Explosive cladding welding method for titanium-steel composite board soldering joint

A technology of explosive cladding and welding methods, which is applied in the direction of welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problem that the weld seam of titanium-steel composite plate cannot be penetrated, and achieve the smooth surface of the weld seam, The effect of simple method and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

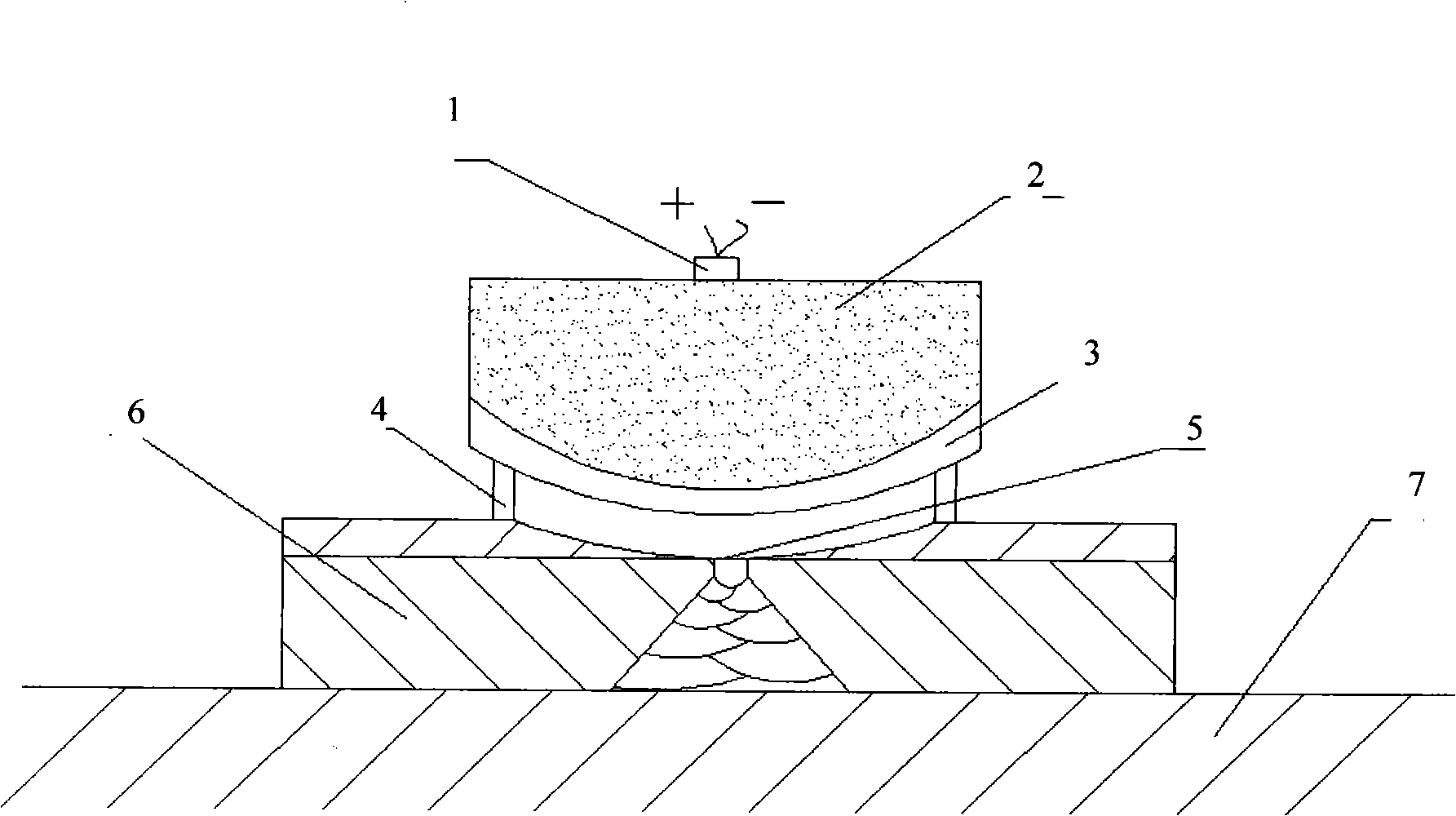

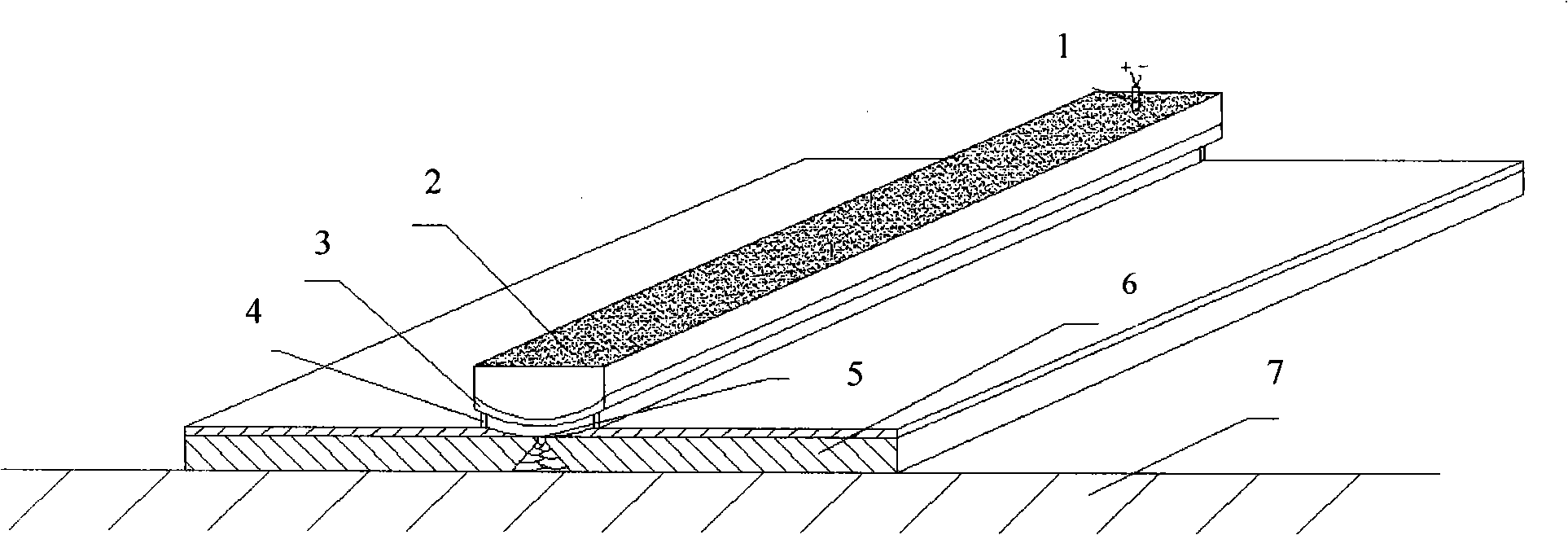

Embodiment 1

[0021] Two titanium-steel clad plates (the material combination is TA2 / 16MnR, the size is (6+34)×1500×3000mm) are welded together, and the weld length is 3000mm. The size of the arc-shaped titanium plate TA2 is 6×120×3100mm, the height of the support is 8mm, ammonium nitrate explosive is used, and it is directly placed on the upper surface of the arc-shaped titanium plate TA2, and the charge per unit area is 3.4g / cm 2 , use the No. 8 industrial electric detonator to detonate through the black wire explosive charge at the end, so that the titanium layer and the steel layer are clad into one. After ultrasonic testing, the composite rate of the entire weld is 100%. Sampling was carried out to test the bonding strength. The interface shear strength was ≥312Mpa, which was higher than the requirement of ≥196Mpa stipulated in the GB / T 8547-2006 "Titanium-Steel Composite Plate" standard. The interface was firmly bonded and a fully welded titanium-steel composite was obtained. plate c...

Embodiment 2

