Process for recycling waste mineral oil without hazardous material emission

A waste mineral oil recovery and treatment technology, applied in hydrocarbon oil treatment products, gasification process, petroleum industry, etc., can solve the problems of low recovery rate of waste engine oil, pollution, human hazards, etc., achieve thermal energy recycling and benefit Effects on society and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

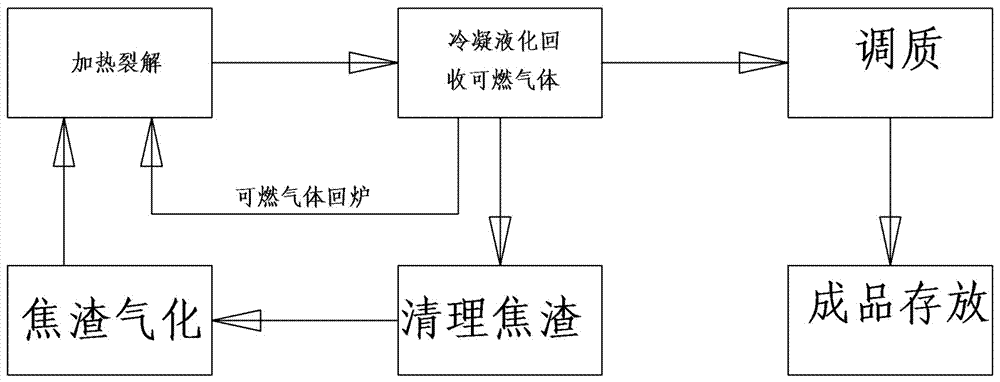

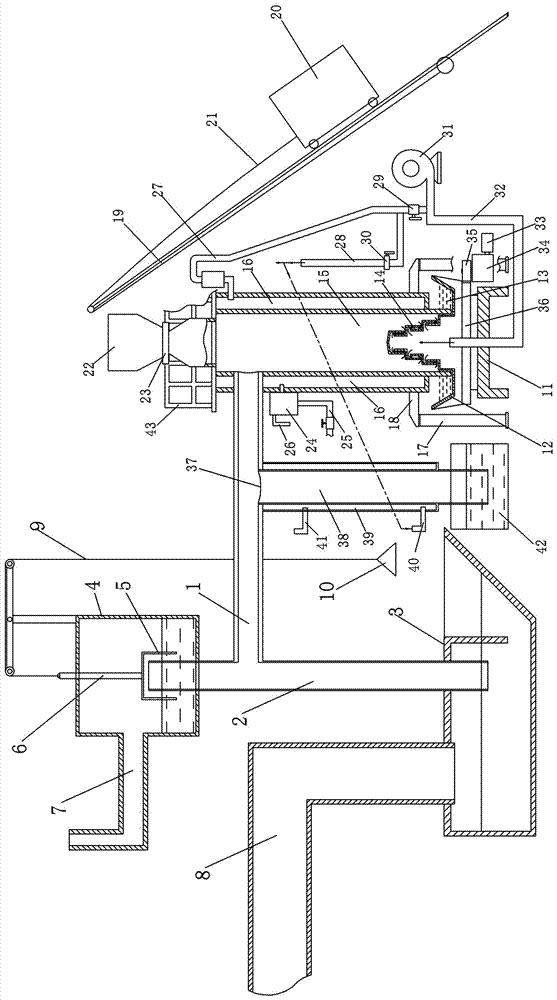

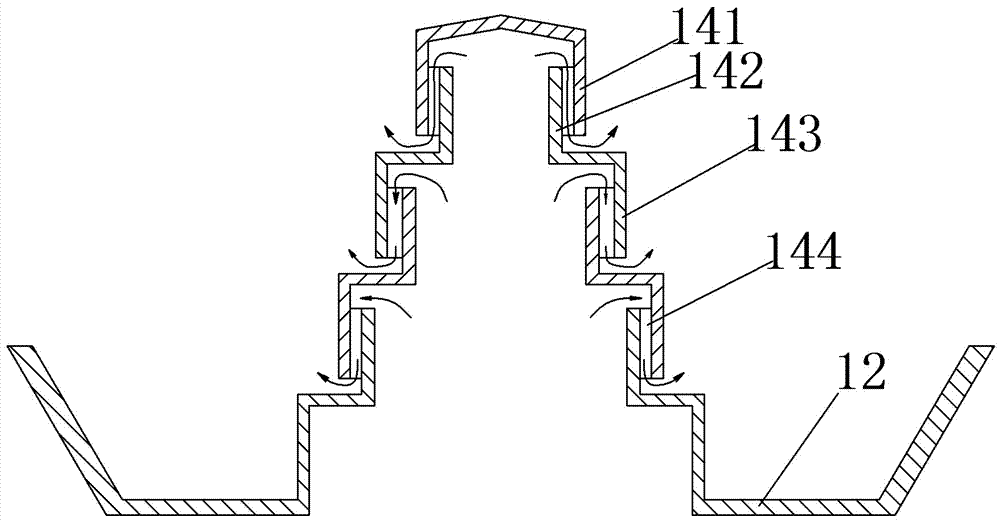

[0034] Embodiment one: see Figure 1-3 , a recycling process for waste mineral oil without hazardous discharge in the figure, comprising the following steps:

[0035] ①. Heating cracking

[0036] Add the liquid waste mineral oil into the reaction kettle, and heat the reaction kettle through a gas furnace to promote the cracking of the internal liquid waste mineral oil to obtain gaseous light diesel fraction and other combustible gases;

[0037] ②. Condensate and liquefy while recovering combustible gas

[0038] Introduce the gaseous light diesel oil fraction produced in step ① into the heat exchange equipment for condensation to form liquid light diesel oil, recover and collect other combustibles that have not been condensed into liquid, and introduce them into the gas furnace through pipelines to burn them as fuel ;

[0039] ③. Tempering

[0040] The liquid light diesel oil in the step ② is carried out conditioning and tempering by adding the reagent for conditioning;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com