Iron-based amorphous alloy powder for degradation of dye waste liquid and preparation method and application of iron-based amorphous alloy powder

A technology of iron-based amorphous alloy and dye waste liquid, applied in chemical instruments and methods, water pollutants, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of complex preparation process and degradation rate of dye degradation catalysts Slow, low degradation rate and other problems, to achieve the effect of fast catalytic degradation reaction rate, improved degradation rate, and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

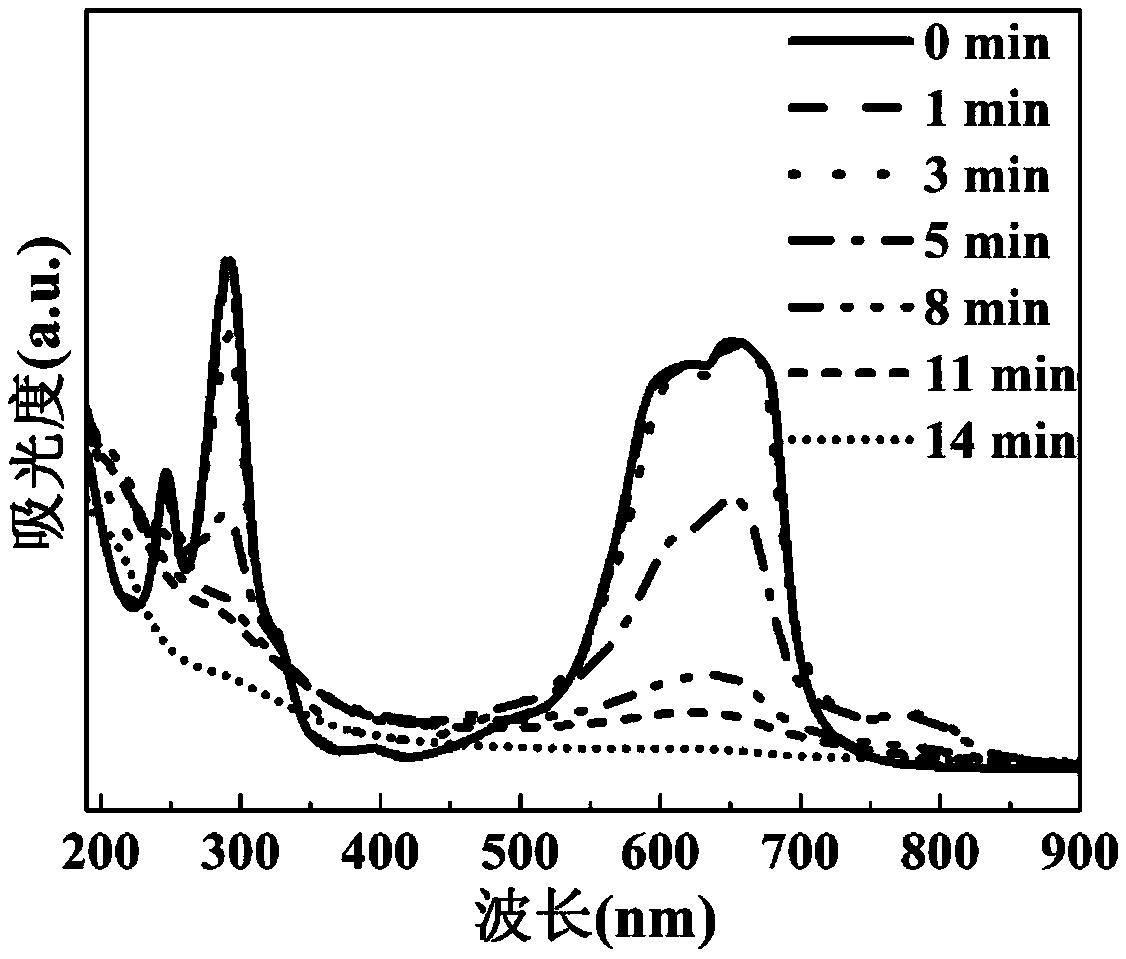

[0045] This embodiment studies the industrial Fe after ultrasonic treatment 78 Si 9 B 13 Ability of iron-based amorphous powders to degrade methylene blue.