[0023] Two pieces of titanium-steel clad plates (the material combination is TA10 / Q235B, the size is (4+20)×2000×4000mm) are welded together, and the weld length is 4000mm. The size of the arc-shaped titanium plate TA10 is 4×100×4100mm, and the height of the support is 6mm. Ammonium nitrate explosives are used to directly lay on the upper surface of the arc-shaped titanium plate TA10, and the charge per unit area is 2.8g / cm 2 , use the No. 8 industrial electric detonator to detonate through the black wire explosive charge at the end, so that the titanium layer and the steel layer are clad into one. After ultrasonic testing, the composite rate of the entire weld is 100%. Sampling was carried out to test the bonding strength. The interface shear strength was ≥267Mpa, which was higher than the requirement of ≥196Mpa stipulated in the GB / T 8547-2006 "Titanium-Steel Composite Plate" standard. The interface was firmly bonded and a fully welded titanium-steel composite was obtained. ...

Embodiment 3

[0025] Two titanium-steel clad plates (the material combination is TA1 / 16MnR, the size is (8+60)×1400×2700mm) are welded together, and the weld length is 2700mm. The size of the arc-shaped titanium plate TA1 is 8×140×2800mm, the height of the support is 10mm, ammonium nitrate explosive is used, and it is directly placed on the upper surface of the arc-shaped titanium plate TA1, and the charge per unit area is 4.0g / cm 2 , use the No. 8 industrial electric detonator to detonate through the black wire explosive charge at the end, so that the titanium layer and the steel layer are clad into one. After ultrasonic testing, the composite rate of the entire weld is 100%. Sampling was carried out to test the bond strength. The interface shear strength was ≥292Mpa, which was higher than the requirement of ≥196Mpa stipulated in the GB / T 8547-2006 "Titanium-Steel Composite Plate" standard. The interface was firmly bonded and a fully welded titanium-steel composite was obtained. plate com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com