Multilayered steel armour

a technology of multi-layered steel and armour, applied in the direction of armour, protective equipment, armour plates, etc., can solve the problems of easy propagation of cracks, affecting the overall structural integrity of the armour, so as to enhance the overall structural integrity, eliminate deformation, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

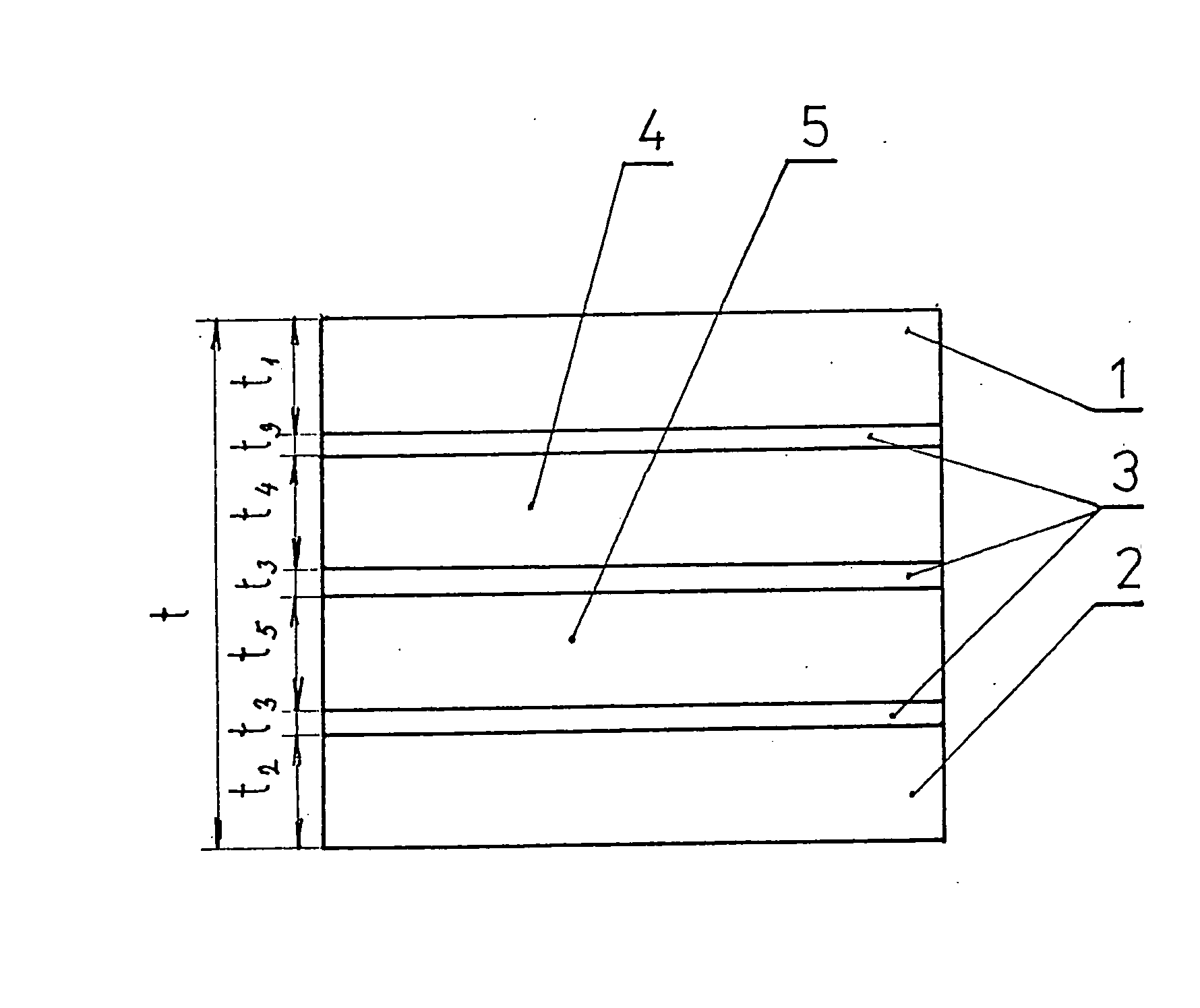

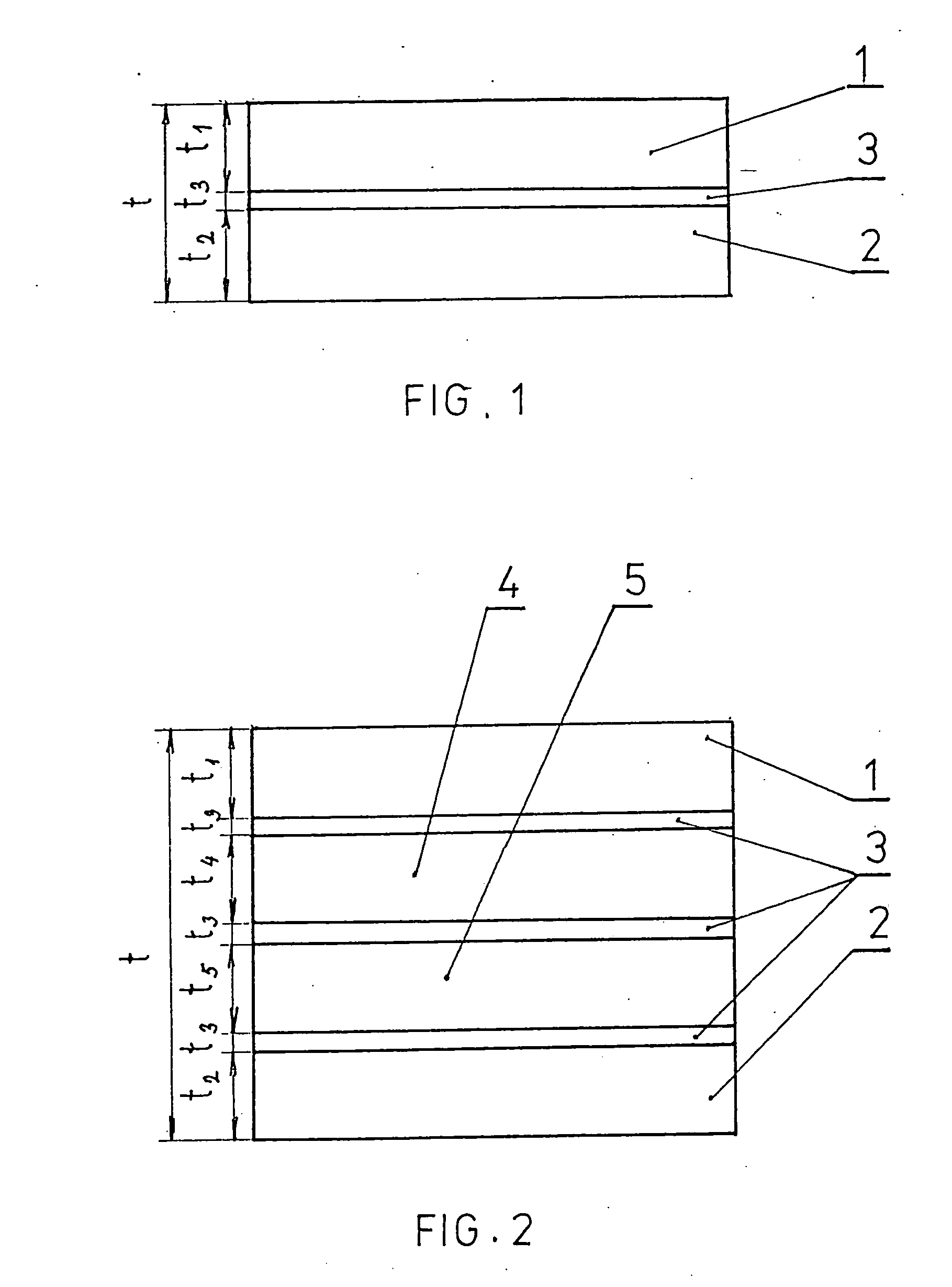

[0028] Multilayered steel armour according to this example, as in FIG. 1, comprises from the front-face ballistic-resistant layer 1 and from the backing armour layer 2.

[0029] The front-face ballistic-resistant armour layer 1 is made from steel alloy containing 0.66 wt % of carbon, 0.40 wt % of silicone, 0.40 wt % of manganese, no more than about 0.010 wt % of phosphorus, no more than about 0.010 wt % of sulfur, 1.20 wt % of chromium, 0.20 wt % of nickel, 0.20 wt % of vanadium, 1.90 wt % of tungsten, while the rest is iron and other accompanying elements and impurities.

[0030] The backing armour layer 2 is made from the steel alloy containing 0.30 wt % of carbon, 1.60 wt % of silicone, 1.40 wt % of manganese, no more than about 0.010 wt % of phosphorus, no more than about 0.008 wt % of sulfur, 0.40 wt % of chromium, 1.20 wt % of nickel, the rest is iron and other accompanying elements and impurities.

[0031] There is the joining metallic intermediate layer 3 located between the front...

example 2

