Method for manufacturing bricks by using household garbage

A technology for domestic waste and garbage, applied in the combustion method, application, household appliances, etc., can solve the problems of destroying the landscape, affecting the ecology, encroaching on the land, etc., and achieving the effect of reducing production time, saving energy, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

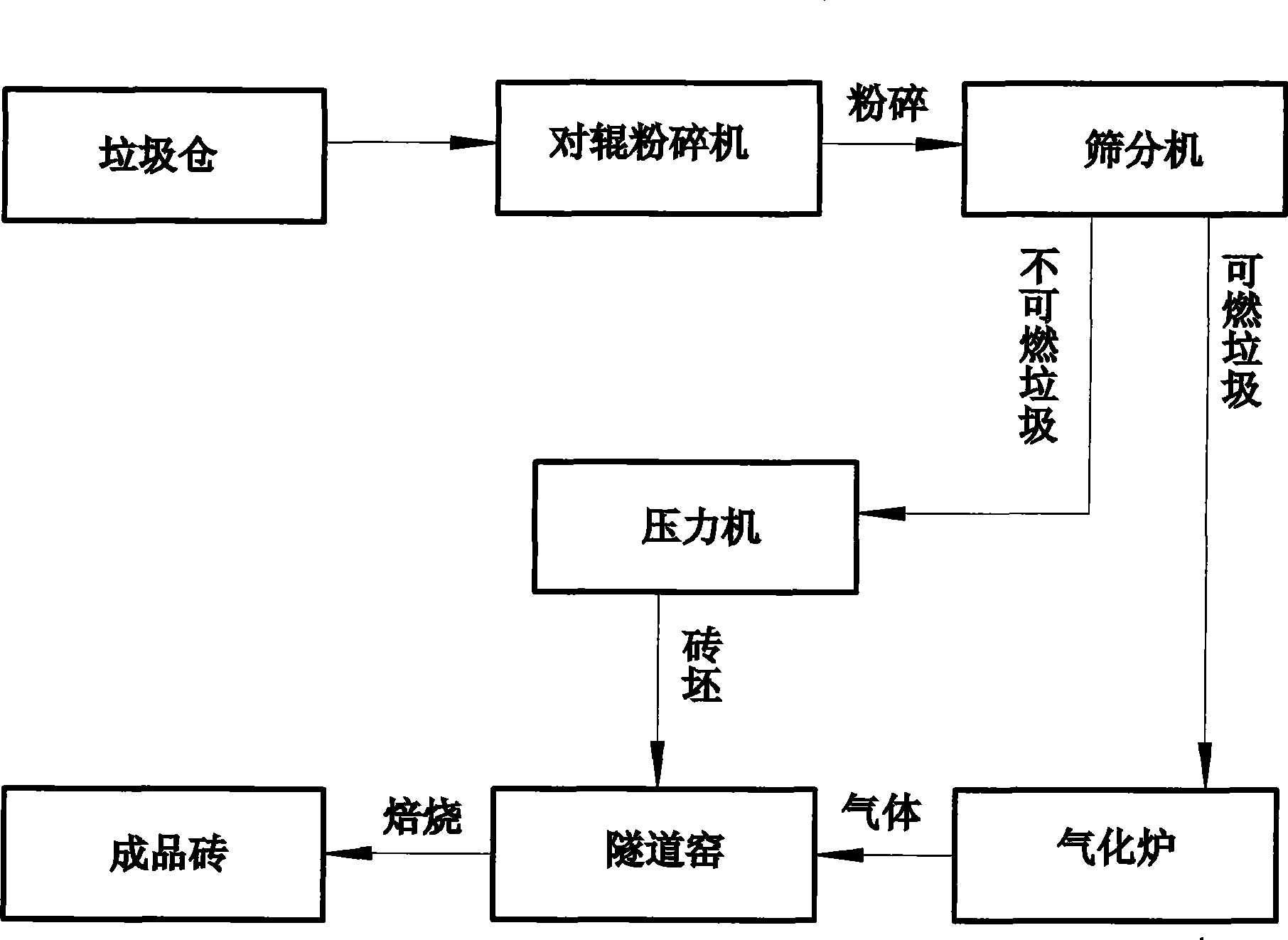

[0022] Embodiment one: the method for making brick with household garbage

[0023] Squeeze the domestic waste through a double-roller pulverizer, and sieve it with a coarse sieve with an aperture of 1cm. After screening, the waste is divided into combustible waste and non-combustible waste;

[0024] Weigh 40 parts of non-combustible garbage, 12 parts of coal gangue, and 20 parts of clay according to the proportion, crush them into particles below 1.5 cm, mix them, add 25% of the water in the mixture, mix them evenly, and dry them under a pressure of 9 to 10 MPa. After being pressed, it is made into bricks, and then enters the tunnel kiln for preheating, and gradually raises the temperature to 800°C; the combustible garbage is incinerated and gasified in the gasification furnace, and the gas generated by gasification is passed into the tunnel kiln roasting area as fuel, and is heated at 1050 The adobe is fired at ℃ for 7-8 hours, and then cooled naturally out of the kiln.

[0...

Embodiment 2

[0026] Embodiment two: the method for making brick with household refuse

[0027] Squeeze the domestic garbage through a double roller crusher, and then sieve it with a coarse sieve with an aperture of 1 cm. After screening, the garbage is divided into combustible garbage and non-combustible garbage; 70 parts of non-combustible garbage, 20 parts of coal gangue, and 40 parts of clay Parts, weighed according to the proportion, crushed into particles below 1.5cm, mixed, then added 30% water of the mixture, mixed evenly, dry pressed under 10-12MPa pressure to make bricks, and then entered the tunnel kiln for preheating, and gradually raised the temperature to 900°C; incinerate and gasify the combustible waste in a gasification furnace, and the gas produced by gasification is passed into the tunnel kiln roasting area as fuel, and the bricks are fired at 1100°C for 8 hours, and then cooled naturally to leave the kiln.

Embodiment 3

[0028] Embodiment three: the method for making brick with household garbage

[0029] Squeeze the household garbage through a double-roller pulverizer, sieve it with a coarse sieve with an aperture of 1cm, and divide it into combustible garbage and incombustible garbage after sieving; divide 42 parts of non-combustible garbage, 18 parts of coal gangue, and 22 parts of clay , weighed according to the proportion, crushed into particles below 1.5cm, mixed, then added 22% water of the mixture, mixed evenly, and dry pressed under 11MPa pressure to make bricks; combustible garbage was incinerated and gasified in a gasifier, and the The gas produced by gasification is passed into the tunnel kiln as gas fuel, and the adobe is fired at 1070°C for 6 hours, and then cooled naturally to leave the kiln.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com