Preparation method for cathode material of lithium ion battery

A lithium-ion battery and cathode material technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in reaching high temperature, and achieve the effect of low furnace temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

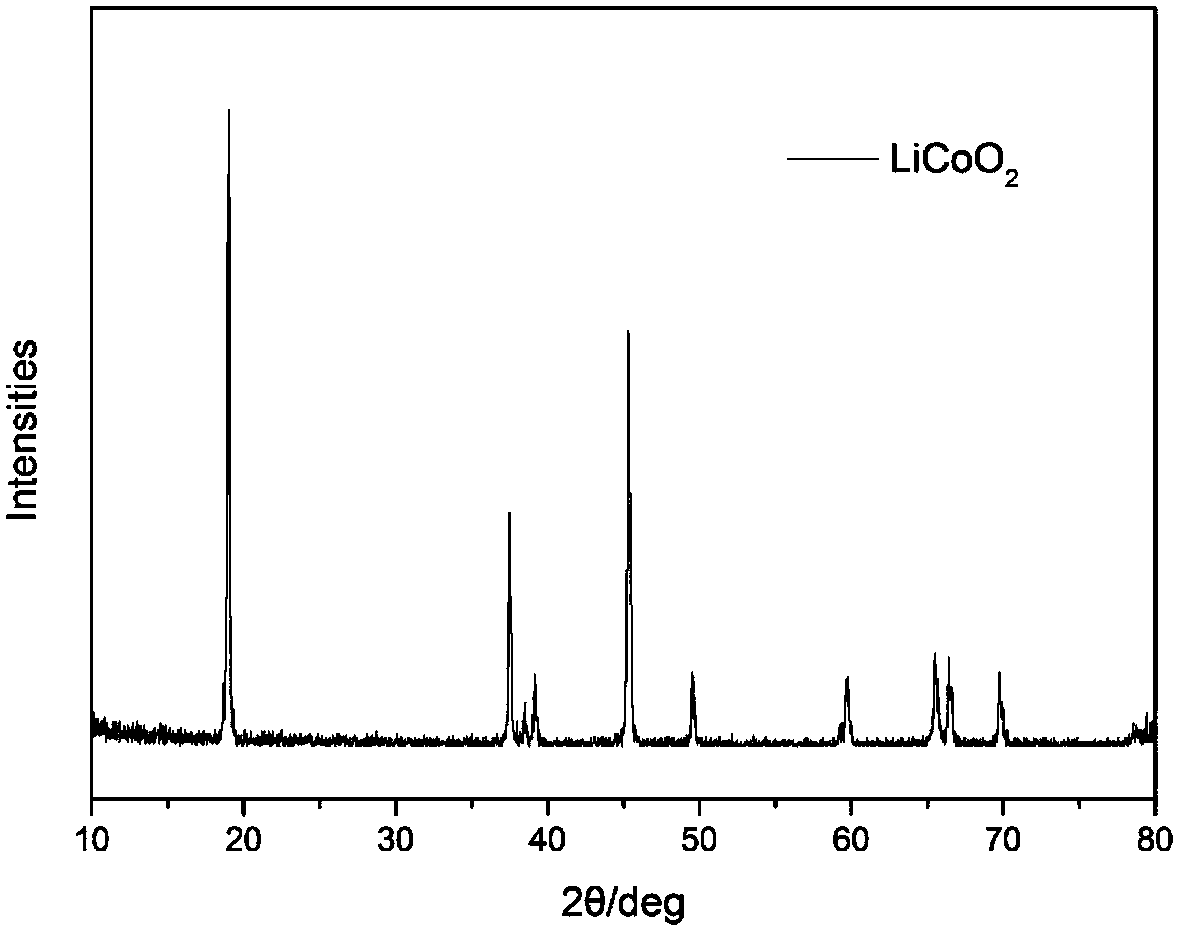

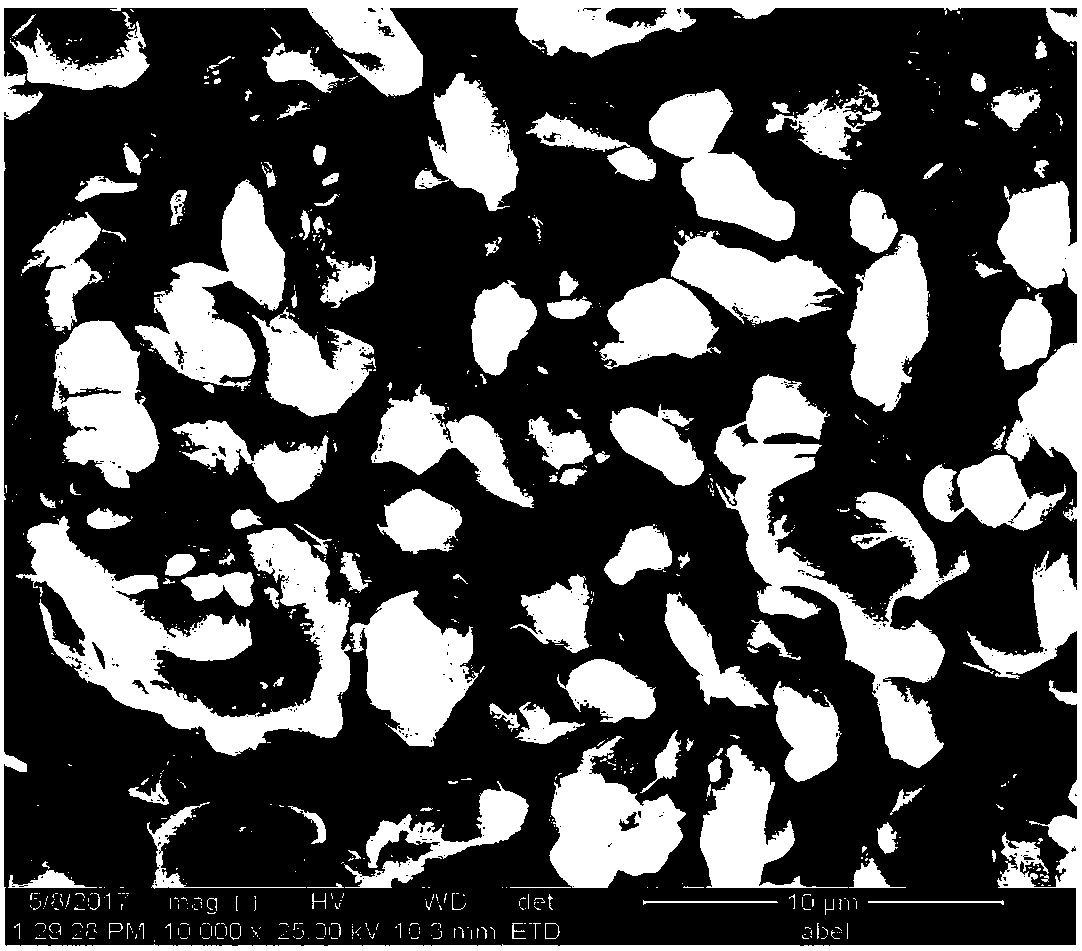

Embodiment 1

[0028] By LiCoO 2 The stoichiometric ratio of the (LCO) molecular formula weighs Li 2 CO 3 、Co 2 o 3 , add ethanol, ball mill for 10 hours, and dry to obtain the LCO positive electrode material precursor powder, grind evenly, put it into a mold after drying, and press it, and apply an electric field to the precursor powder through the wires at both ends of the mold after pressing. The mold was then placed in a tube furnace at 5 °C min -1 The heating rate is to raise the furnace temperature from room temperature to 230°C, and when the temperature rises to 230°C, the temperature is constant, and 70V cm is applied to the LCO cathode material precursor through a constant external power supply. -1 The electric field is used for current-assisted high-temperature synthesis, and the current will change rapidly; the control current rises to 27mA mm -2 , maintain furnace temperature and at 27mA mm -2 Sintering under constant current for 2h, then cutting off the circuit and cooling...

