Optical identifying welding plate for printed circuit board and mfg. method

A printed circuit board, optical identification technology, applied in the direction of printed circuit components, electrical components to assemble printed circuits, etc., can solve the problems of poor identification point recognition effect, etc., to achieve the effect of high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

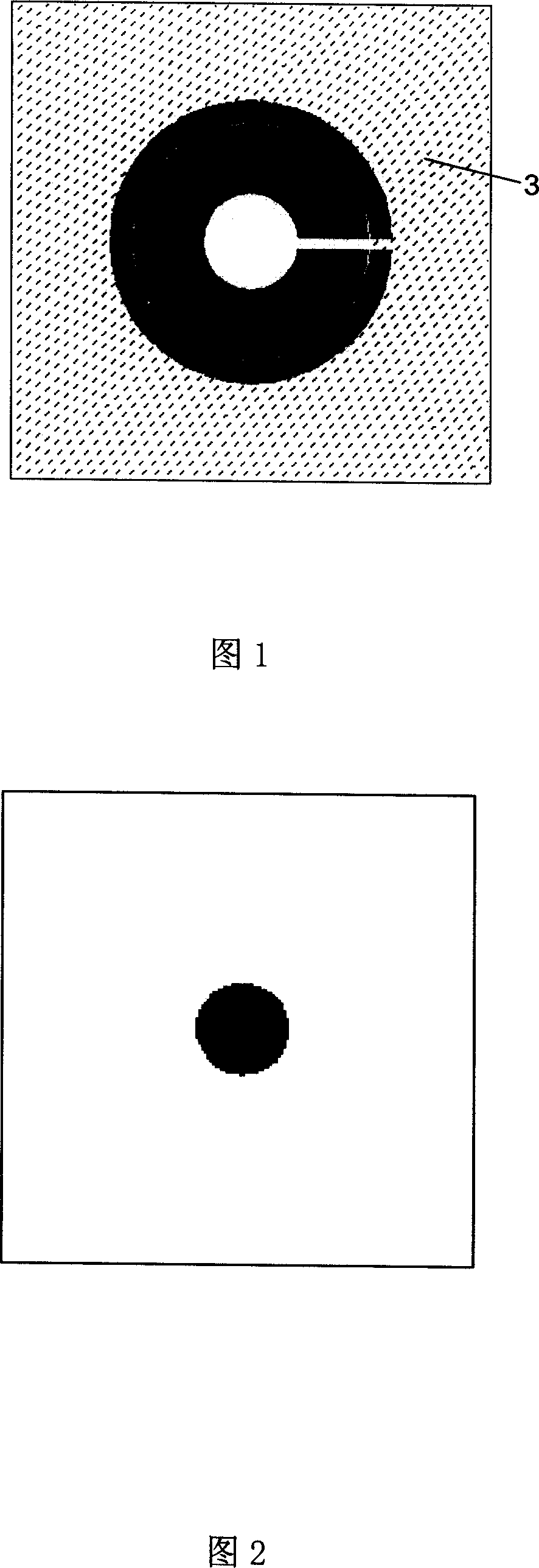

[0015] Embodiment 1: An optical identification pad of a printed circuit board, including a pad located on a printed circuit board, and an optical identification point on the pad, and the contrast between the optical identification point and the surrounding is different, so The above-mentioned optical recognition point is an etching point, and there is a solder resist area opening around the recognition point on the pad, and there is a plating layer in the solder resist opening area, and the plating layer can be a gold-plated layer. The etching point may be circular, the gold-plated layer is circular, and the welding pad is made of copper foil.

Embodiment 2

[0016] Embodiment 2: A method for manufacturing an optical identification point of a flexible printed circuit board, comprising the following steps: 1) removing a circular area on the copper foil to form an etching point, 2) performing solder resist on the pad, and the solder resist area An opening is formed around the identification point, and a plating layer is plated on the opening area of the solder resist around the identification point, and the plating layer is a gold-plated layer.

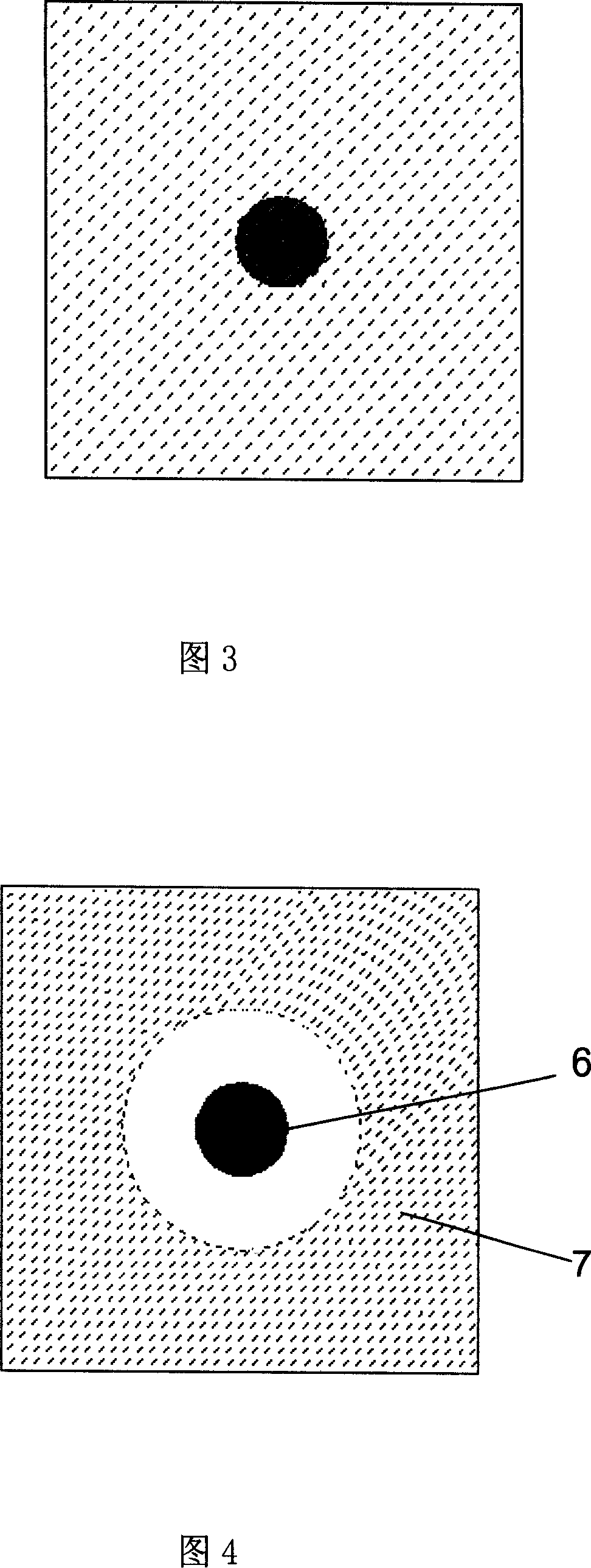

[0017] A double-sided flexible printed circuit board product needs to be equipped with various electronic components such as capacitors, resistors, connectors, and BGAs. As shown in Figure 2 and Figure 4, when making the circuit of the flexible printed circuit board, a circular mark (mark) point 6 is first etched on the copper foil. At this time, the mark (mark) point 6 is black, and then the copper foil is etched For solder masking of the foil, it is necessary to design a solder mask open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com