Biomass hot water cooking and heating stove with double-layer micro-dynamic fire grates

A technology of biomass and heating stoves, which is applied to furnaces/stoves with hot water devices, household heating, heating methods, etc., can solve problems such as coking and slagging, and achieve the effect of preventing smoke and fire from returning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

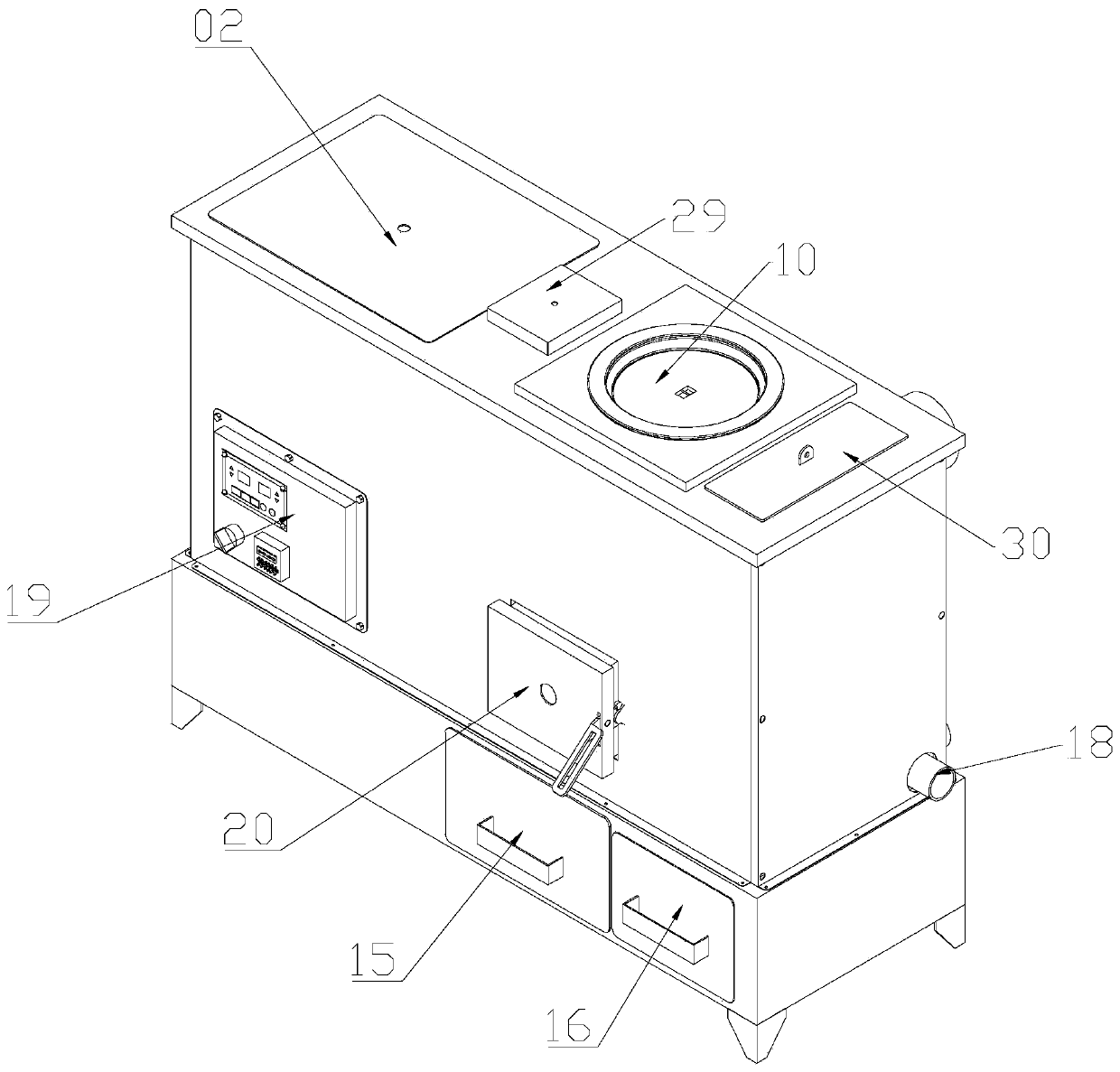

