Primary combustion chamber of refuse incinerator

A waste incinerator and combustion chamber technology, applied in the field of incinerators, can solve the problems of harsh working environment, affecting continuous operation, unfavorable on-site operation, etc., so as to solve the problem of coking in the furnace, reduce the waiting time for shutdown and feeding, and prevent the occurrence of ash. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

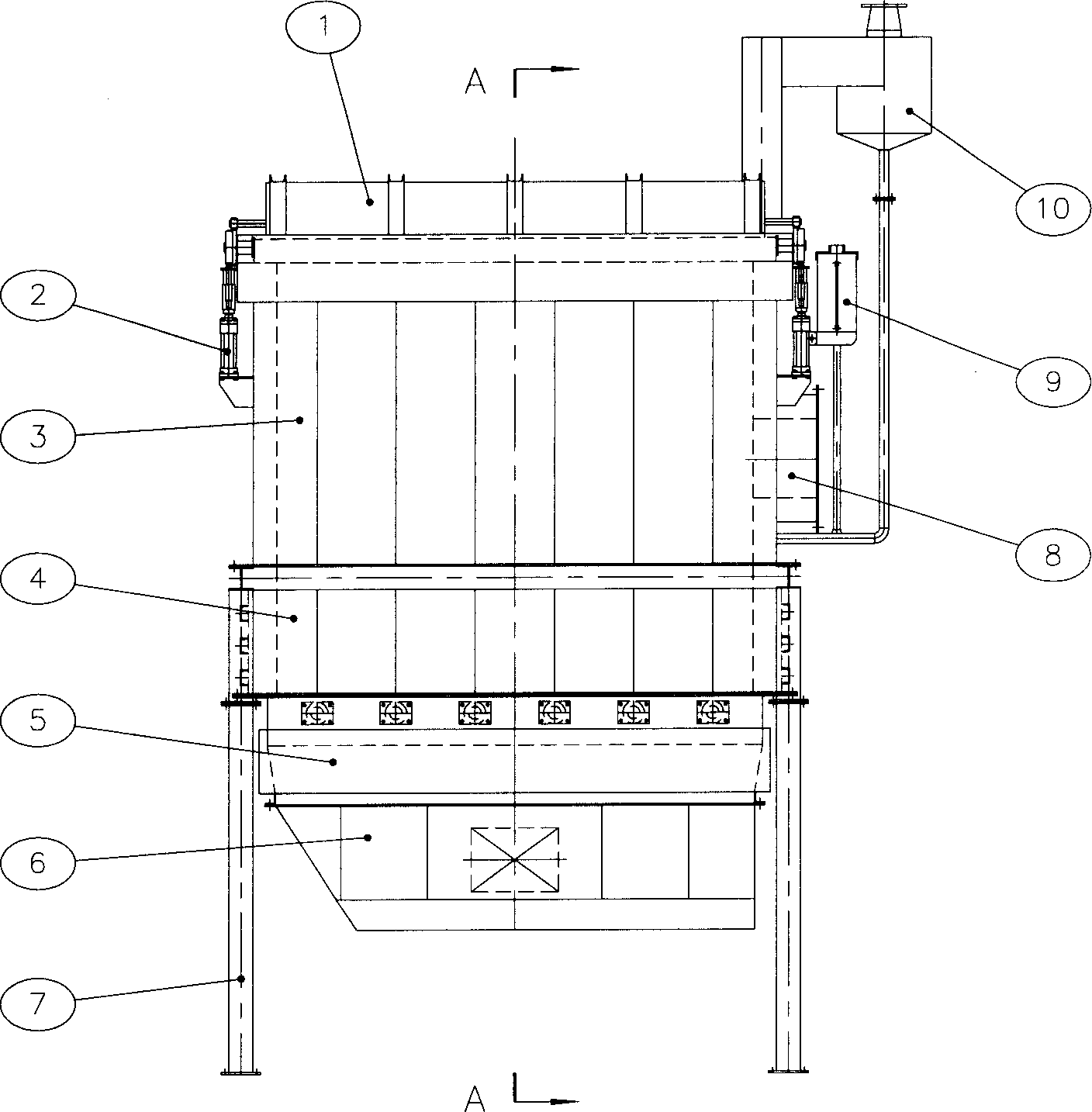

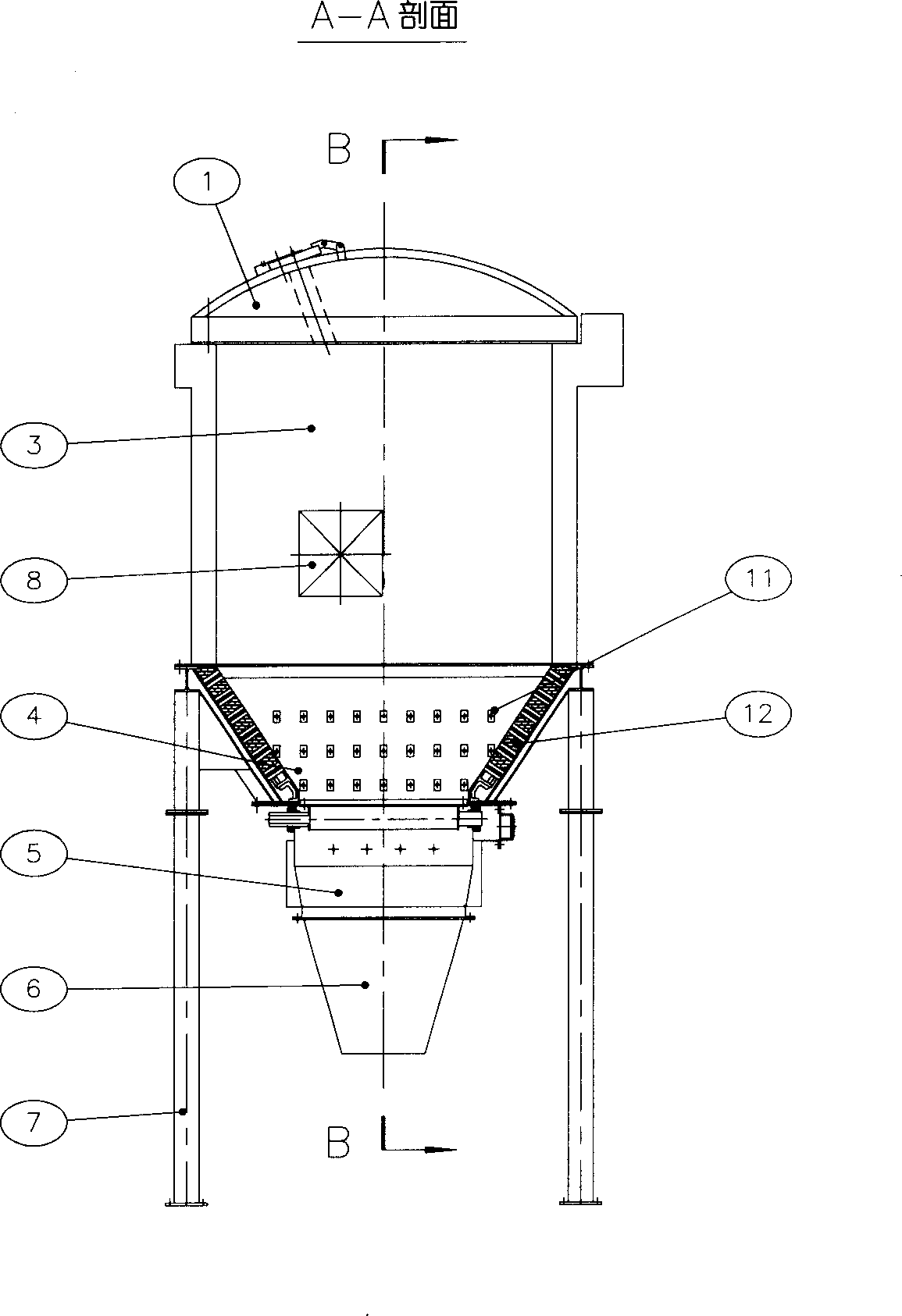

