Argon arc welding automatic welding special machine

An automatic welding and argon arc welding technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems affecting human health, reduce labor costs, smooth the welding surface, and avoid injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

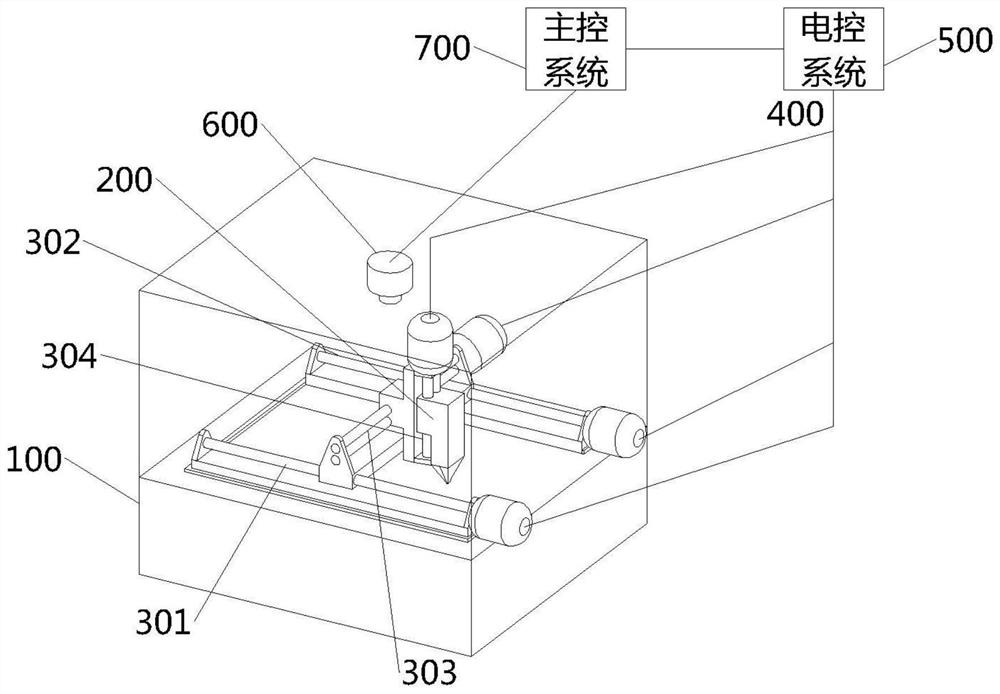

[0041] Such as figure 1 As shown, an automatic welding machine for argon arc welding includes a gantry welding frame 100, a welding torch 200, a screw drive system 300, a servo motor system 400, an electric control system 500, a vision system 600 and a main control system 700. The input end and the output end of the system 600 are respectively connected with the first output end and the first input end of the main control system 700, the input end of the electric control system 500 is connected with the second output end of the main control system 700, and the The output end of the electric control system 500 is connected to the input end of the servo motor system 400, the screw drive system 300 is driven by the servo motor system 400, and the screw drive system 300 is located in the On the gantry welding frame 100 , the welding torch 200 is arranged on the screw drive system 300 .

[0042] Such as figure 2 As shown, the workflow of the argon arc welding automatic welding m...

Embodiment 2

[0051] In this embodiment, on the basis of Embodiment 1, the vision system 600 uses an industrial camera.

Embodiment 3

[0053] In this embodiment, on the basis of Embodiment 1, the screw drive system 300 includes a first drive screw 301, a second drive screw 302, a third drive screw 303 and a fourth drive screw 304. The first driving screw 301 and the second driving screw 302 are arranged in parallel, the third driving screw 303 is perpendicular to the first driving screw 301, and the two of the third driving screw 303 The ends are movably connected to the screw mandrels of the first driving screw mandrel 301 and the second driving screw mandrel 302 respectively, and the described fourth driving screw mandrel 304 is vertically arranged on the described third driving screw mandrel 303, so The welding torch 200 is arranged on the fourth driving screw 304 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com