Rice husk boiling hot blast stove

A technology of hot blast stove and chaff, which is applied in the field of chaff boiling hot blast stove, which can solve the problems of incomplete combustion, uneconomical use, large environmental pollution, etc., and achieve the effect of reducing treatment costs and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

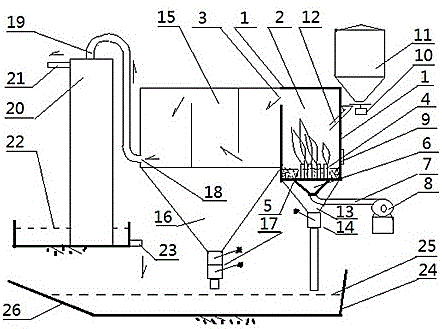

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] In the drawings: Boiling hot blast furnace body 1, combustion chamber 2, combustion chamber air outlet 3, air cap 4, refractory mud protective layer 5, blower box 6, blast pipe 7, blower 8, maintenance observation door 9, disc feeding Machine 10, chaff silo 11, chaff feeding pipe 12, ash hopper under boiling hot blast stove 13, ash discharge valve 14, hot air exchange chamber 15, ash hopper under exchange chamber 16, double ash discharge valve 17, exhaust Mouth 18, exhaust pipe 19, water bath dust removal tower 20, dust removal tower exhaust pipe 21, dust removal tower pool 22, dust discharge mud port 23, wet ash pool 24, pool water level line 25, ash discharge slope 26; It is characterized in that: The boiling hot blast stove body 1 is provided with a combustion chamber 2 .

[0040] The air outlet 3 of the combustion chamber is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com