Room temperature ceramic sintering method and ceramic

A sintering method and ceramic technology, which is applied in the field of ceramics sintered by the room temperature ceramic sintering method, can solve problems such as blast furnace temperature, achieve the effects of reducing furnace temperature and energy consumption, the method is simple and easy, and energy consumption is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

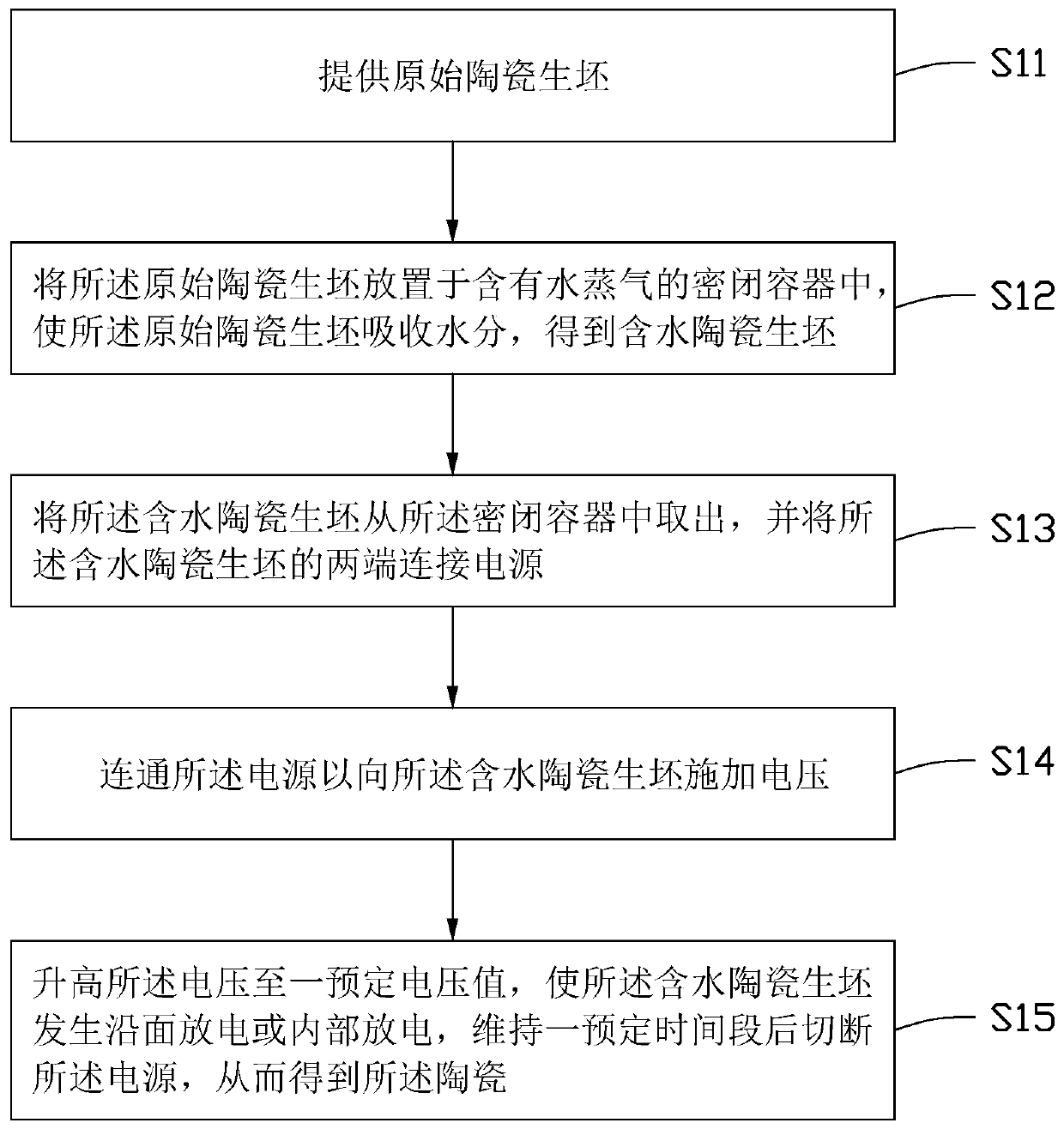

