Preparation method of memristor

A technology of memristive device and separation method, which is applied in the field of memory manufacturing, can solve problems such as the negative impact of semiconductor materials, and achieve the effects of low manufacturing cost, long cycle life and high switching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings, wherein:

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

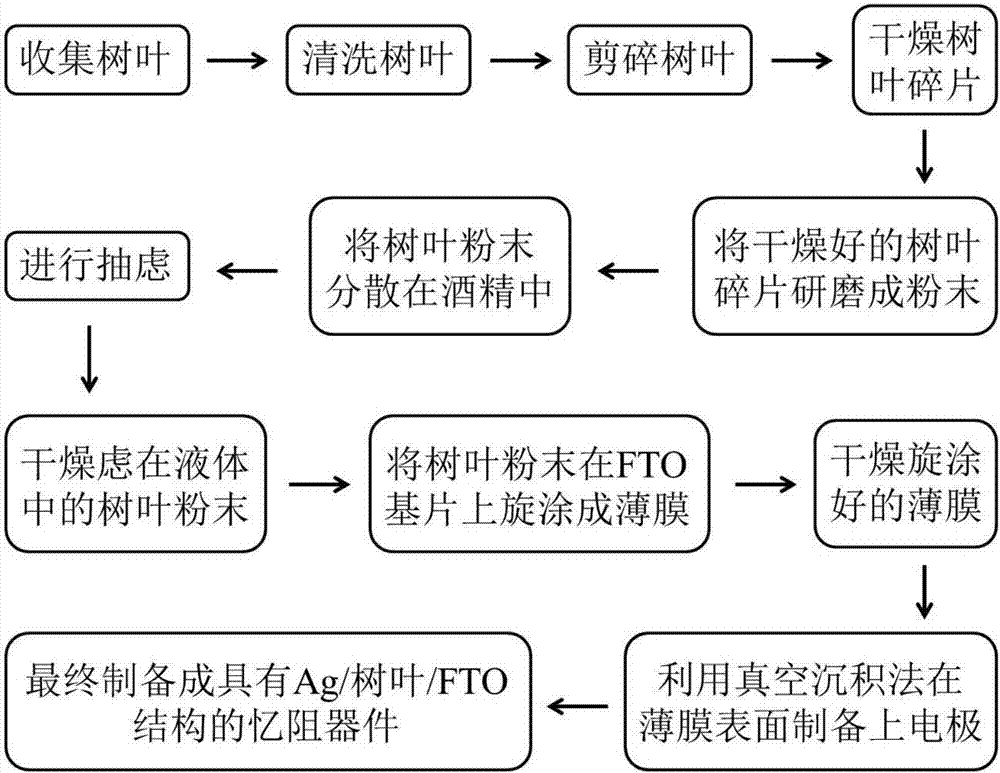

[0025] figure 1 It is a flow chart of extracting ultrafine leaf powder by separation method, and a flow chart of preparing a silver / leaf / FTO memristive device on a conductive substrate. Such as figure 1 As shown, the preparation method of the silver / leaf / FTO memristive device of the present embodiment comprises the following steps:

[0026] Step 1, collecting enough dry leaves;

[0027] Step 2. Wash the leaves collected in step 1 with alcohol and deionized water several times in turn, then cut them into pieces with scissors, put them in a beaker, and then place them in a drying oven at 60°C Dry for more than a week, dry enough to be g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com