System and method of blending combustion of coal type with low ash melting point in coal-fired utility boiler

A coal-fired power station, ash melting point technology, applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problems of not having premixing conditions, affecting the operation stability, and the coal yard of the power plant is too small, so as to avoid coking and ensure Safety, the effect of low furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

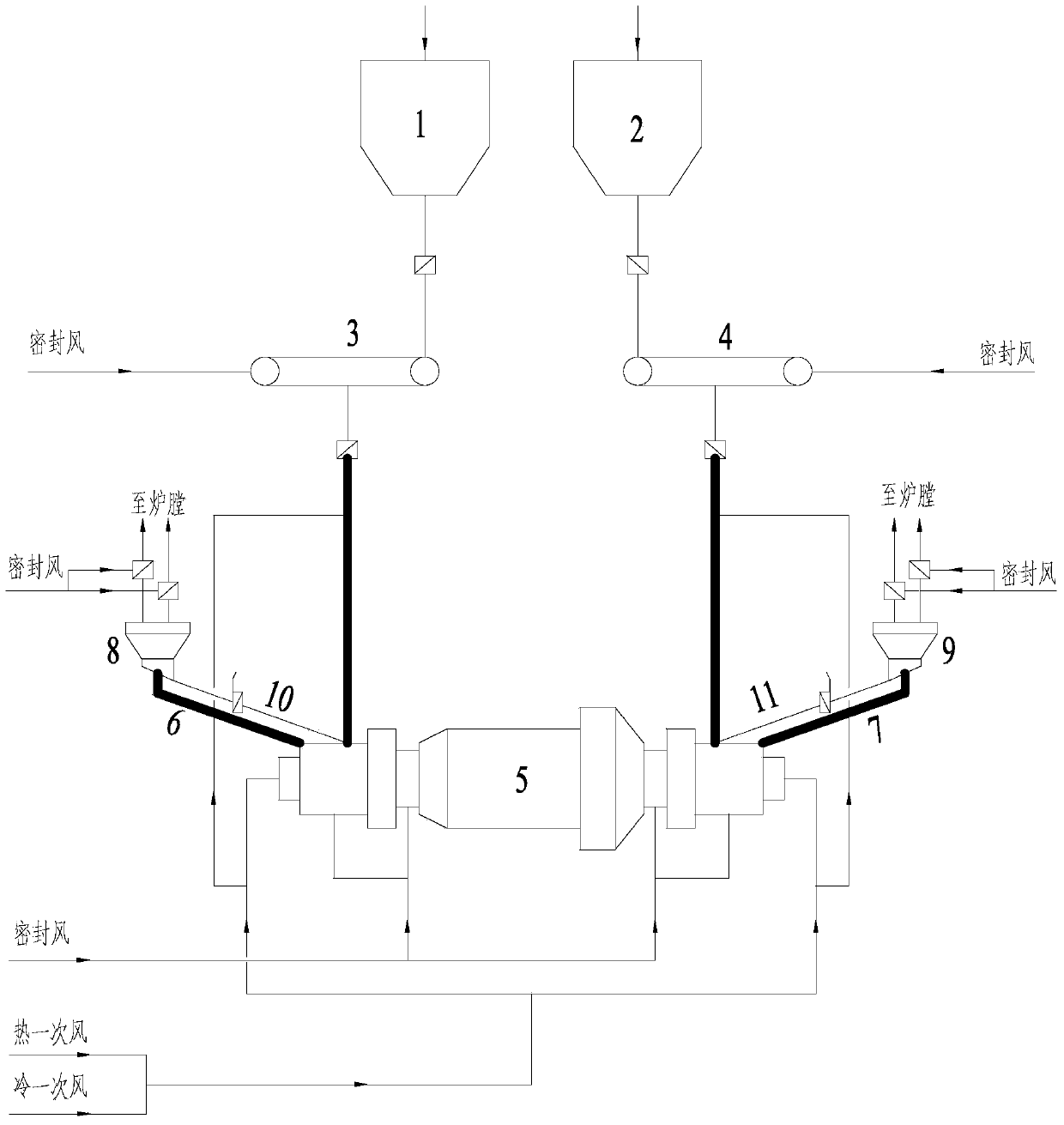

[0030] Such as figure 1As shown, the coal-fired power station boiler of the present invention is mixed with low ash melting point coal type system, and the outlet of the first raw coal bunker 1 for providing low ash melting point coal type is connected to the entrance of the first coal feeder 3, and the first coal feeder 3 The outlet of the double-inlet and double-outlet steel ball coal mill 5 is connected to the first inlet of the double-inlet and double-outlet steel ball coal mill 5, and the first outlet of the double-inlet and double-outlet steel ball coal mill 5 is connected to the inlet of the first separator 8 through the first powder outlet pipe 6, and the first separator The first outlet of 8 is connected to the inlet of the burner in the furnace, and the second outlet of the first separator 8 is connected to the first inlet of the dou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com