Explosive welding method for extra-thick plate

A technology of explosive welding and sheet metal, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as inability to complete high-quality products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be specifically described below.

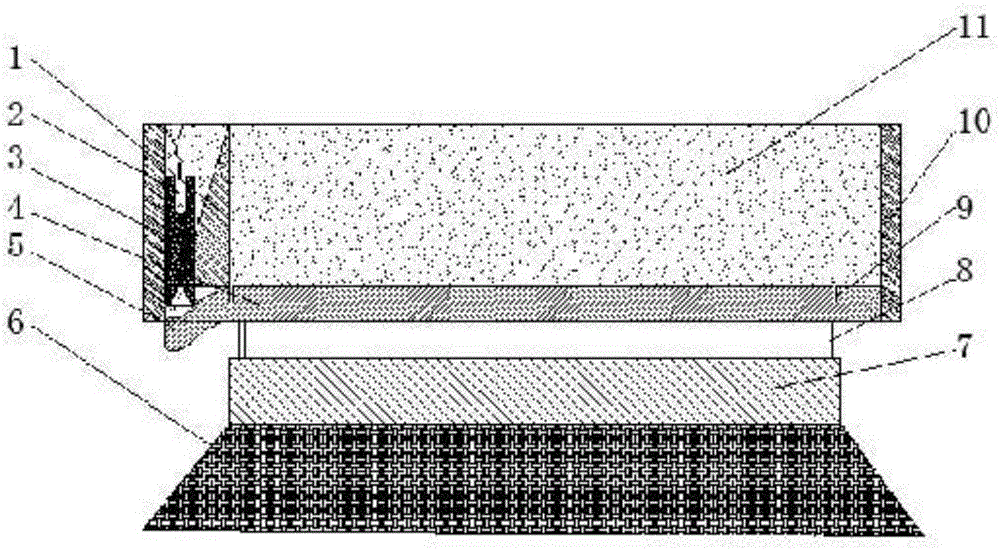

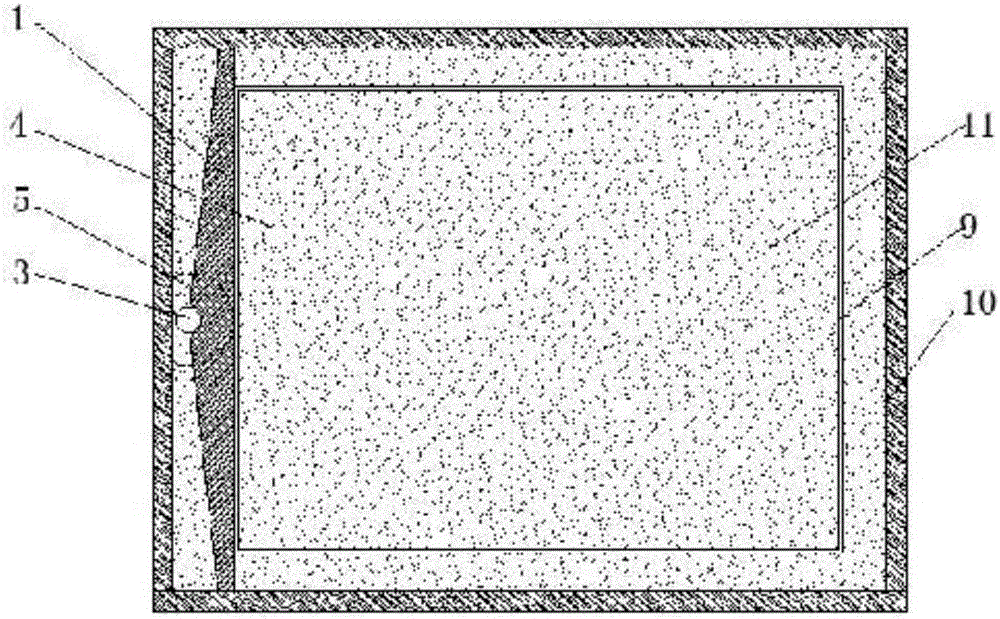

[0024] The ultra-thick cladding plate is pre-processed in the factory, and the cladding plate 4 is symmetrically drawn based on the size of the substrate, and the prefabricated crack 9 is opened to facilitate the unloading of detonation energy and prevent damage to the base plate; Use a hydraulic press to pre-press the detonation point 5 on the mold, and the pre-press depth is 2 / 3 of the support height, so as to facilitate the formation of oblique collisions.

[0025] For the explosive composite of ultra-thick cladding plates, the cladding plates are placed on the top during on-site installation, and the steel plate is used as the lower layer of substrate 7. First, the support gap between the two plates is increased, and the thickness of the cladding plate is 1.5 times. The support gap at the four corners of the edge, Placed in parallel, the prefabricated cracks in the cladding are aligned with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com