Solvent reinforced transformation thermal coupling rectification system for separating cyclohexanone and phenol

A technology of solvent strengthening and rectification system, which is applied in the separation/purification, fractionation, and chemical industry of carbonyl compounds. It can solve problems such as inability to separate, difficult wastewater treatment, and inability to achieve efficient recovery of phenol, so as to reduce equipment investment and effectively Conducive to environmental protection, the effect of continuous distillation separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

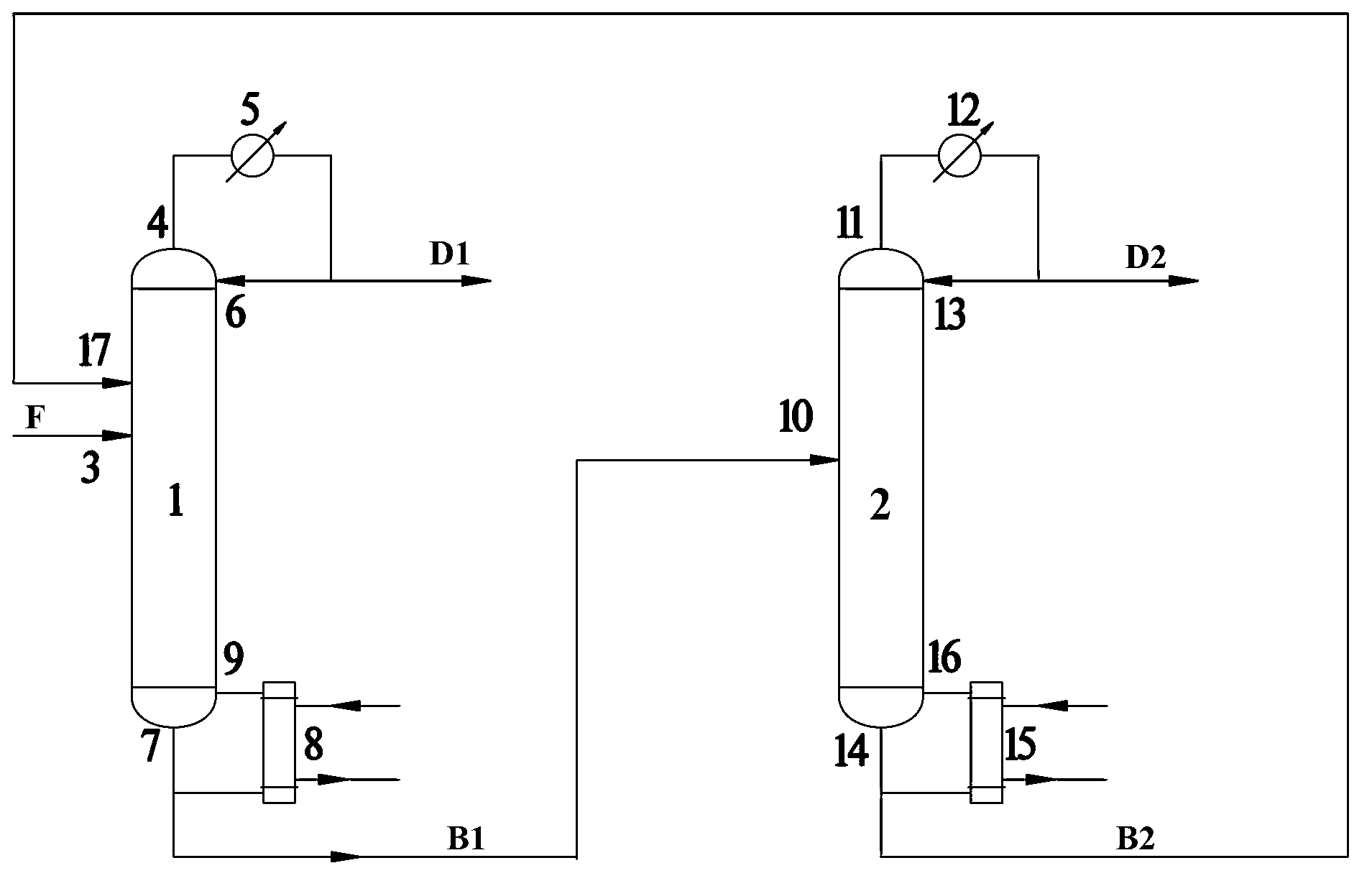

[0053] use as figure 1 The shown twin-tower process flow is an example:

[0054] Phenol content is the cyclohexanone / phenol raw material solution F of 30wt%, and its flow rate is 3kg / h, and circulation stream B2 flow rate is 3.9kg / h, and two stream streams are sent into the first low-pressure rectification column that operating pressure is 3kPa simultaneously 1 is separated, and the tower top obtains the cyclohexanone product D1 that purity is 99.9wt%; The first low-pressure rectifying tower still outlet stream B1 is phenol and solvent azeotrope under 3kPa, and B1 stream will send into operating pressure It is separated by the 260kPa high-pressure rectification tower 2. Because phenol and solvent azeotrope form pressure sensitivity, the phenol content in the phenol and solvent azeotrope under 260kPa is obviously lower than 3kPa when phenol content, obtain the phenol product D2 that purity is 99.9wt% now at high pressure rectification column 2 tower tops, The bottom product s...

