Preparation method of large-area all-joint-rate zirconium/titanium/steel explosive clad plate

An explosive composite board and full lamination technology, which is applied in the direction of welding/welding/cutting objects, manufacturing tools, welding equipment, etc., can solve the problems of low elongation, high price, unfavorable promotion and application of zirconium steel composite board equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

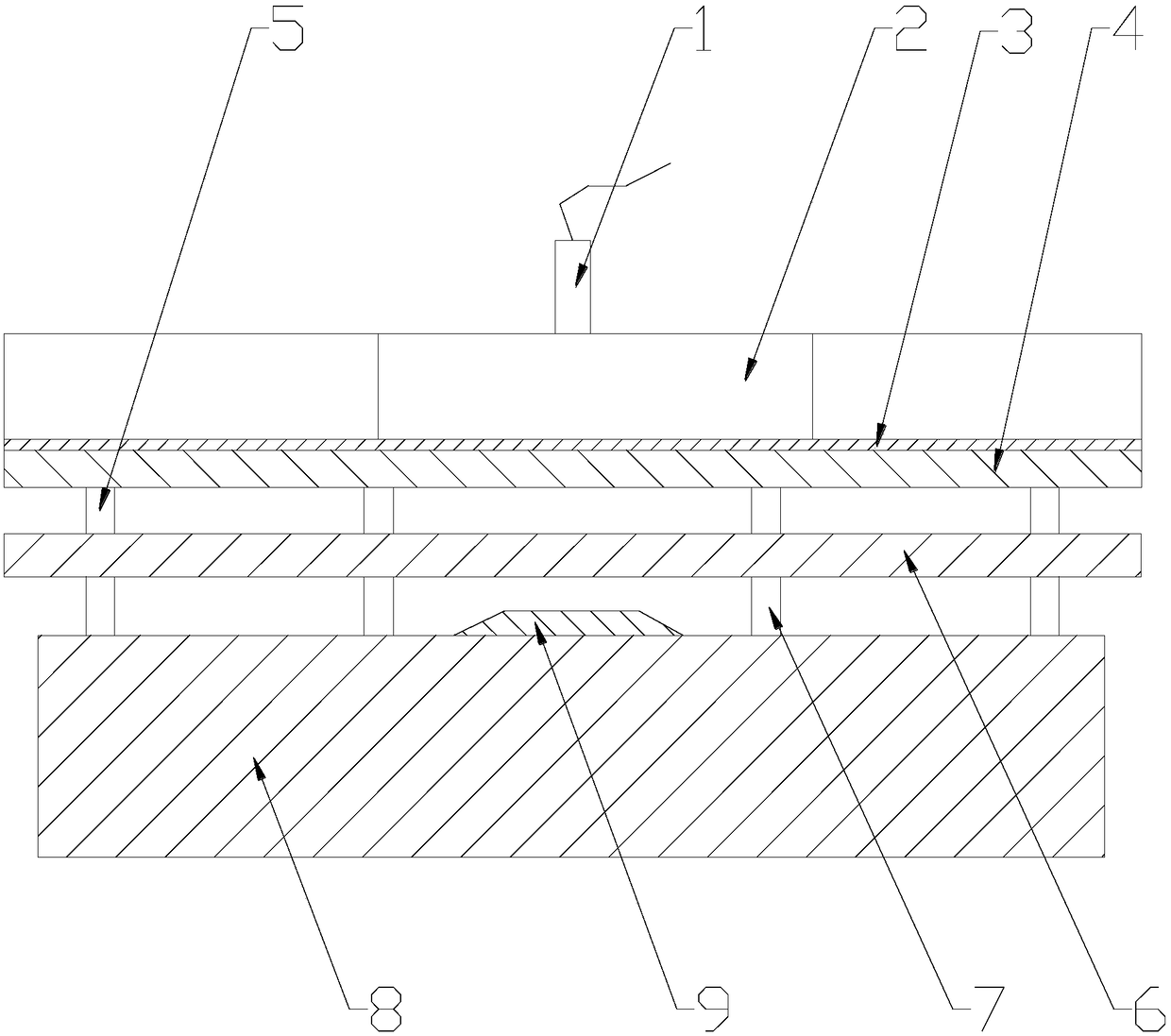

[0022] A method for preparing a large-area full-fit rate zirconium / titanium / steel explosive composite plate, comprising the following steps:

[0023] 1. If figure 1 As shown, the detonation point is first selected, and the explosive compounding of the transition layer 9 located at the detonation point is completed: that is, a transition layer 9 is formed by explosive compounding at the selected detonation point position with a titanium layer with a thickness of 2 mm and a diameter of 300 mm. After the transition layer is compounded, use a special grinder to grind away the unbonded titanium layer at the position of the detonation point, and grind and smoothly transition to the steel plate layer (substrate 8) around the bonded titanium layer.

[0024] 2. Then perform an explosive composite zirconium-titanium layer. When installing on site, place the zirconium plate 4 on the top as the first layer, place the titanium plate 6 on the second layer as the intermediate transition laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com