Explosive cladding method used for transition base plate of helicopter deck of drilling platform

A technology of helideck and drilling platform, which is applied in the field of explosive composite, can solve the problems of long delivery period, high price, unfavorable promotion and application of aluminum-titanium-steel composite plate equipment, etc., and achieve the effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

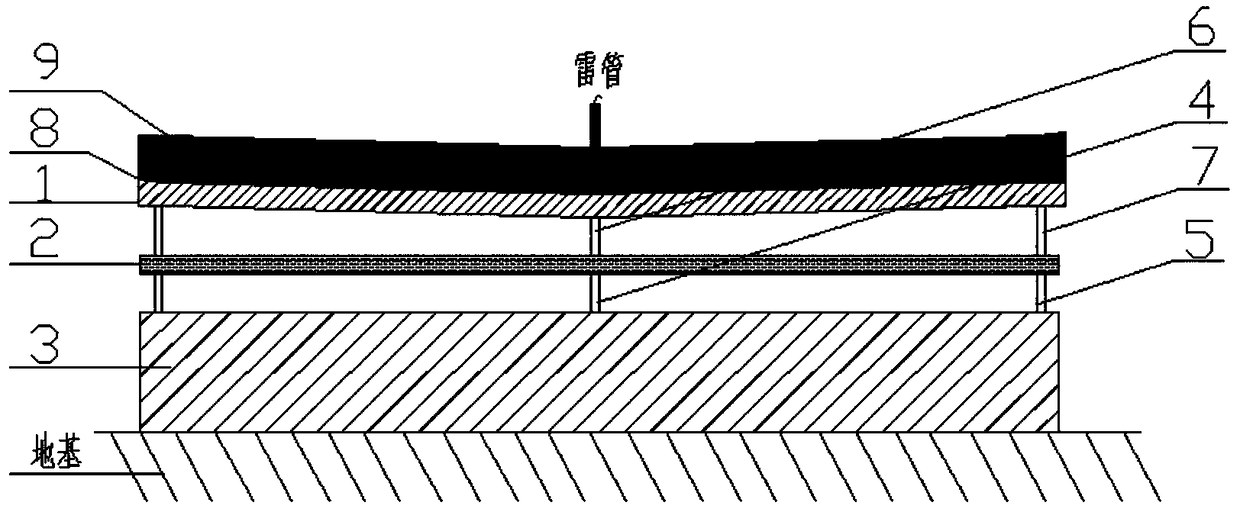

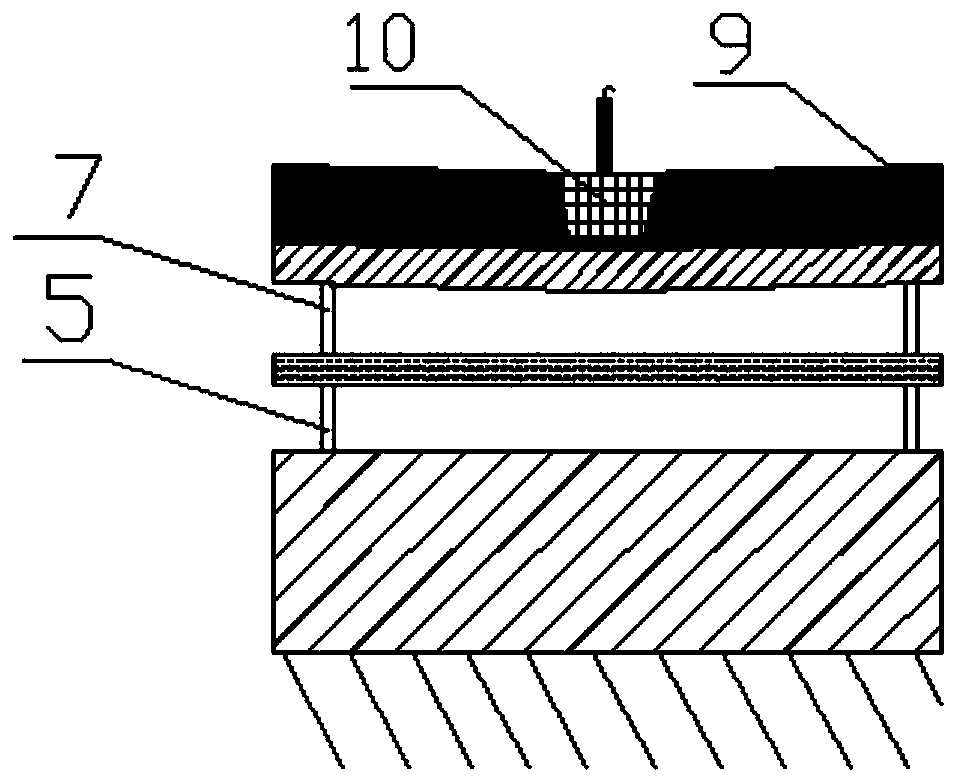

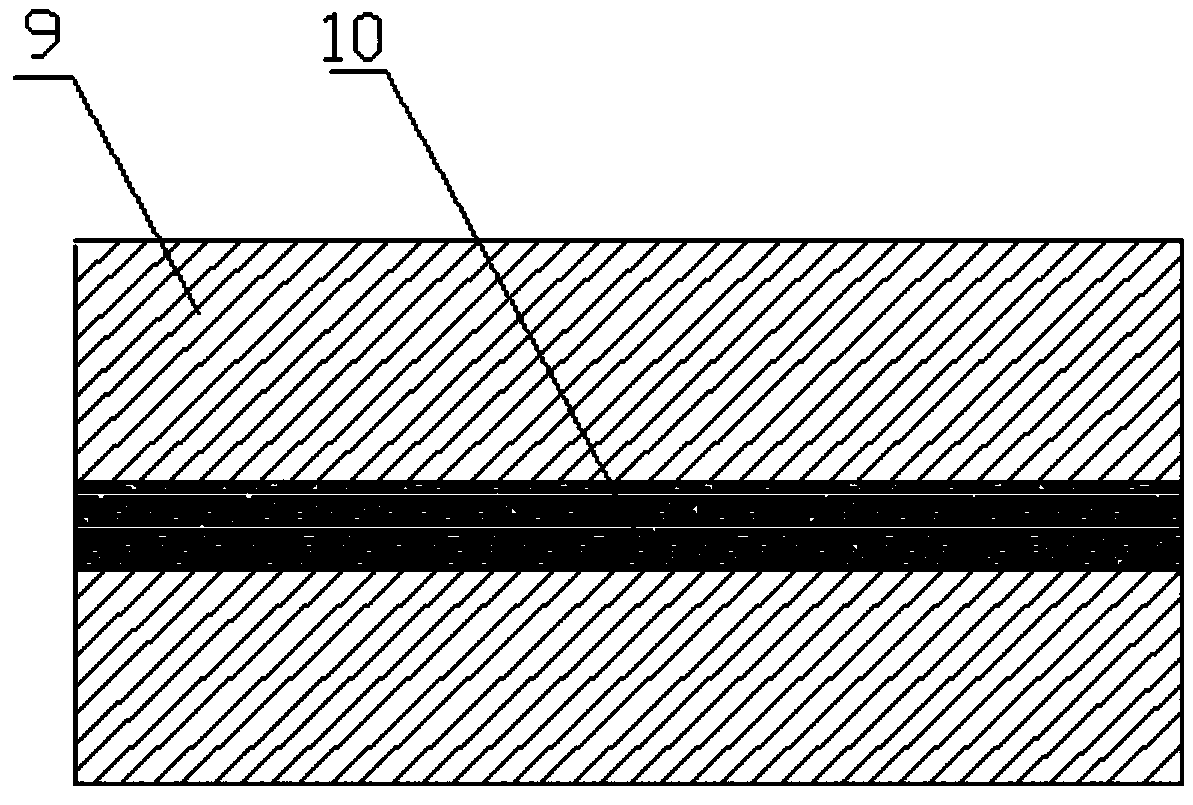

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims:

[0020] like Figure 1 ~ Figure 3 As shown, the present invention provides the explosive composite method for the transition backing plate of drilling platform helideck, comprising aluminum plate 1, titanium plate 2, steel plate 3, the method of the explosive welding forming of composite plate is as follows:

[0021] Step 1: The thickness of the selected aluminum plate 1 is 6mm, and the plate size is 4050mm×1650mm (L×W); the thickness of the titanium plate 2 is 3mm, and the plate size is 4050mm×1650mm (L×W); the steel plate adopts CCS B steel plate The steel plate 3 has a thickness of 50mm and a plate width of 4000mm×1600mm (L×W); clean the surfaces of the aluminum plate 1, titanium plate 2, and steel plate 3, so that the aluminum plate 1, tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com