Large-output low-temperature circulating grain drying equipment

A grain drying and high-yield technology, which is applied in the direction of drying and preserving seeds, can solve the problems of restricting the development of large-yield circulating grain dryers, increasing or expanding the body, and low work efficiency, so as to improve dusty, compact structure, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

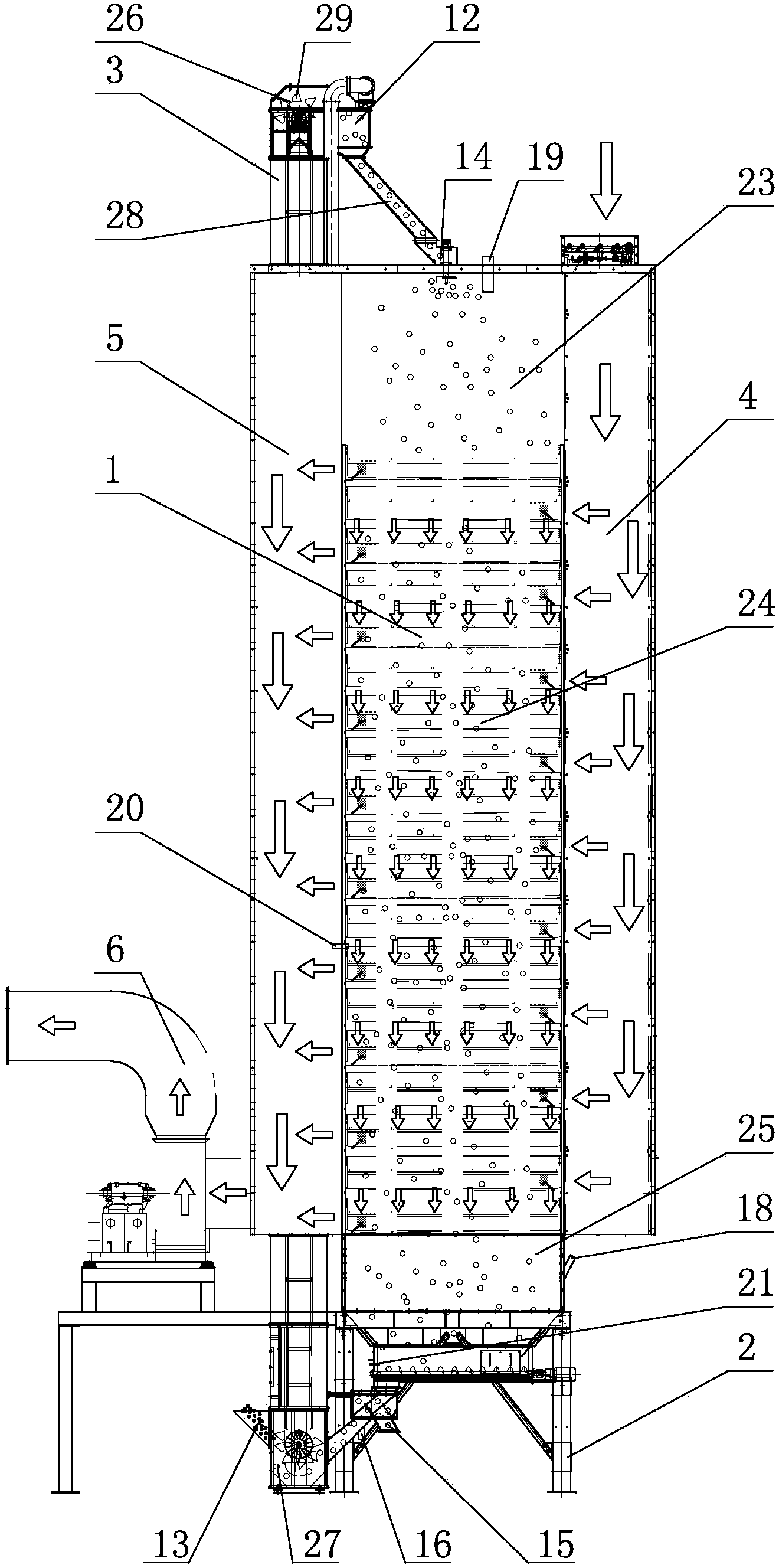

