Explosive welding method for zirconium-steel-zirconium three layer pipe

A technology of explosive welding and three-layer pipe, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of economic decline and high price of zirconium metal, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

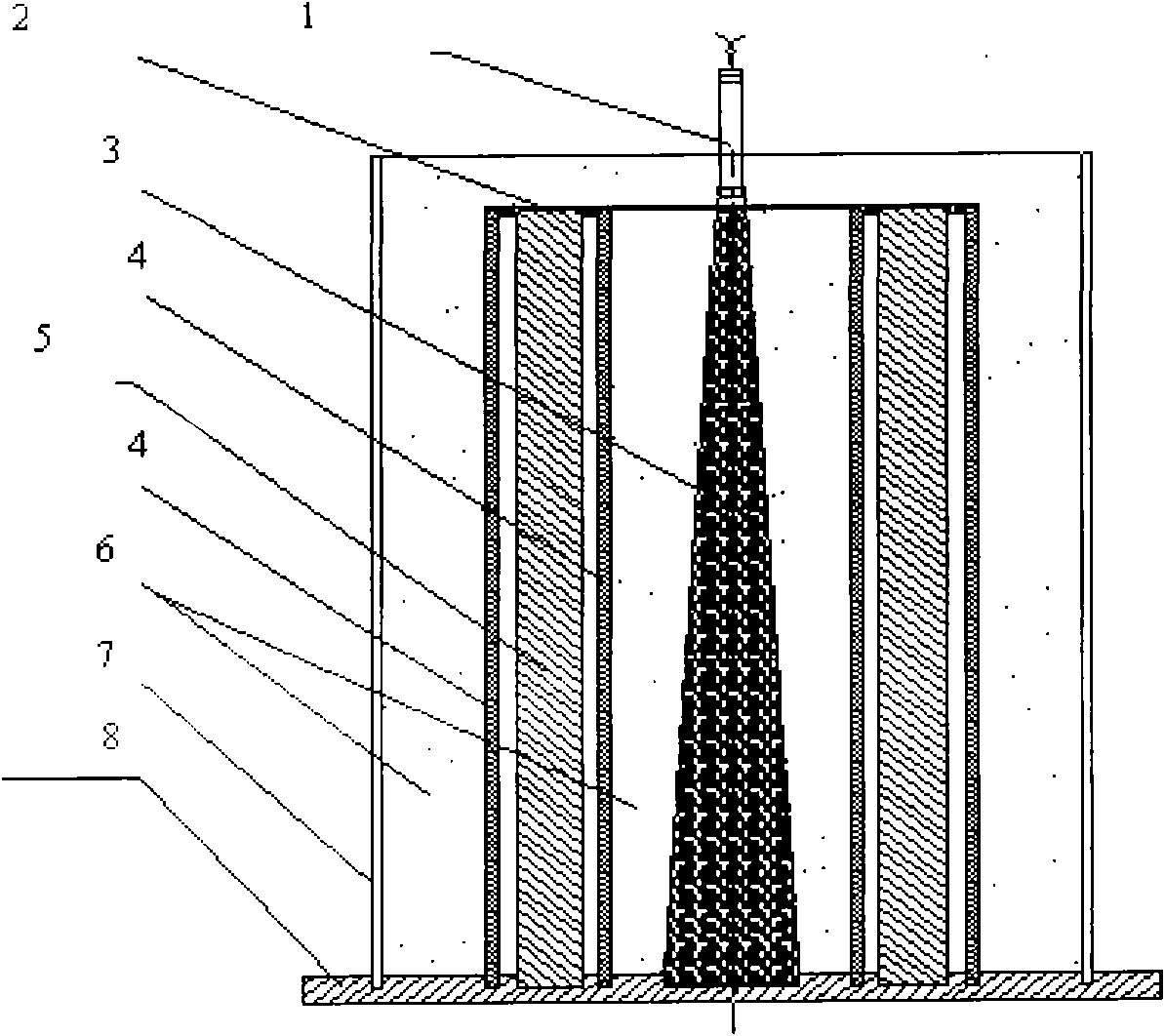

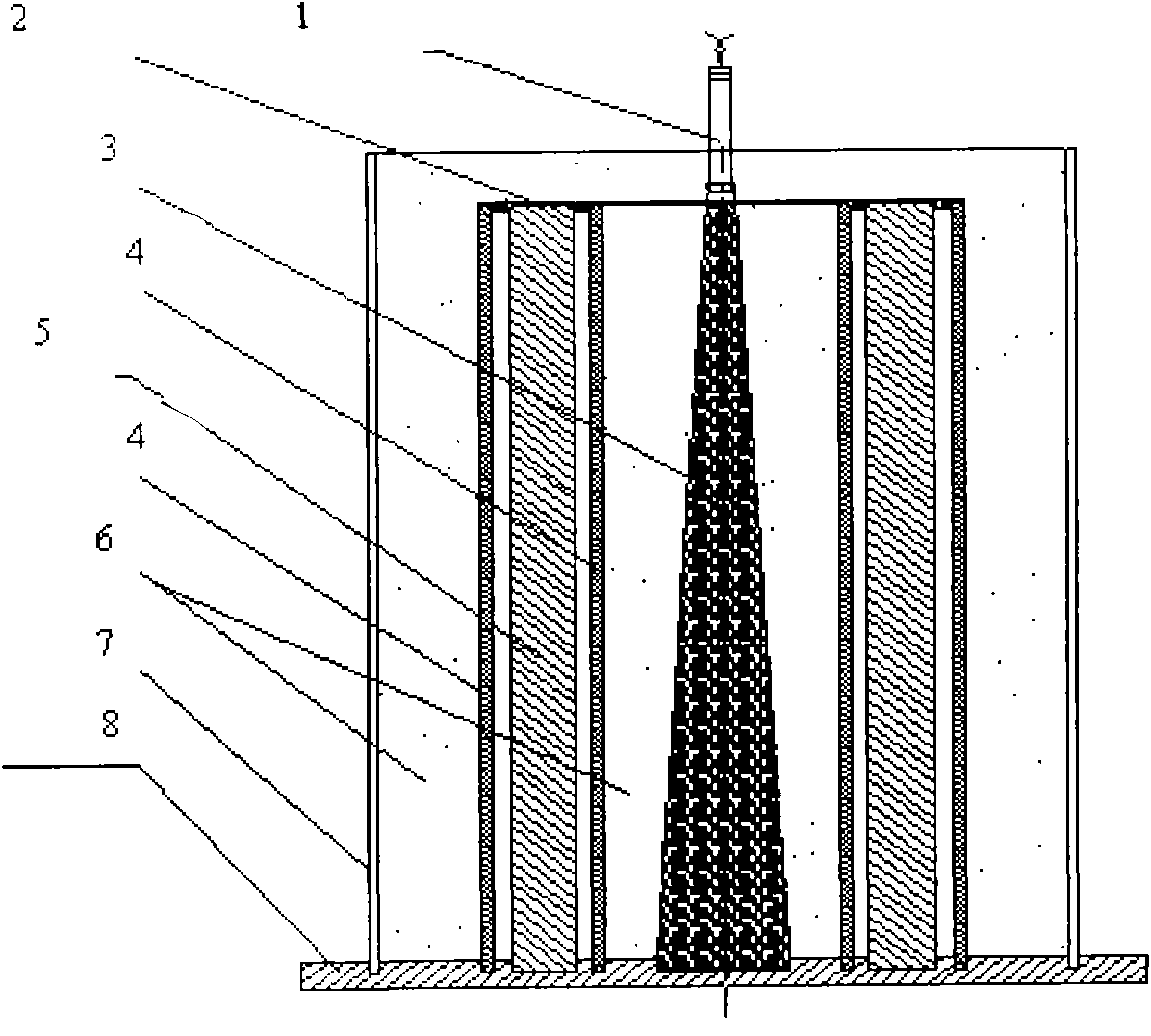

[0017] Embodiments of the present invention will be specifically described below. For a typical explosive three-layer composite tube of zirconium tube and steel tube, the diameter of the outer zirconium tube is 50-500mm and the thickness is 1-8mm, and the diameter of the steel tube is 55-500mm and the thickness is 8-200mm. The diameter of the outer zirconium tube is especially better at 100-500 mm, and the inner diameter of the steel tube is 5 mm larger than the outer diameter of the inner zirconium tube, and the inner diameter of the outer zirconium tube is 5 mm larger than the outer diameter of the steel tube; the inner diameter of the inner zirconium tube is larger than the maximum diameter of the buffer cone by 10 mm. The cone angle of the decompression buffer cone is in the range of 8-30 degrees, especially in the range of 12-20 degrees.

[0018] Firstly, the base tube is straightened, so that the straightness of the steel tube is less than 2mm / m; and the whole tube is ≤5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com