Method for assembling printed circuit board

A technology for a printed circuit board and an assembly method, which is applied in the direction of assembling printed circuits with electrical components, and can solve problems such as low efficiency, complex process, and blisters on the surface of metal substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

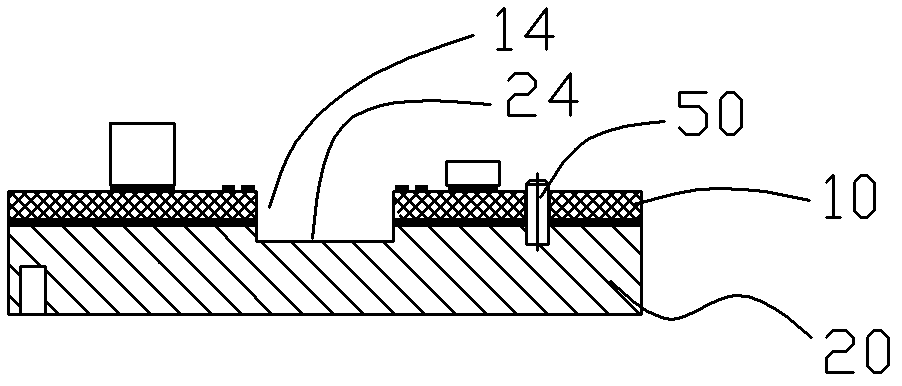

[0020] Aiming at the shortcomings of the prior art, the present invention draws on the high-temperature soldering method and the principle of SMT patch, and provides a new printed circuit board assembly process. The printed circuit board, the power amplifier and the metal substrate are integrated and welded by normal temperature soldering. As a result, the assembly efficiency is improved, the blistering of the metal substrate coating and the deformation of the printed motherboard are avoided, and the ground heat dissipation performance is effectively improved, and the performance of the radio frequency circuit power amplifier is improved.

[0021] The present invention will be further described below in conjunction with the drawings and embodiments.

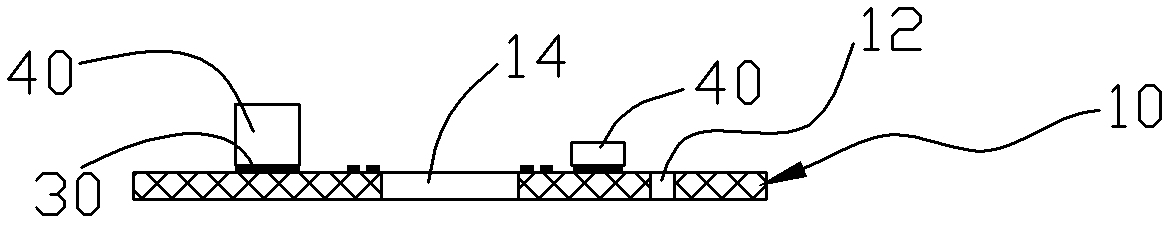

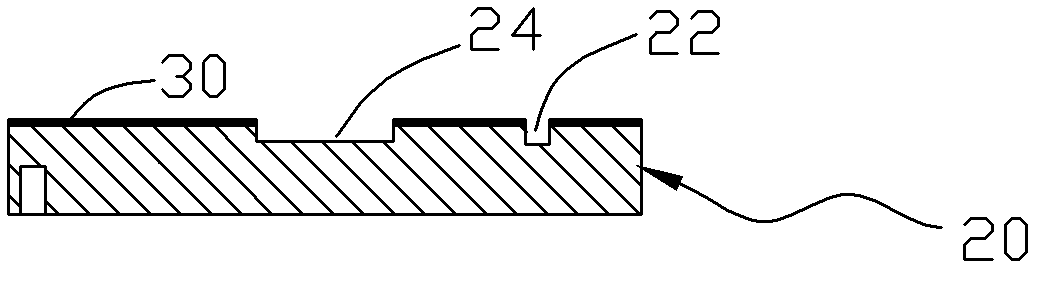

[0022] See Figure 1-6 According to an embodiment of the present invention, a printed circuit board assembly method includes the following steps:

[0023] First, the printed mother board 10 and the metal substrate 20 are provided. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com