High alkalinity, low activity, superlow hydrogen sintering type solder

A low-activity, ultra-low hydrogen technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve the effect of improving low-temperature toughness, reducing diffusible hydrogen, and improving moisture absorption resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

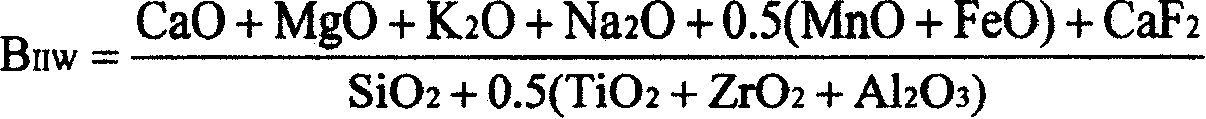

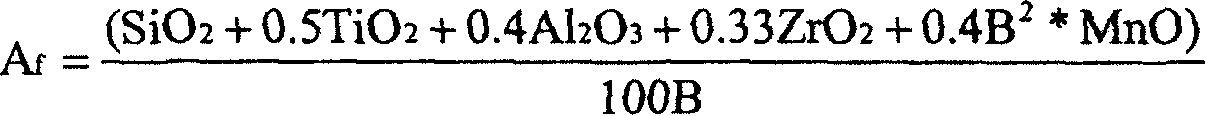

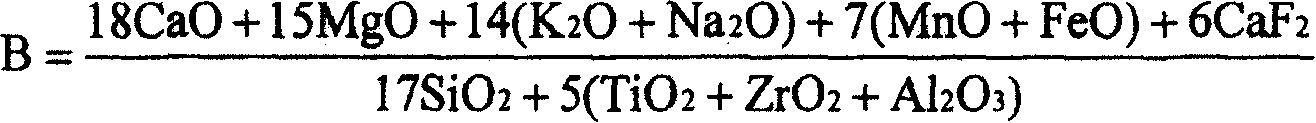

Method used

Image

Examples

Embodiment Construction

[0028] Propose embodiment of the present invention as follows:

[0029] The specific chemical composition of the embodiment is shown in Table 1, two kinds of 10NiCrMoTi welding wires and one kind of 05Ni3Mn2MoTi welding wires are used for welding. The steel plate welded by 10NiCrMoTi welding wire is 16mm thick 11MCrMoV steel plate, and the steel plate welded by 05Ni3Mn2MoTi welding wire is 24mm thick 10CrNi3MoV steel plate. The chemical composition of the two welding wires is shown in Table 2. The chemical composition and mechanical properties of the weld metal were measured after welding. Listed in Table 5.

[0030] The flux chemical composition (wt%) of the embodiment of table 1

[0031] category

MgO

CaF 2

al 2 o 3

SiO 2

CaCO 3

BaCO 3

Na 2 o

Li 2 CO 3

R E f

Example A

30

18

21

10

7

8

3

2

1

Example B

33

14

17

13

9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com