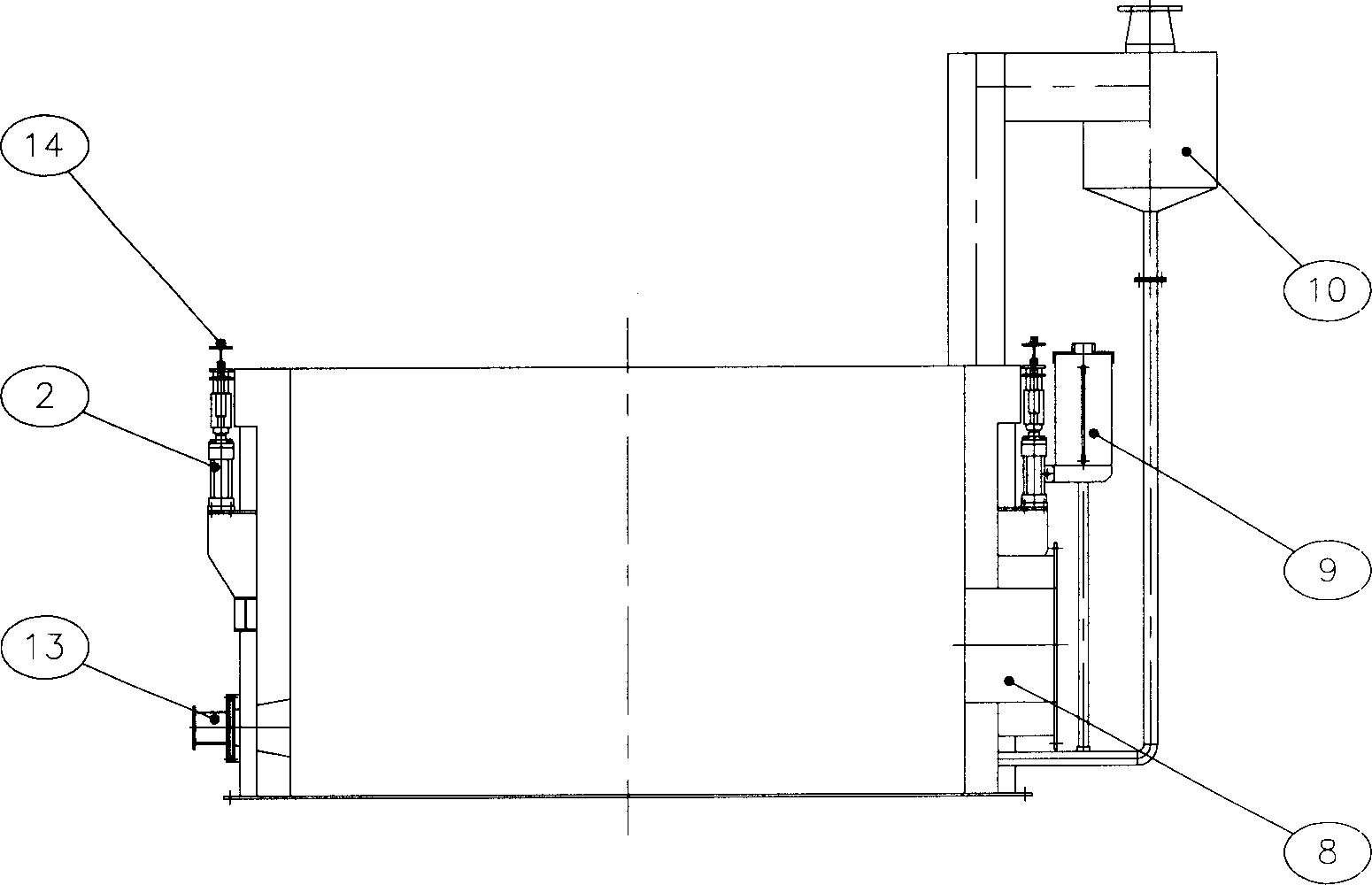

[0015] When feeding, the top cover 1 is lifted by the hydraulic device 2 and slides to one side through the guide rail 14. After the garbage is added to the furnace, the top cover 1 slides back to its original position and is tightly sealed with the furnace body 3. The furnace is composed of the top cover 1 and the furnace body 3. , hearth 4, grate device 5 components. The garbage is ignited through the ignition of the burner, and the supply of combustion-supporting air is controlled, so that the garbage is incompletely burned in the furnace to generate combustible smoke, which enters the secondary combustion chamber through the smoke outlet 8 to continue burning.

[0016] The top cover 1 and the furnace body 3 are composed of double-layer steel plates. Cooling water is added to the interlayer, and the water level is controlled by the expansion tank 9, and a certain steam space is reserved in the water-cooled wall, and part of the heat is taken away by water evaporation, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com