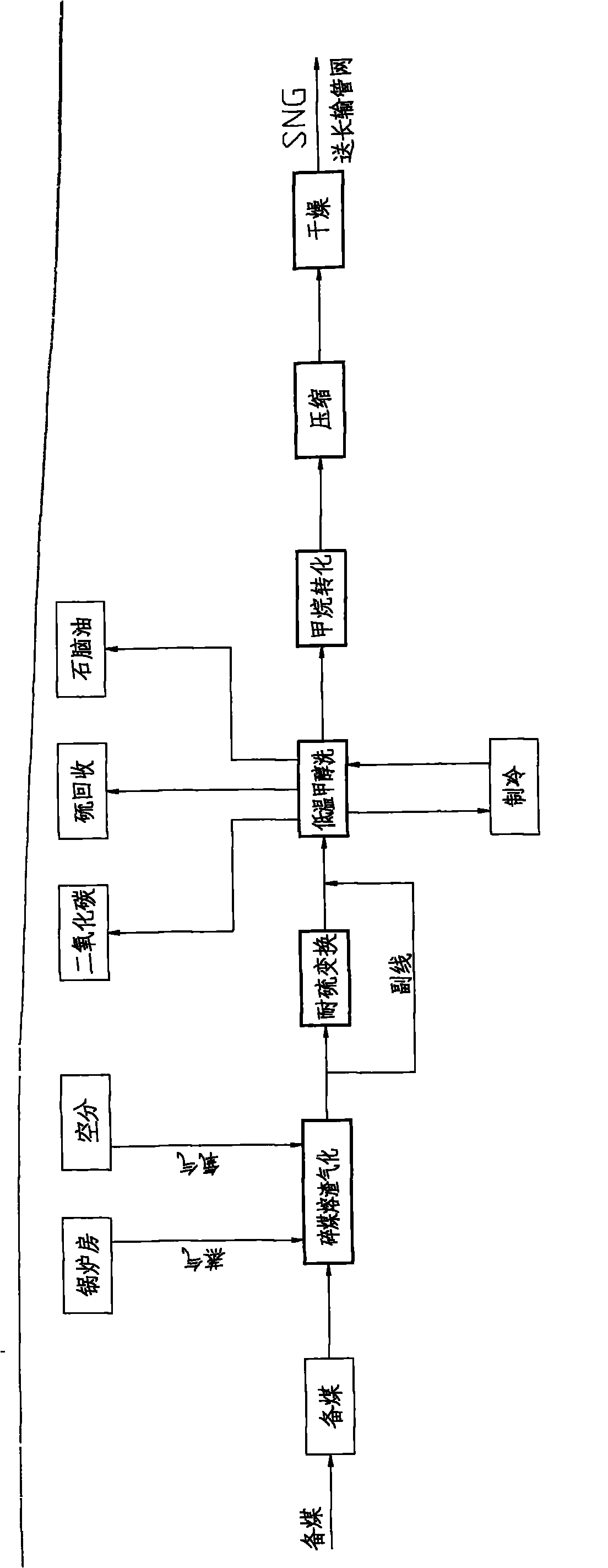

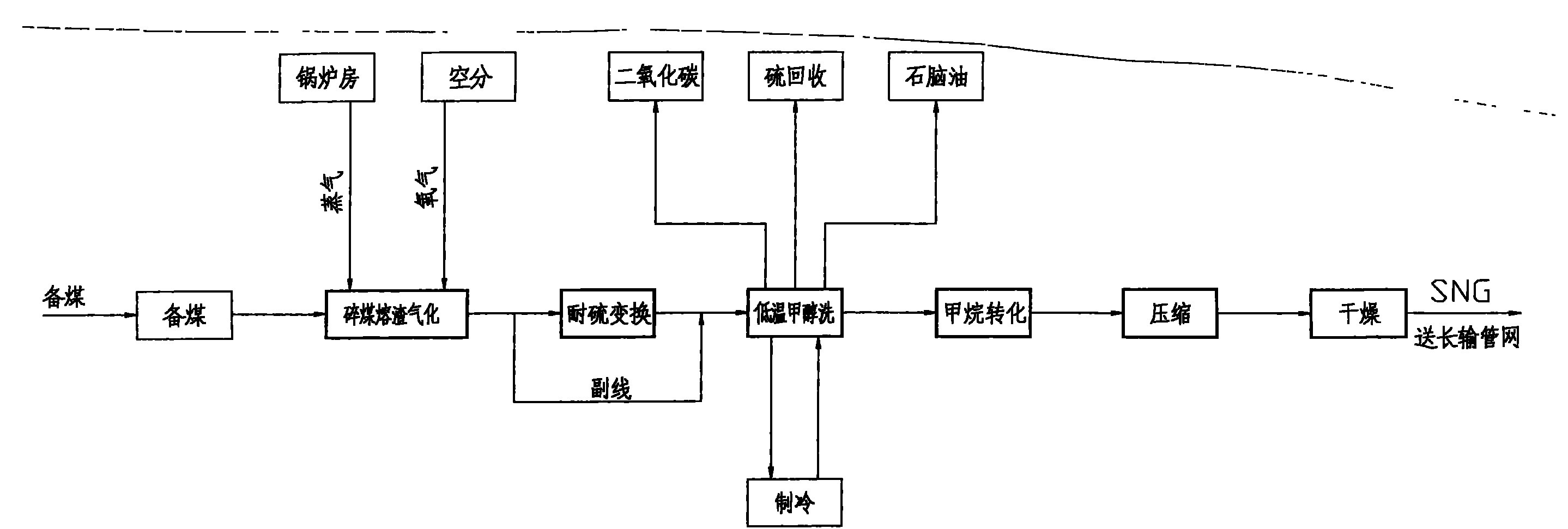

Technique for producing coal natural gas by utilizing crushed coal slag through gasification

A coal-to-natural gas and slag gasification technology, which is applied in combustible gas purification, combustible gas purification/transformation, condensed non-gaseous material gas purification, etc. Long process and other issues, to achieve the effect of high reliability, less auxiliary equipment, stable operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Using lignite, gasification of crushed coal slag to produce CH 4 The crude gas contains CH 4 About 8.0%, CO52%, H 2 26%. After the raw gas is washed and cooled, and the heat is recovered by the waste heat boiler, it enters the sulfur-resistant transformation at 4.5Mpa and 175°C (saturated steam).

[0098] After all the raw gas passes through the pre-transformer, it is divided into two shares, of which about 65% of the raw gas enters the main transformer system, and is transformed under the action of the QCS-04 sulfur-resistant shift catalyst produced by the domestic Qilu Petrochemical Research Institute Keli Chemical Company. The water / gas ratio is about 0.28, the conversion temperature is 220℃, the conversion pressure is 4.4Mpa, and the calculated volumetric air velocity of dry gas is SV 5000h -1 ; Another about 35% of the gas is mixed with the transformed gas without shifting, and the CO content is about 13.5%, and finally through the gas cooler, the 40℃, 4.15MPa shift ga...

Embodiment 2

[0101] Using lignite with a water content of up to 35%, using crushed coal slag gasification to produce CH 4 The crude gas contains about 8.3% CH4, 47.5% CO, H 2 26%. The crude gas is washed and cooled, and the heat is recovered by the waste heat boiler, and then enters the sulfur-resistant transformation at 4.0MPa and 175°C (saturated steam).

[0102] After all the raw gas passes through the pre-changing furnace, it is divided into two streams, of which about 66% of the raw gas enters the main transformer system. A sulfur-resistant shift catalyst with high hydrolysis function is disclosed in Chinese Patent 200410008740.6. The catalyst uses magnesium-aluminum spinel as the carrier, Co-Mo as the active component and the addition of alkali metal promoters. The active component content is CoO 1.8-30%, MoO 37-15%, K 2 The conversion is carried out under the action of a sulfur-resistant shift catalyst with O 6~15%, the water / gas ratio is about 0.40, the shift temperature is 450℃, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com