Brazing Processing Method of Inner Channel of Aluminum Parts

A processing method and internal channel technology, applied in the fields of metal processing and welding processing, can solve problems such as leakage, poor argon arc welding performance, and color difference in appearance, and achieve the effects of simple processing technology, low cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

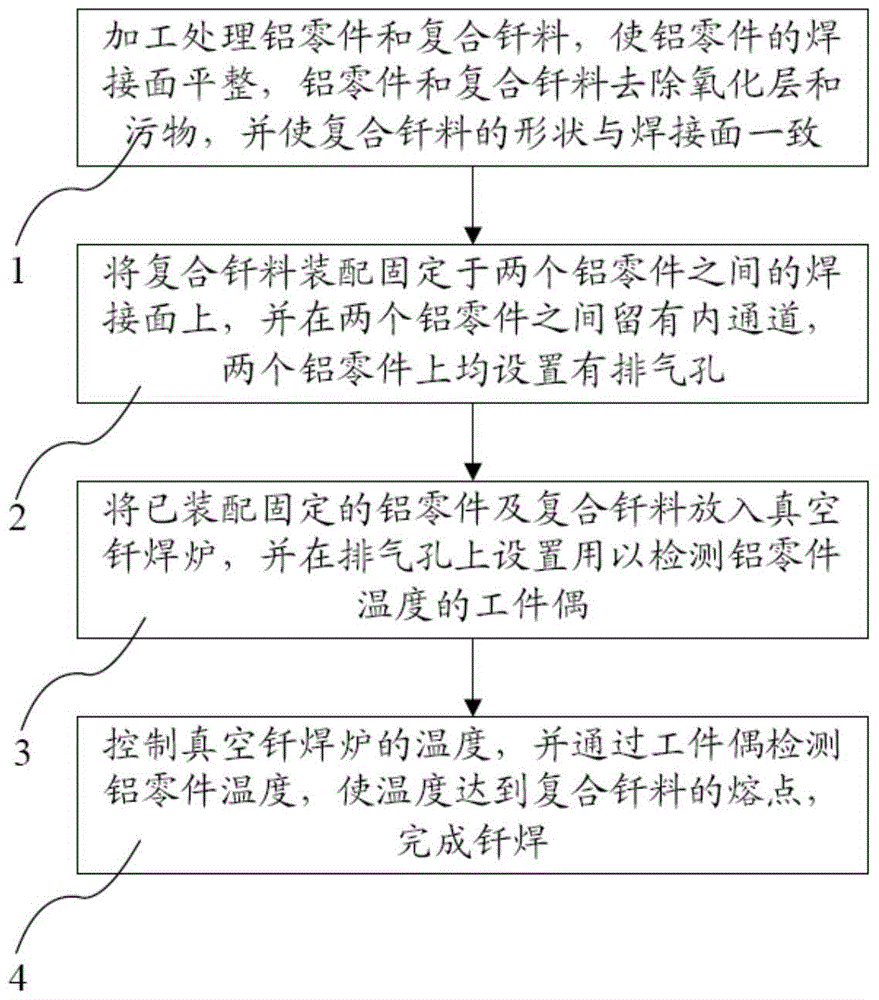

[0047] see figure 2 Shown is a flow chart of the steps of the aluminum part inner channel brazing processing method of the present invention.

