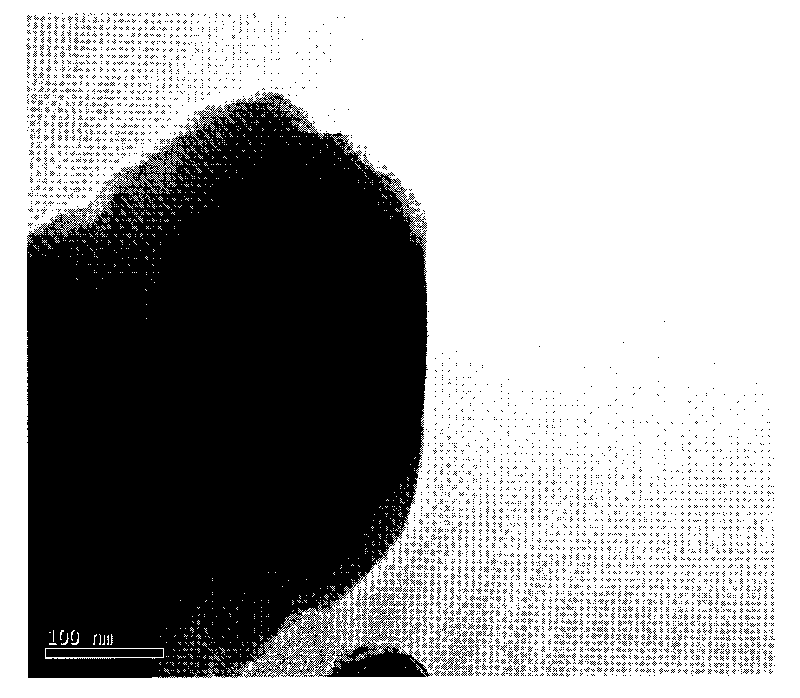

[0023] Example 1: The ordered mesoporous carbon material C-FDU-16 with a pore diameter of 5-9 nm is used as a carrier.

[0024] (1) Preparation of ordered mesoporous carbon FDU-16 by membrane plate method, please refer to Y.Meng, D.Gu, F.Q.Zhang, Y.F.Shi, H.F.Yang, Z.Li, C.Z.Yu, B.Tu, D.Y.Zhao , Angew. Chem. Int. Ed. 2005, 44, 7053-7059. The details are as follows: liquefy phenol at 50°C, take 0.58mL in a clean beaker, add 0.1mL of NaOH solution with a mass fraction of 20%, and magnetically stir for 30min; then add 1.30mL of formaldehyde with a mass fraction of 37% drop by drop Solution, then heated up to 75°C and stirred for 1 hour; dried in vacuum at 40°C-50°C for 24 hours to obtain phenolic resin; took 1.6g of surfactant F127, 1g of phenolic resin 1g0.2mol / L dilute HCl and 10mL of ethanol and continued to stir at 75°C for 2h to obtain Transfer a clear yellow solution to an evaporating dish, and use induced volatilization self-assembly to synthesize the precursor of mesopor...

Embodiment 2

[0029] Example 2: CMK-3 in the mesoporous carbon CMK-n series is used as the carrier.

[0030] (1) Using the hard template method to prepare nano-ordered mesoporous material CMK-3, see S.Jun, S.H.Joo, R.Ryoo., M.Kruk, M.Jaroniec, Z.Liu, T.Ohsuna, O. Terasaki, J. Am. Chem. Soc. 2000, 122, 10712. The specific steps are: 1. Take 1.0g of SBA-15 with a pore diameter of about 6nm as a template, 1.25g of sucrose as a carbon source, dissolve in 5.0mL of water, add 0.14g of concentrated sulfuric acid at the same time, mix ultrasonically for 1h, then heat at 100°C for 12h, then Heating at 120°C for 12 hours; step 2, impregnation again, 0.8000g sucrose, 0.0900g concentrated sulfuric acid, 5.0mL water, the heating conditions are the same as step 1; step 3, nitrogen protection, placed in a tube furnace, heating at 900°C for 6h; step 4 , 20% hydrofluoric acid or 40% mass fraction of alkali-alcohol solution was stirred at room temperature for 24 hours, the purpose of which was to remove sil...

Embodiment 3

[0033] Embodiment 3: SNU-2 in the SNU-n series is used as the carrier.

[0034] (1) Preparation of nano-ordered mesoporous carbon materials by co-synthesis method, see reference H.Q.Li, R.L Liu, D.Y.Zhao, Y.Y.Xiao, Carbon.45(2007) 2628-2635.

[0035] (2) Preparation of nano-ordered sulfur / mesoporous carbon composite material: the mass fraction of configuration sulfur is 10% carbon disulfide solution; the mesoporous carbon is placed on the Buchner funnel, the above-mentioned mixed solution is used as filtrate, and the pump is filtered with circulating water Continuous suction filtration, control time 0.5h-2h, composite materials with different sulfur content can be obtained; the obtained materials are baked in a drying oven at 50°C for 4-6h; nitrogen protection, placed in a tube furnace at 140°C 1h, finally the nano-ordered sulfur / mesoporous carbon composite material is obtained. And assembled into a lithium-sulfur battery, showing excellent electrochemical performance.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com