Wood powder filled polypropylene and polyethylene composite material and preparation method for same

A technology of polypropylene and polyethylene, which is applied in the field of polymer materials, can solve the problems of inseparability, waste of polypropylene and polyethylene, insufficient raw materials of composite materials, etc., and achieve the effect of avoiding environmental pollution and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

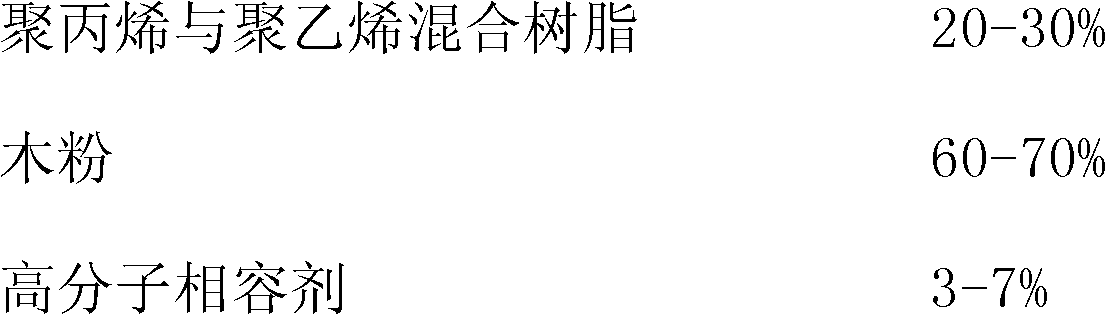

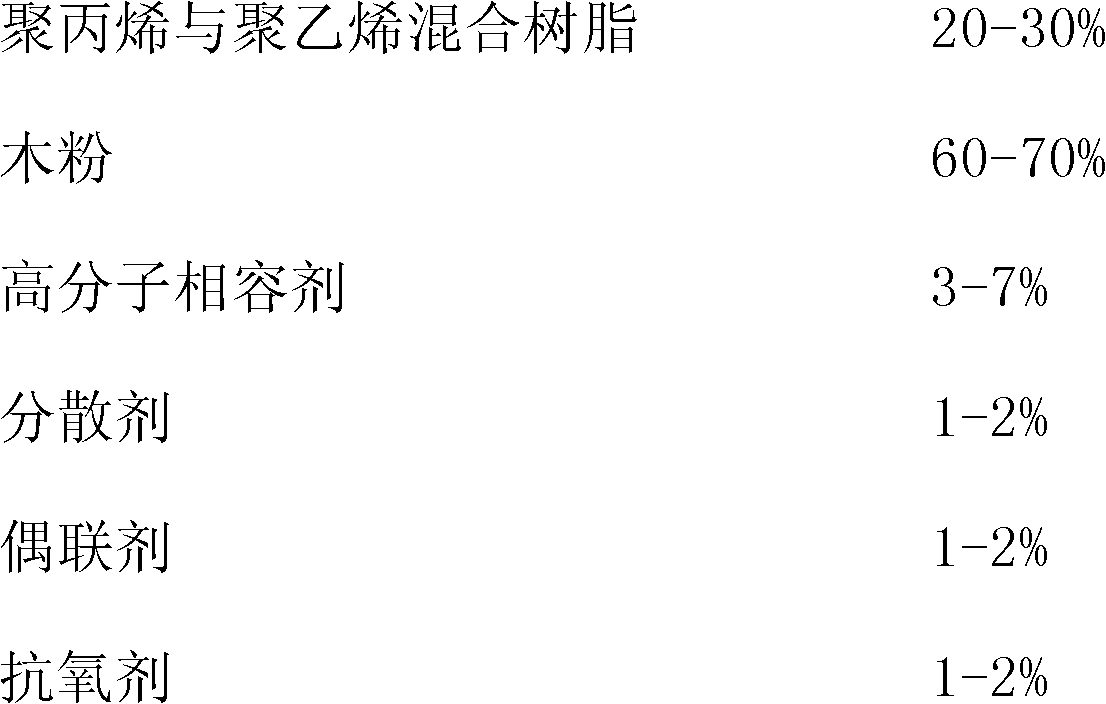

Method used

Image

Examples

Embodiment 1

[0025] According to the mass percentage content, 25% of PP and PE composite recycled materials (melt flow rate 18g / 10min), wood powder 65%, compatibilizer maleic anhydride grafted polyethylene 5%, dispersant (mass ratio MA4351: MA4352 =1:1) 2%, coupling agent 1.5%, antioxidant 1.5%.

[0026] Stir the wood flour and coupling agent on a high-speed mixer for 5-10 minutes, control the stirring temperature at 90-110°C, and complete the activation treatment on the surface of the wood flour;

[0027] Put the mixture of polypropylene and polyethylene and the polymer compatibilizer into the surface-activated wood powder, put the mixed material into medium-high speed and stir for 3-5 minutes, and control the stirring temperature at 70-80°C.

[0028] Put the dispersant and antioxidant into the above mixed material and stir at high speed for 3 to 5 minutes, and control the stirring temperature between 70-90°C;

[0029] Add the above mixed materials into the twin-screw extruder, and granu...

Embodiment 2

[0032] PP and PE composite regenerated material (melt flow rate 18g / 10min) 25%, wood flour 65%, compatibilizer maleic anhydride grafted ethylene-vinyl acetate copolymer 5%, dispersant (mass) Ratio MA4351:MA4352=1:1) 2%, coupling agent 1.5%, antioxidant 1.5% and mix uniformly in a high-speed mixer. The mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into alloy materials.

Embodiment 3

[0034] According to the mass percentage, PP and PE composite recycled materials (melt flow rate 18g / 10min) 25%, wood powder 65%, compatibilizer wood-plastic compatibilizer PF-6085%, dispersant (mass ratio MA4351:MA4352 =1:1) 2%, coupling agent 1.5%, and antioxidant 1.5% were mixed uniformly in a high-speed mixer. The mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into alloy materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com