Iron tailing sand doped high-strength concrete, and preparation and applications thereof

A high-strength iron tailings sand technology, applied in the field of concrete, can solve the problems of low utilization rate and large tailings stockpile, and achieve the effects of improving strength, protecting the ecological environment, and saving sand and gravel resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention proposes high-strength concrete mixed with iron tailings and its preparation and application. The concrete strength grade is above C80, and the main raw material is iron tailings, so as to solve the problem of large tailings stock in my country and low utilization value, which affects cities and surrounding areas. Environmental issues.

[0025] The invention proposes a high-strength concrete mixed with iron tailings and its preparation, which can not only alleviate the problems of large stock of tailings and low utilization value in my country, but also adjust the structure of the concrete itself by adding iron tailings to the concrete , improve the compressive and anti-seepage capacity of concrete, and reduce the excavation of river sand.

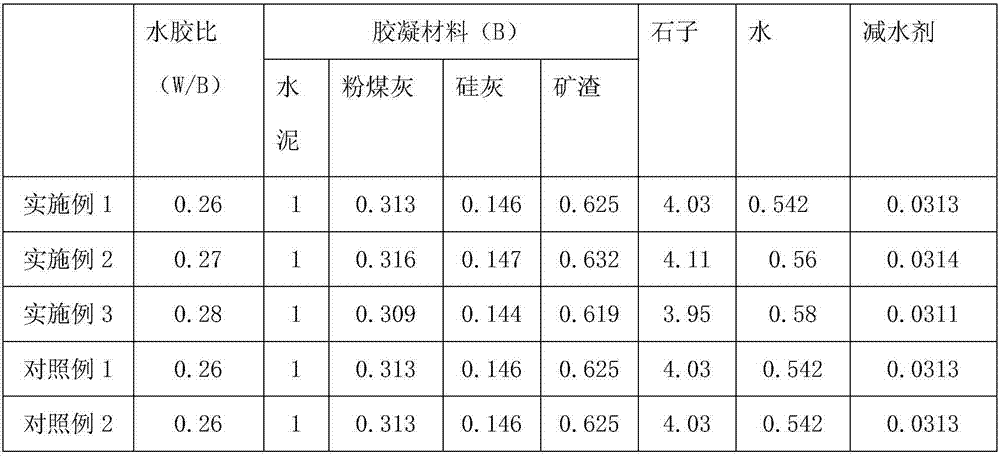

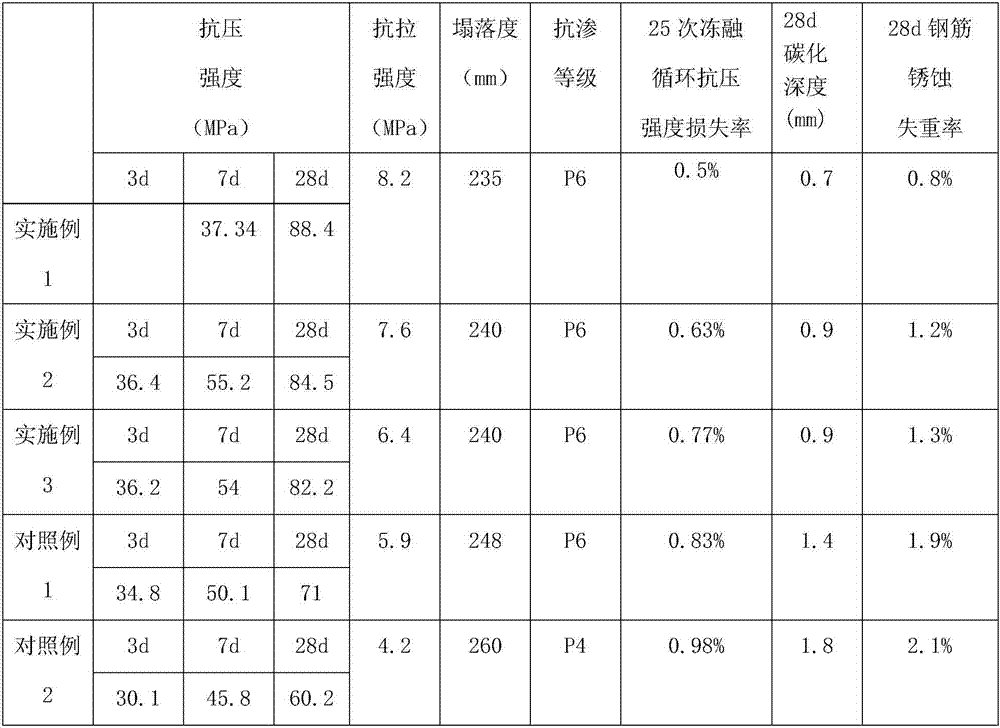

[0026] A kind of high-strength concrete mixed with iron tailings, the consumption of each component in the described concrete per cubic meter is as follows:

[0027] 285kg-291kg of cement (the cement is ordinary Portlan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com