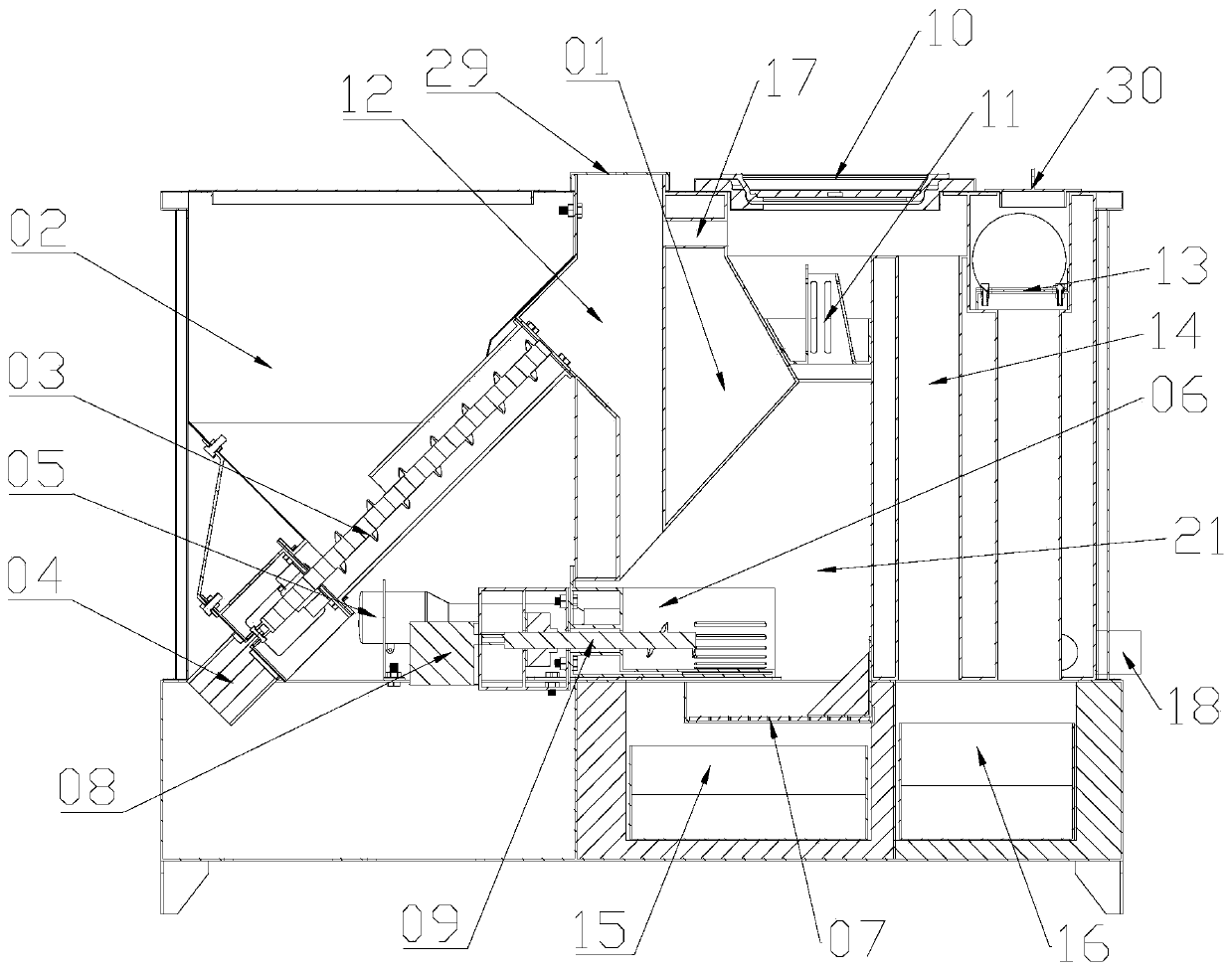

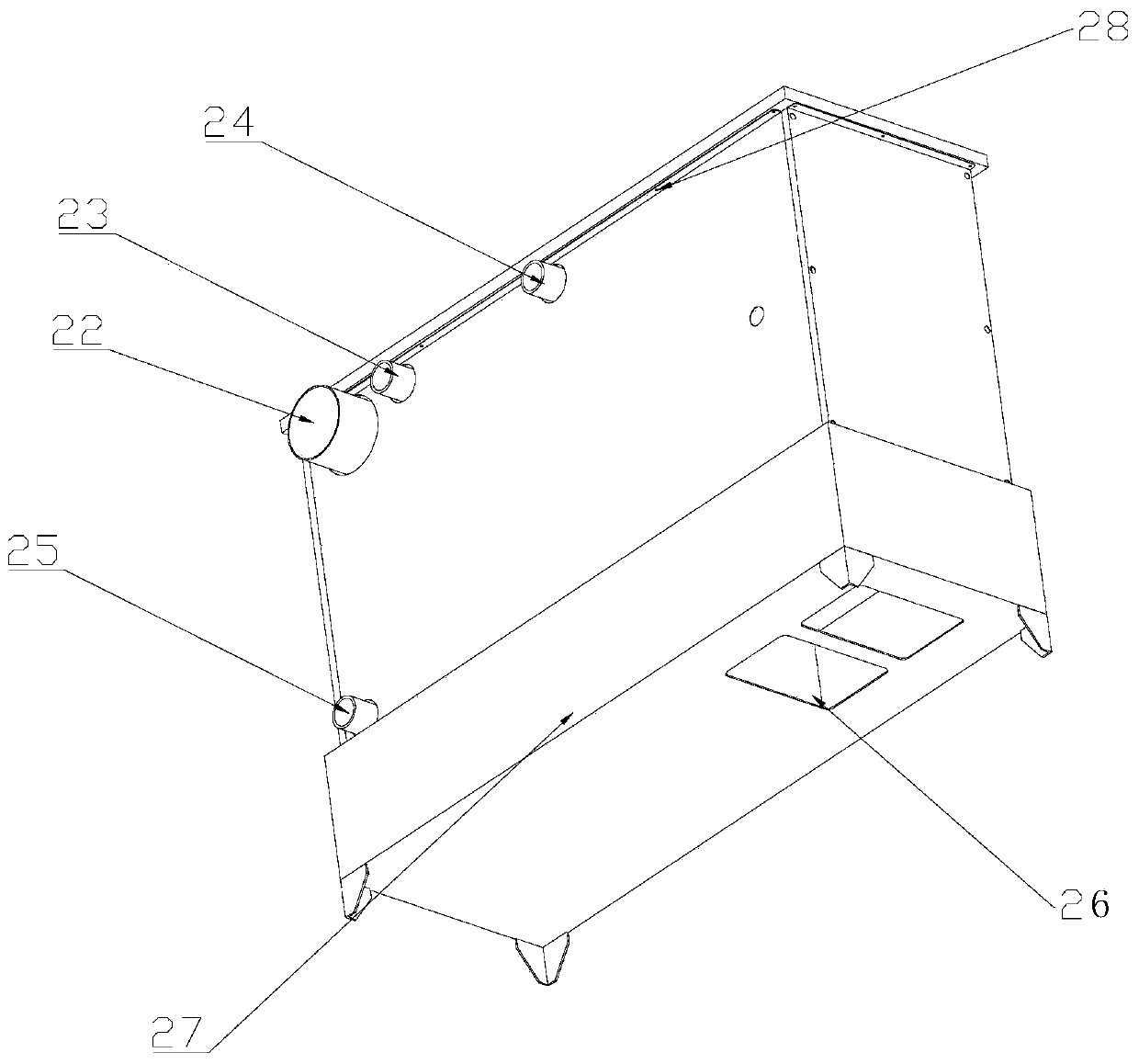

[0025] Such as Figure 1 to Figure 3 As shown, a double-layer micro-dynamic grate biomass hot water cooking and heating furnace provided by the embodiment of the present invention includes a furnace body, a controller system, a feeding anti-backfire system, a slag removal and grate combustion system, and a distribution system. Wind system, heat exchange application system and cleaning and purification system;

[0026] The slag and grate combustion system includes a furnace 21 arranged in the furnace body, a movable grate 6 installed at the bottom of the furnace 21, an igniter 5 for igniting fuel accumulated on the movable grate 6, and a The fixed fire grate 7 below the movable fire grate 6, the slag removal auger 9 for pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com