Method used

Image

Examples

Embodiment 1

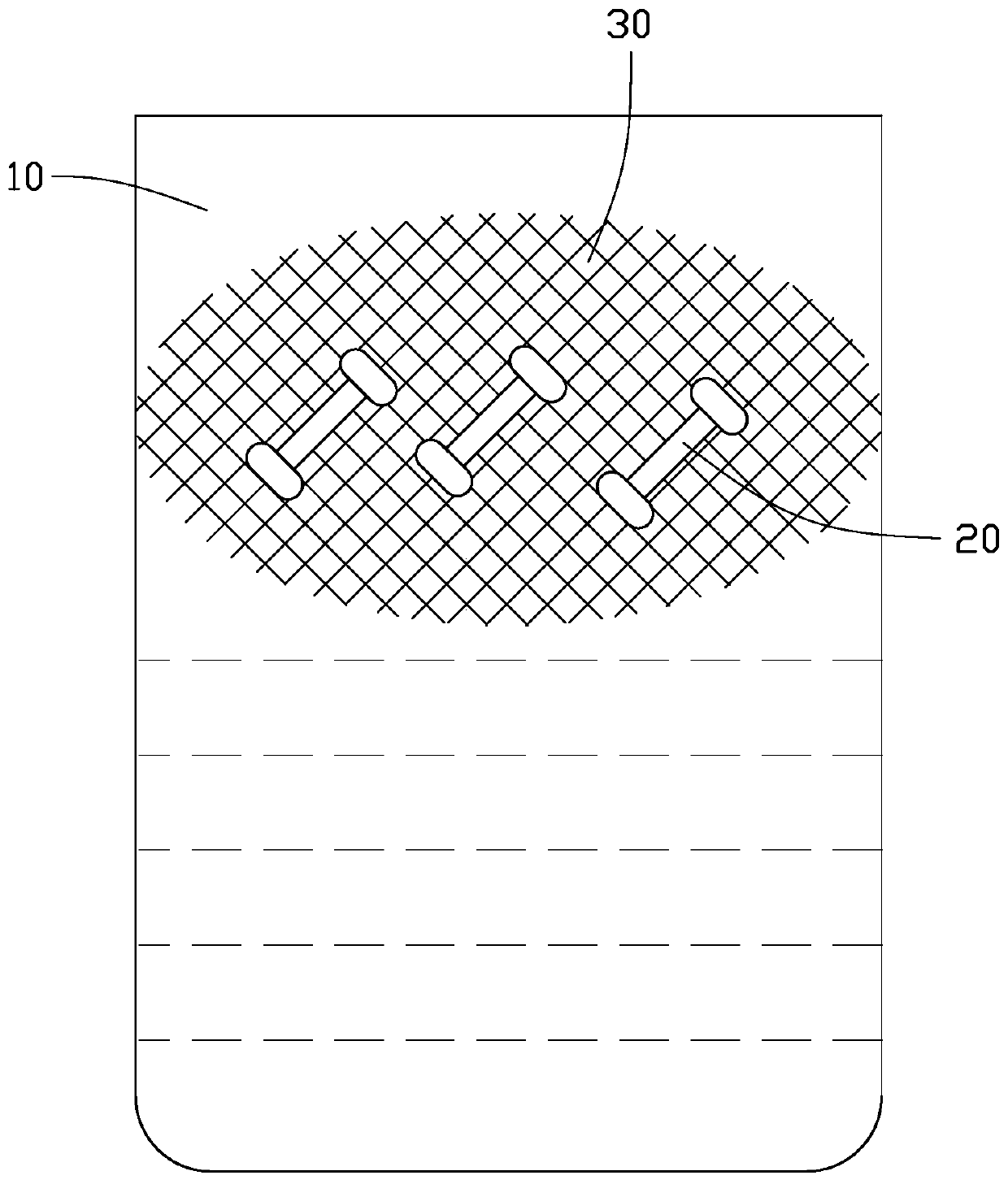

[0059] The first step is to put a zinc oxide ceramic green body in the shape of an I-shape into such figure 2 After standing in the beaker shown for about 20 hours, the water content of the obtained water-containing ceramic green body reached 4.32%. Wherein, the middle part of the I-shaped ceramic green body has a thickness of 1.7mm, a length of 21mm, and a width of 3.3mm.