[0034] Multilayered steel armour in this example represents the alternative implementation of the multilayered steel armour from the first example with the changed material of the inserted joining metallic intermediate layer 3. The material of this layer 3 was changed to the austenitic structure containing 10.6 wt % of nickel, 16.7 wt % of chromium, 2.2 wt % of molybdenum, 1.7 wt % of manganese, 0.5 wt % of silicone, 0.4 wt % of titanium, 0.03 wt % of carbon with the rest being iron and other usual admixtures and impurities.

[0035] This multilayered steel armour is prepared using the technology of multilayered casting, which is followed by the elevated temperature rolling process. The total thickness t of this multilayered steel armour is 7.5 millimeters, the thickness t1 of the front-face ballistic-resistance armour layer 1 is 3.5 millimeters, the thickness t2 of the backing armour layer 2 is 3.6 millimeters and the thickness t3 of the joining metallic intermediate layer 3 is 0.4 m...

example 3

[0036] The multilayered steel armour in this (third) example also represents the alternative implementation of the multilayered steel armour of the type introduced in the example 1. The difference is in a different composition of the joining metallic intermediate layer 3 joining the armour layer 1,2. The material of this layer 3 is the austenitic structure containing 12.5 wt % of manganese, 1.3 wt %. of carbon, 0.4 wt % of silicone while the rest is iron, other accompanying elements and usual impurities.

[0037] The total thickness t of this multilayered steel armour as well as the thickness t1 of the front-face ballistic-resistant armour layer 1 and the thickness t2 of the backing armour layer 2 and finally the thickness t3 of the joining metallic intermediate layer 3 are identical to thicknesses of the example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com