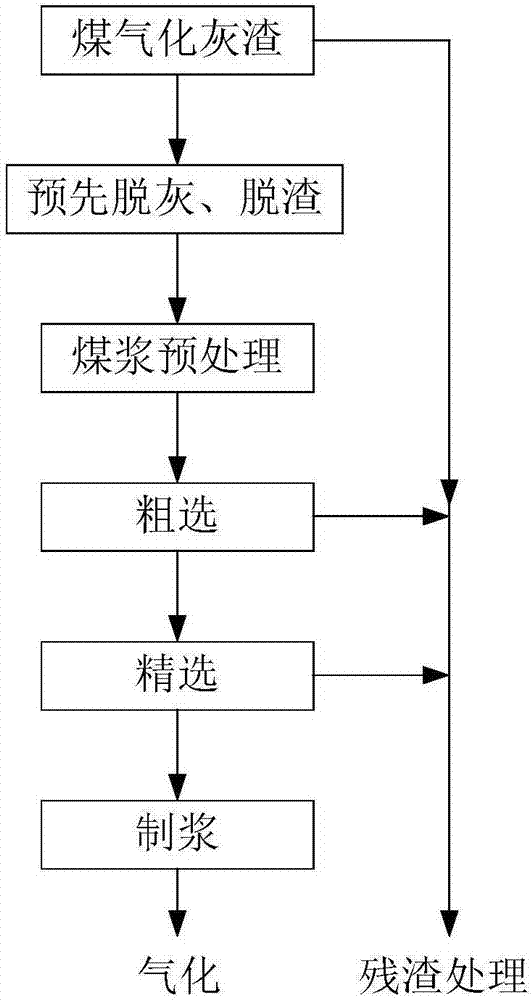

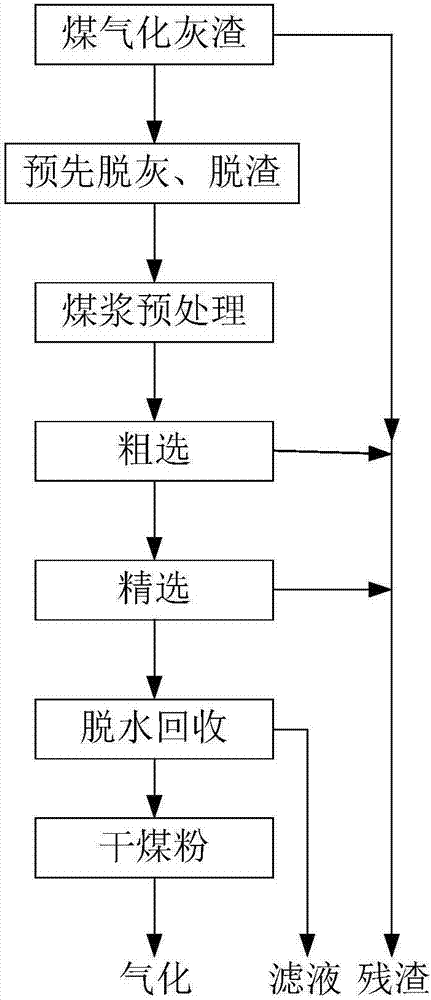

Process for recovering carbon from coal gasification ash residues

A coal gasification ash and carbon recovery technology, which is applied in the petroleum industry, solid separation, solid fuel, etc., can solve the problems of complex process, high cost, and low carbon recovery rate, and achieve the goal of avoiding environmental pollution and improving resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The first step is pre-deashing and deslagging

[0032] The coal gasification ash with a carbon content of 15% is made into ash and the water flows into the material deashing tank by itself, and part of the fine ash is removed by means of hydraulic classification. A frequency converter is used to control the flotation feeding pump, and through frequency conversion technology, the amount of deashing can be flexibly adjusted online depending on the coal quality. The equipment is a reinforced concrete structure, which has two functions of flotation feeding buffer, deashing and slag removal. In the flotation feeding deashing tank, deashing is carried out by means of hydraulic classification, and the fine ash with an ash content of 55% is removed in advance, and the removal rate can reach 35%.

[0033] The second step coal slurry pretreatment

[0034] Input the coal slurry that has been pre-delimed and deslagged into the coal slurry preprocessor, add flotation agent to the ...

Embodiment 2

[0040] The coal gasification ash with a carbon content of 15% is subjected to deashing, slag removal and coal slurry pretreatment, the steps of which are the same as in Example 1, and will not be further elaborated here.

[0041] The third and fourth steps of flotation (rough selection first, then fine selection)

[0042] In this step, selectors with different numbers of chambers are selected for roughing and fine selection respectively. During the flotation process, in order to ensure that the amount of air per unit area is controlled at 0.5m 3 / m 2 / min. Carry out flotation then, its step is:

[0043] a. Rough selection

[0044] The pretreated coal slurry first enters the rough selection flotation machine, and then undergoes rough selection. The unit area of the rough selection jet flotation machine is 0.5m 3 / m 2 / min, the roughing time is 12 minutes, and the processing capacity per unit volume is 4m 3 / m 3 / h, sort out the rough coal with ash content of 10% and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com