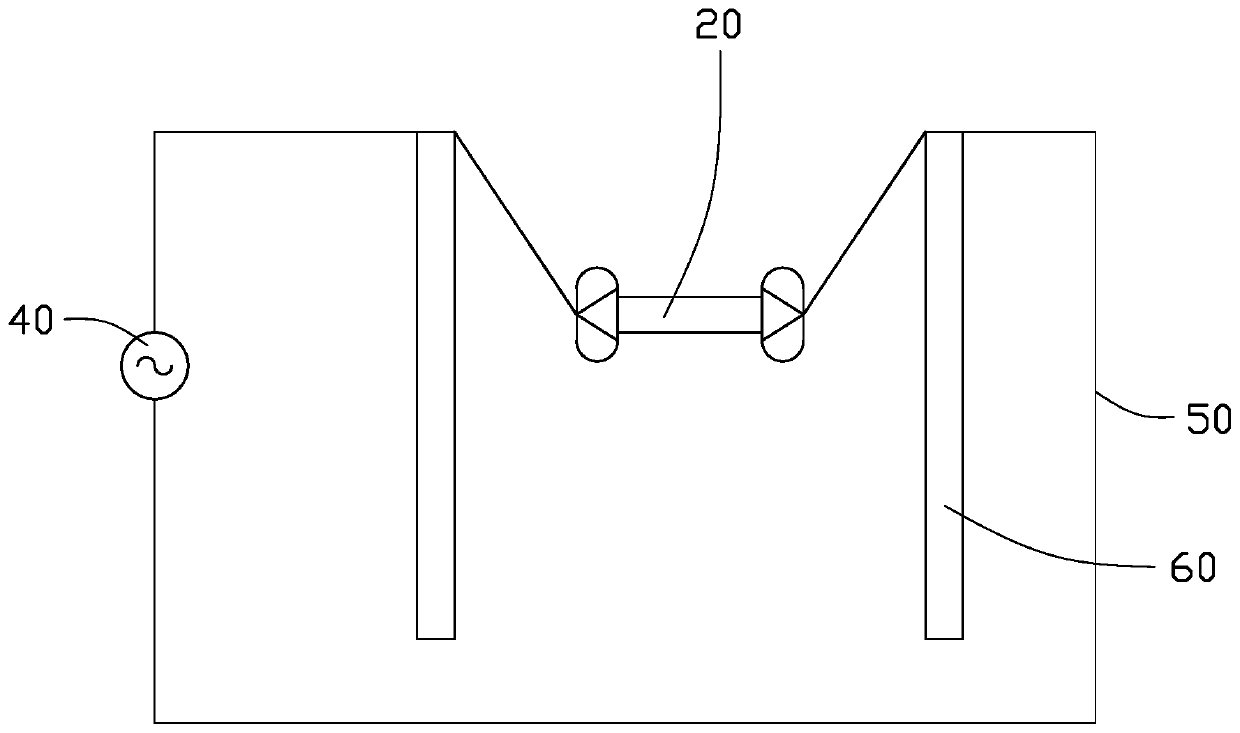

[0060] In the second step, wires are wound on both ends of the water-containing ceramic green body, and the wires are connected to an AC power source, and the wires are fixed on a fixed support to suspend the water-containing ceramic green body.

[0061] The third step is to turn on the power supply, and then rapidly increase the voltage at a rate of 1kV / s until the voltage at both ends of the water-containing ceramic green body suddenly drops, and the current flowing through the water-containing ceramic green body suddenly rises, maintaining the voltage and current No change, the power supply was discon...

Embodiment 2

[0063] The difference from Example 1 is that the shape of the ceramic green body in the first step is a cylinder, wherein the diameter is 3 mm and the length is 22 mm, and it is placed in a beaker for about 36 hours, and the moisture content of the obtained hydrous ceramic green body reaches 6.12%. . A DC power supply is used in the second step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com