Embodiment 2

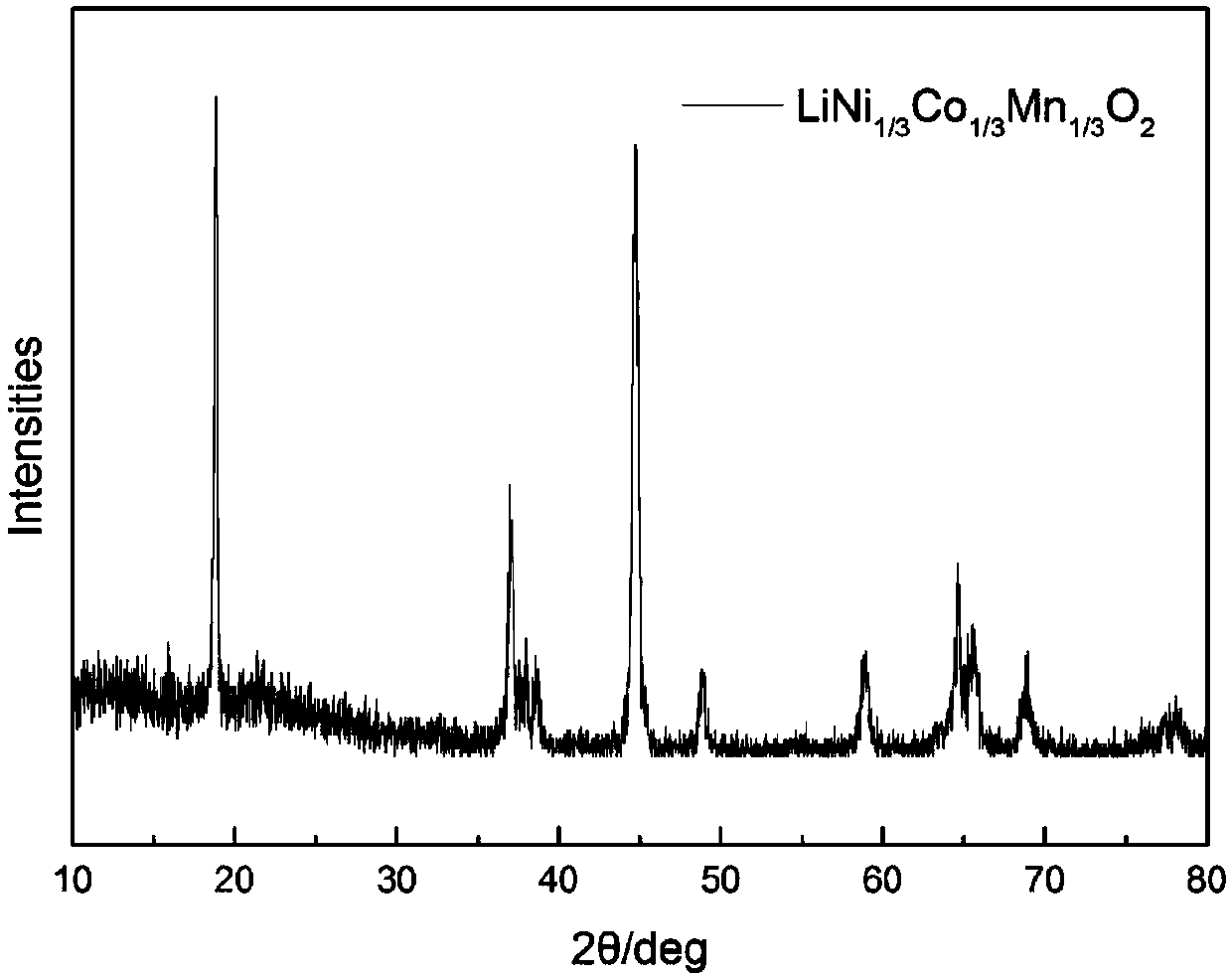

[0030] Press LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 (LNCMO) The stoichiometric ratio of the molecular formula weighs Li 2 CO 3 、NiCO 3 , CoO, MnO, add ethanol, ball mill for 10 hours, and dry to obtain LNCMO cathode material precursor powder, grind evenly, put it into a mold after drying, and press it, after pressing, apply an electric field to the precursor powder through the wires at both ends of the mold . The mold was then placed in a tube furnace at 5 °C min -1 The heating rate is to raise the furnace temperature from room temperature to 300°C. When the temperature rises to 300°C, the temperature is kept constant, and 70V cm is applied to the LNCMO cathode material precursor through a constant external power supply. -1 The field strength of the current-assisted high-temperature synthesis is carried out, and the current will change rapidly at the same time; the control current rises to 27mA mm -2 , maintain furnace temperature and at 27mA mm -2 Sintering at a constant current...

Embodiment 3

[0032] by LiFePO 4 The stoichiometric ratio of (LFPO) molecular formula weighs Li 2 CO 3 , FeC 2 o 4 , NH 4 h 2 PO 4 , add ethanol, ball mill for 10 hours, and dry to obtain LFPO positive electrode material precursor powder, grind evenly, put it into a mold after drying, and press it, and apply an electric field to the precursor powder through the wires at both ends of the mold after pressing. The mold was then placed in a tube furnace at 5 °C min -1 The heating rate is to raise the furnace temperature from room temperature to 380°C. When the temperature rises to 380°C, the temperature is constant, and 100V cm is applied to the LFPO cathode material precursor through a constant external power supply. -1 The field strength of the current-assisted high-temperature synthesis is carried out, and the current will change rapidly at the same time; the control current rises to 27mA mm -2 , maintain furnace temperature and at 27mA mm -2 Under constant current sintering for 2h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com