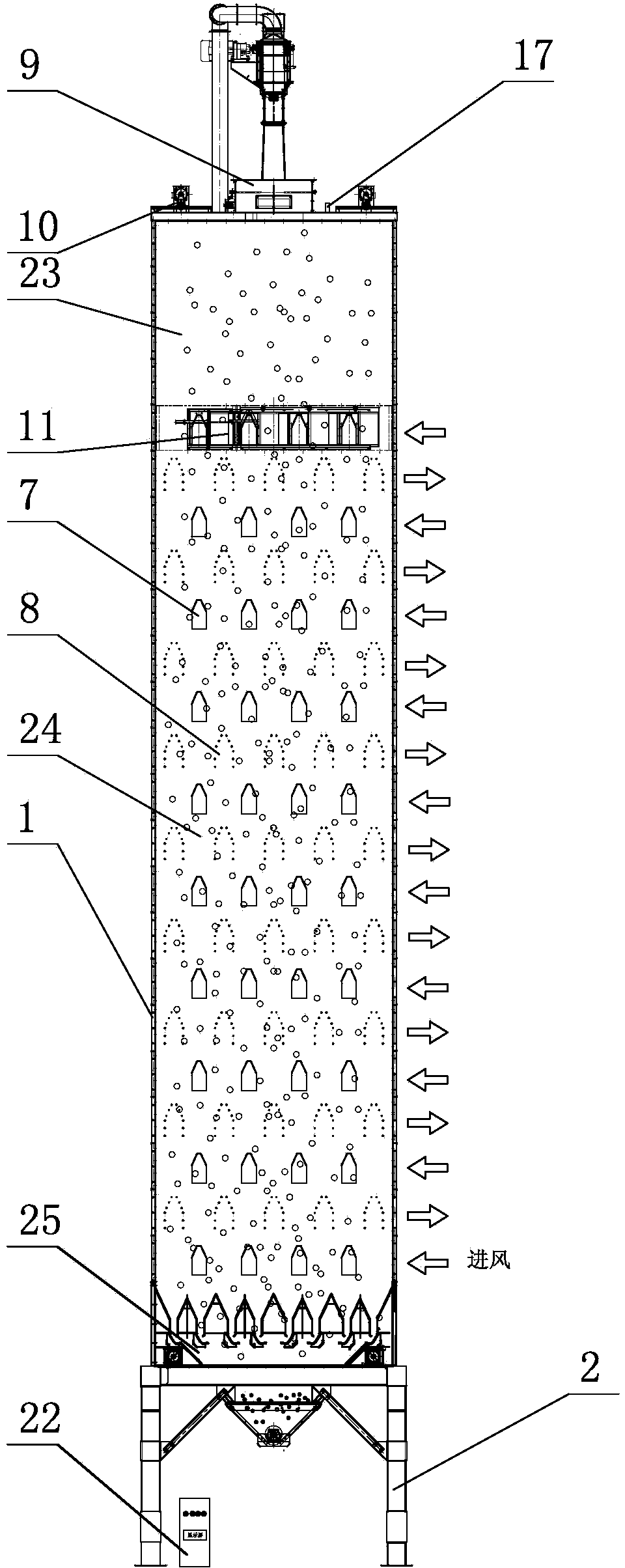

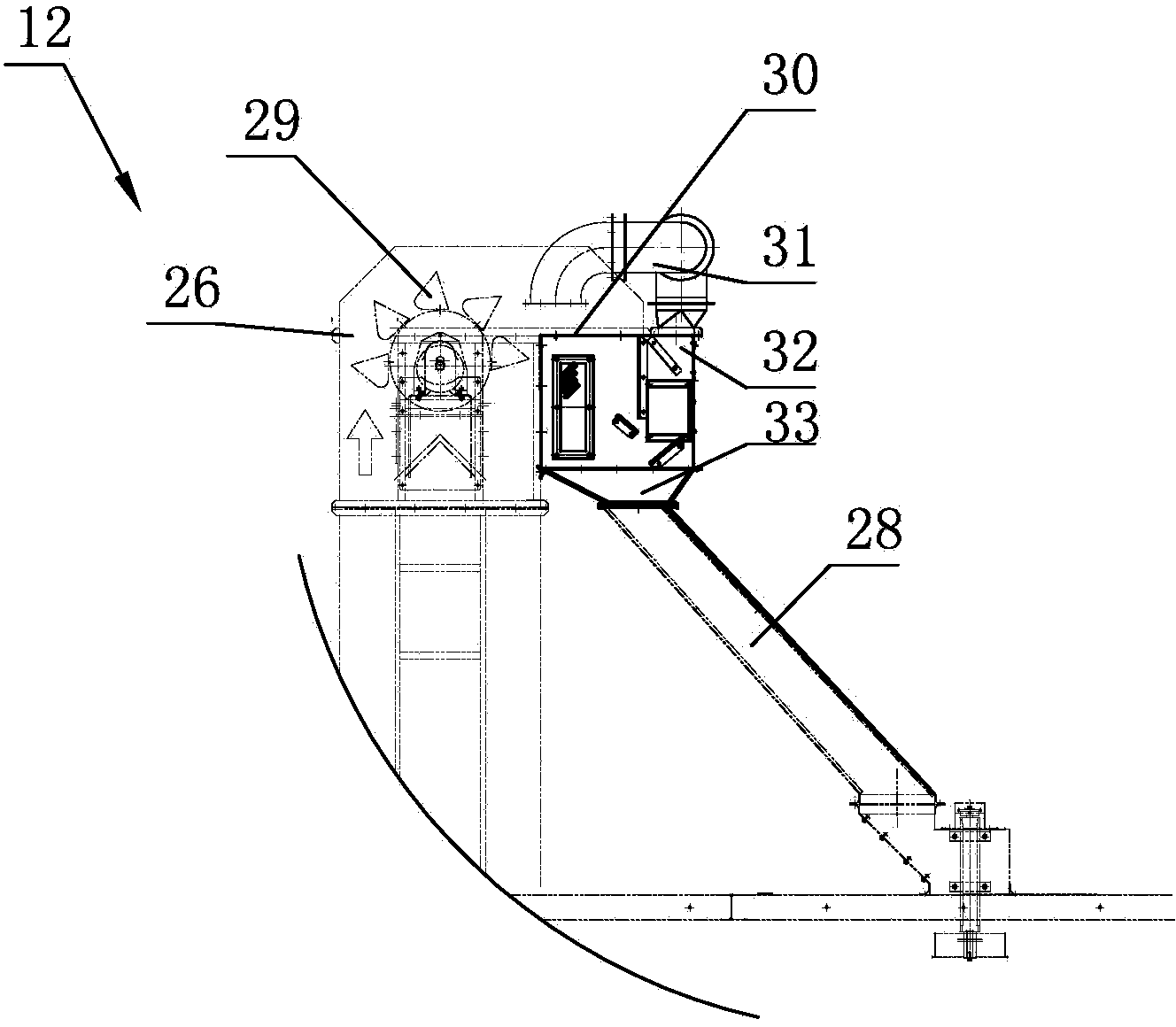

[0041] like figure 1 and figure 2As shown, the large-capacity low-temperature circulation grain drying equipment of this embodiment includes a lower frame 2 on which a drier body 1 is installed. The inside of the drier body 1 is divided into three parts from top to bottom, and the upper part is a storage Retention section 23, the middle part is dry storage section 24, the lower part is grain discharge section 25, and grain discharge section 25 is located on the lower platform 2; hot air passage 4 and exhaust passage 5 are respectively arranged on both sides of the dryer body 1 , the inside of the exhaust duct 5 is equipped with a hoist 3, the hoist 3 runs through the entire exhaust duct 5, the hoist head 26 is installed on the top of the exhaust duct 5, the hoist tail 27 is installed on the bottom of the exhaust duct 5, and A feed hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com