Embodiment 2

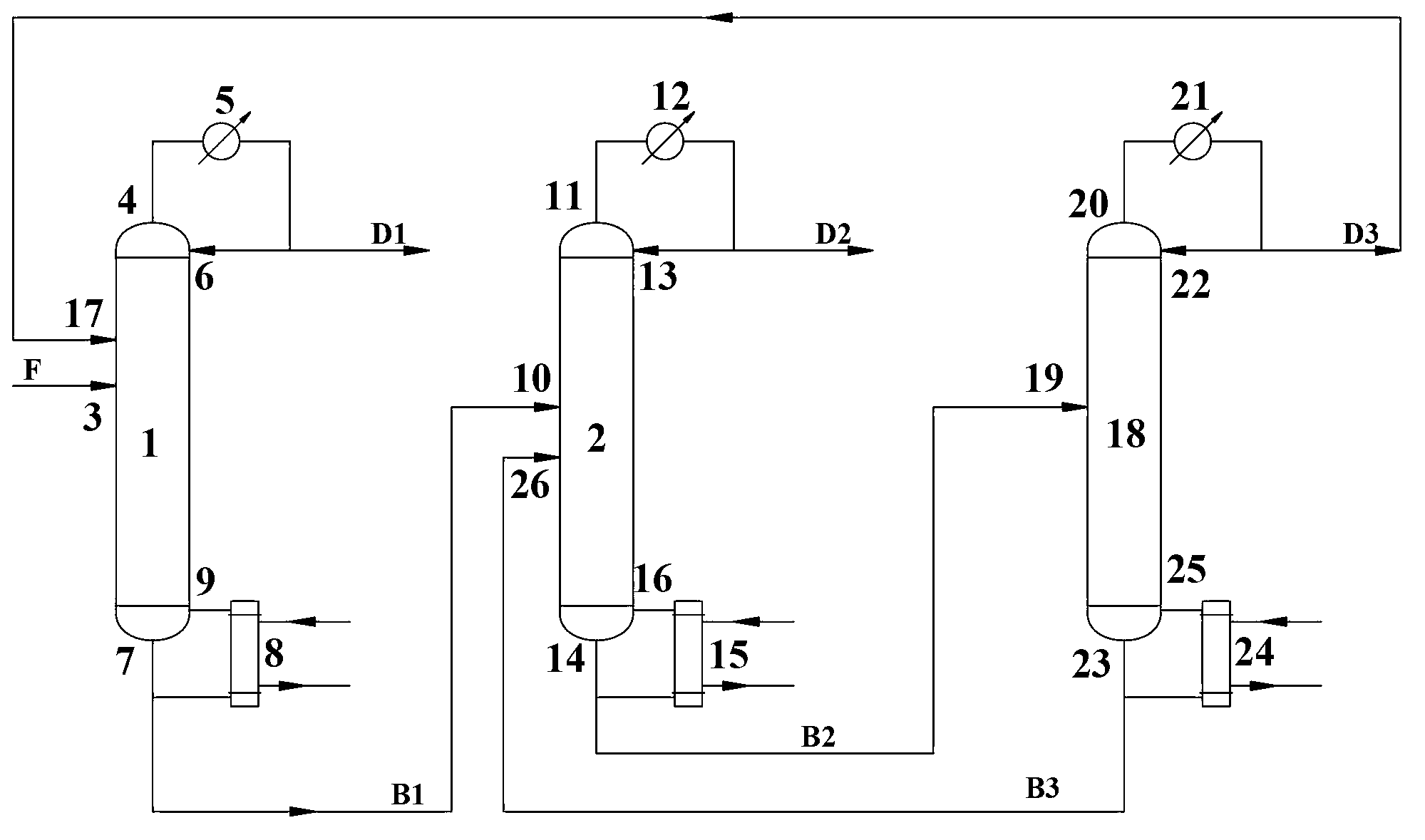

[0058] use as figure 2 The three-tower process flow shown as an example:

[0059] The raw material F is a cyclohexanone / phenol solution with a phenol content of 70%wt, and its flow rate is 3kg / h. F is sent into the first low-pressure rectification tower 1 that operating pressure is 3kPa simultaneously with the D3 solvent stream stream of 5kg / h with recirculation flow rate and separates, and the cyclohexanone product D1 that the tower top obtains purity is 99.9wt%, and tower kettle is extracted The phenol / solvent azeotrope B1 and stream B1 under this pressure will be sent to the subsequent double-column pressure swing rectification system to realize the recovery of phenol product and solvent.