[0046] Step 1: The industrial pure Fe, Si, B elements according to the molecular formula Fe 78 Si 9 B 13 Prepare raw materials, use electric arc furnace to melt into a uniform master alloy, remelt the melted master alloy into alloy liquid and spray cast it on the surface of a high-speed rotating copper roller with a speed of 30m / s to obtain an iron-based amorphous alloy with a uniform composition Strips; put the prepared industrial amorphous strips into a ball mill (air atmosphere) for 24 hours at high speed to obtain Fe with a particle size distribution of 1-50 μm 78 Si 9 B 13 Iron-based amorphous alloy powder for industrial use.

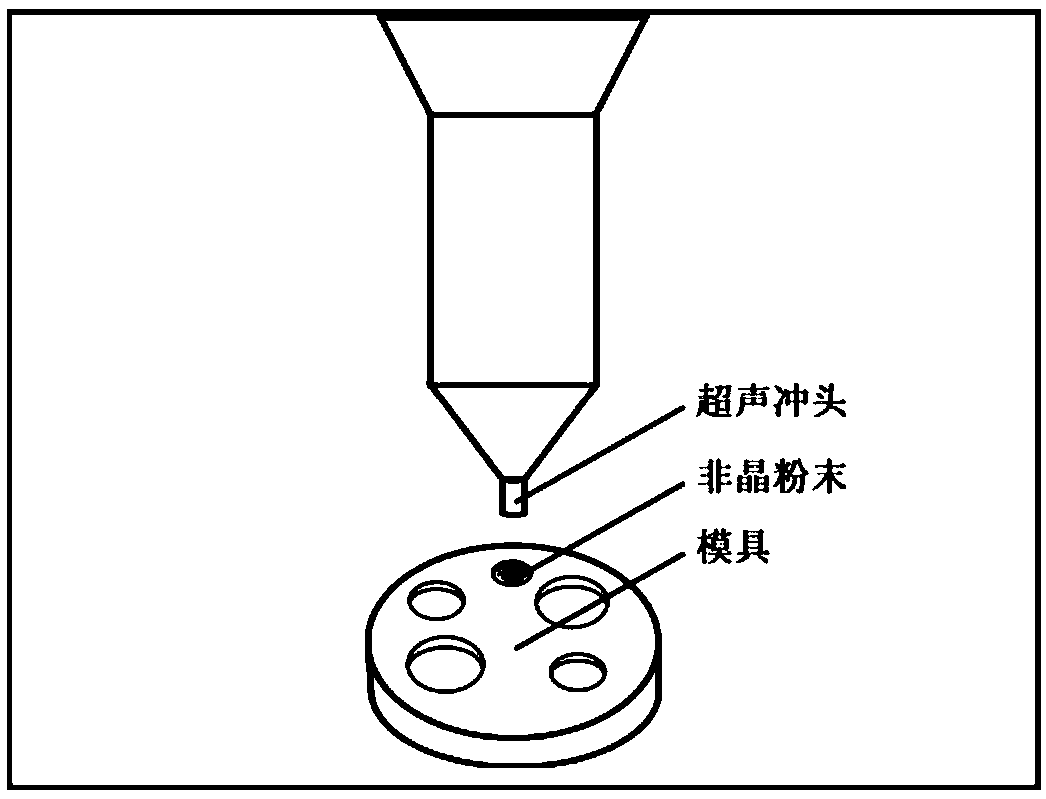

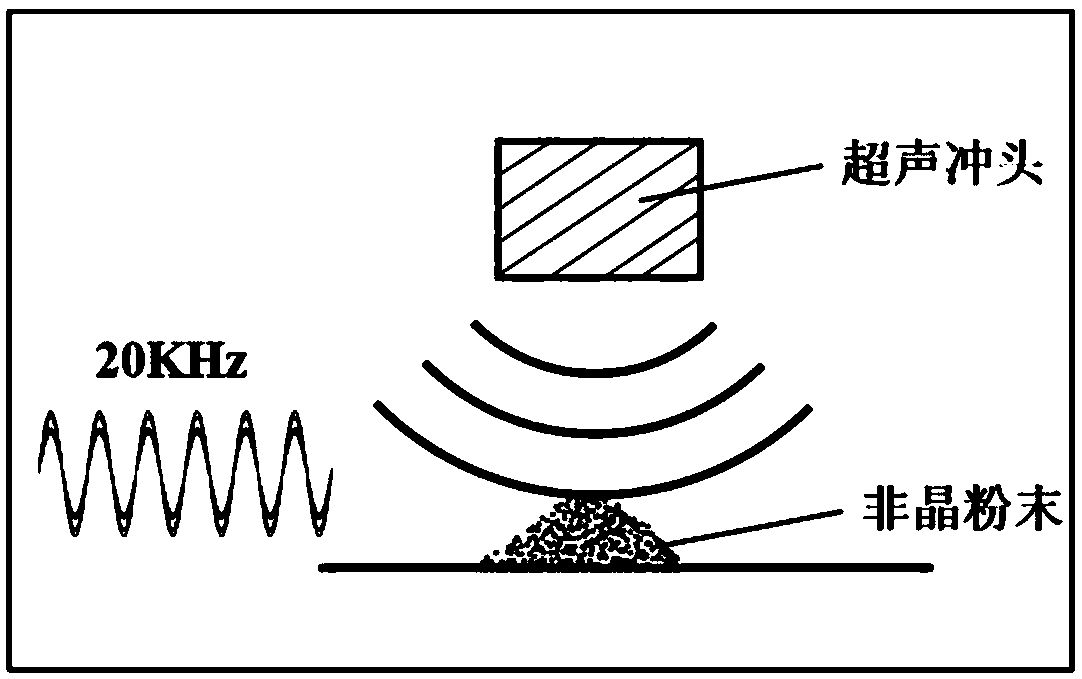

[0047] Step 2: Incorporate industrial Fe 78 Si 9 B 13 The amorphous powder is ultrasonically treated under ultrasonic trigger pressure of 100N, amplitude of 100%, working pressure o...

Embodiment 2

[0061] This embodiment has studied solution pH value to industrial Fe 78 Si 9 B 13 The effect of amorphous powders on the ability to catalyze the degradation of methylene blue.

[0062] Step 1: The industrial powder is subjected to ultrasonic treatment under ultrasonic energy of 500KPa and 750J.

[0063] Step 2: Add 250mL of methylene blue solution with a concentration of 100mg / L to a beaker with a capacity of 500mL, put the beaker in a constant temperature water bath with a temperature of 25°C to keep warm, add hydrogen peroxide after the solution temperature is stable, adjust the concentration of hydrogen peroxide to 1mM, adjust Solution pH to 2,3,4,5,9.