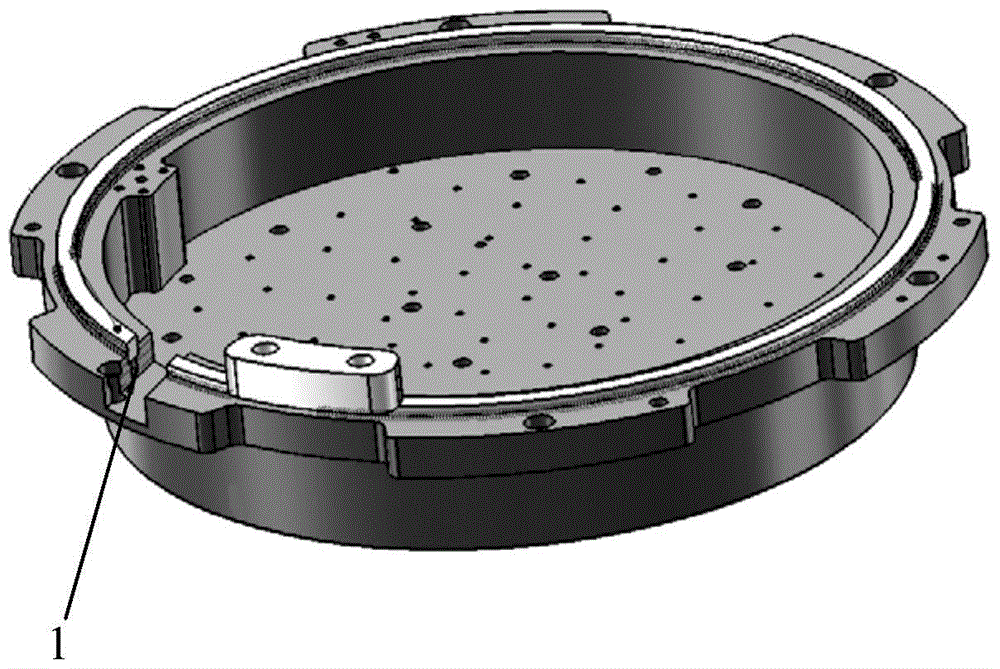

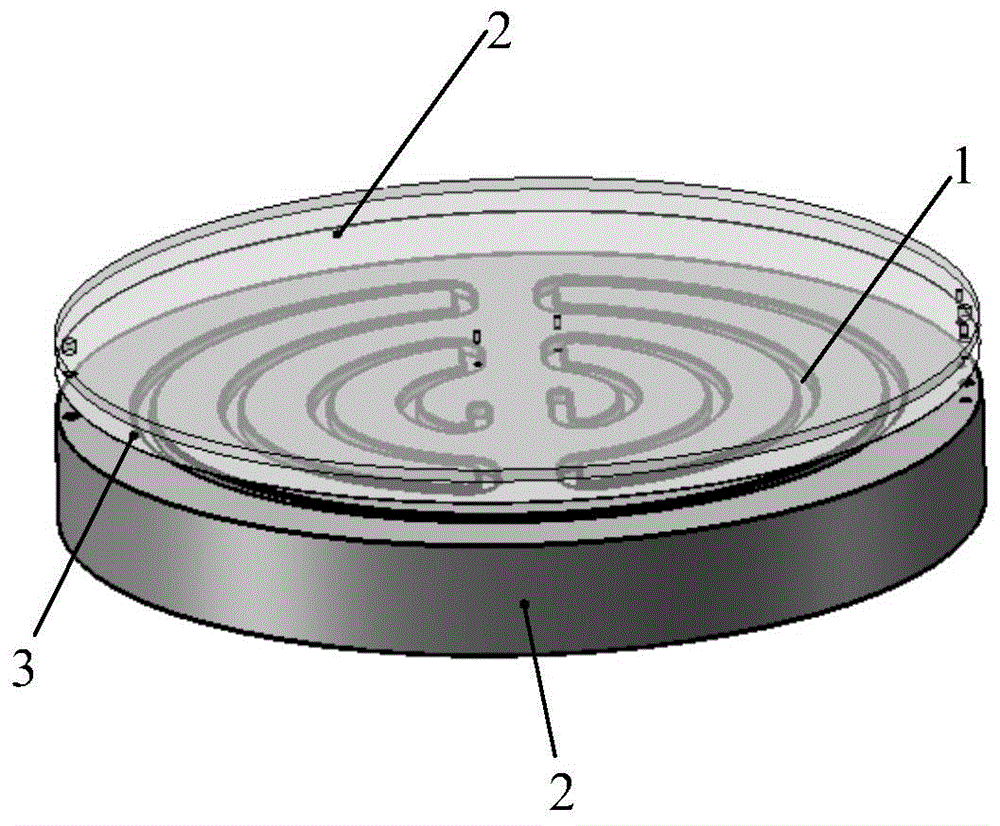

[0048] In one embodiment, as image 3 As shown, the inner channel 1 (water channel) is arranged on the welding surface between two aluminum parts 2, and the composite solder 3 is also arranged between the aluminum parts 2, and the brazing processing method of the inner channel of the aluminum part includes the following step:

[0049] (1) process the described aluminum part and composite brazing filler metal, make the welding surface of the described aluminum part smooth, aluminum parts and composite brazing filler metal remove oxide layer and dirt, and make the shape of composite brazing filler metal and described welding Consistent;

[0050] (2) Assembling and fixing the composite solder on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com