[0060] In this follow-up double-tower pressure swing rectification system, B1 is first sent to the high-pressure rectification tower 2 with an operating pressure of 180kPa for separation. Under this pressure, the phenol content in the phenol / solvent azeotrope is significantly higher th...

example 3

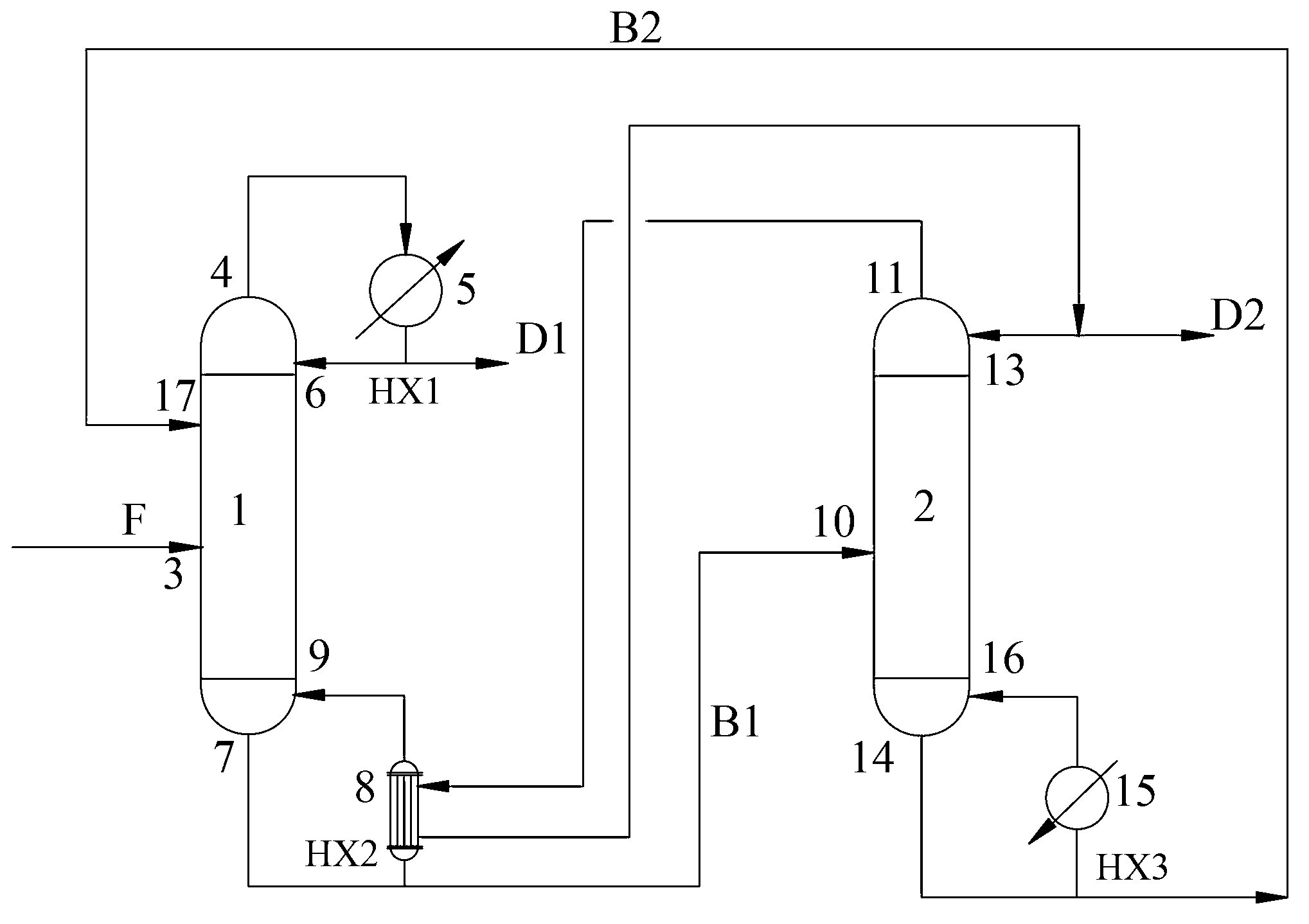

[0064] Such as image 3 As shown, the thermal coupling technology can be implemented in the double-tower process, and the heat released by the condensation of steam at the top of the high-pressure tower can be used to provide heat for the bottom of the low-pressure tower to achieve energy saving and reduce equipment investment.

[0065] Among the figure, the first low-pressure rectification tower 1 is a low-pressure tower whose operating pressure is 3kPa, and the cyclohexanone product whose purity can reach 99.9wt% is extracted from the top of the tower, and the tower still is phenol and solvent azeotrope under this pressure, and the azeotrope The boiled matter is sent into the high-pressure rectification tower 2 whose operating pressure is 260kPa for separation. The phenol product with a purity of up to 99.9wt% is extracted from the top of the high-pressure rectification tower. Under this separation condition, the temperature of the steam at the top of the high-pressure rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com