[0064] Step 3: Put the iron-based amorphous powder prepared in step 1 into a beaker after weighing according to the amount of 0.4 g / L of the methylene blue solution. The solution is mechanically stirred by a mechanical stirring device, so that the industrial Fe 78 Si 9 B 13 The amorphous powder is in uniform contact...

Embodiment 3

[0071] This embodiment has explored the industrial Fe in the solution 78 Si 9 B 13 Effect of the amount of amorphous powder on the ability of catalytic degradation of methylene blue.

[0072] Step 1: The industrial powder is subjected to ultrasonic treatment under ultrasonic energy of 500KPa and 750J.

[0073] Step 2: Add 250mL of methylene blue solution with a concentration of 100mg / L to a beaker with a capacity of 500mL, put the beaker in a constant temperature water bath with a temperature of 25°C to keep warm, add hydrogen peroxide after the solution temperature is stable, adjust the concentration of hydrogen peroxide to 1mM, adjust The pH of the solution is 3.

[0074]Step 3: Weigh the iron-based amorphous powder prepared in step 1 according to the amount of 0.1g / L, 0.2g / L, 0.3g / L, 0.4g / L, and 0.5g / L according to the amount of methylene blue solution, and put it into in the beaker. The solution is mechanically stirred by a mechanical stirring device, so that the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com