Abrasion resistant extreme-pressure additive of borate and preparation method thereof

A technology of extreme pressure additives and borates, applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve the problems affecting the dropping point, consistency, mechanical stability, water resistance of lubricating grease, affecting the colloidal stability of products, and the inability of lubricating grease Application and other issues, to achieve outstanding anti-wear extreme pressure, long service life and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

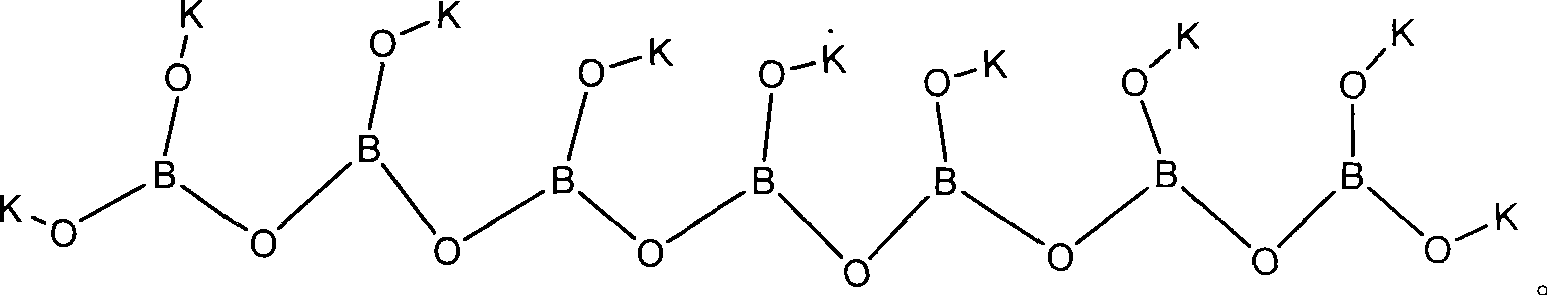

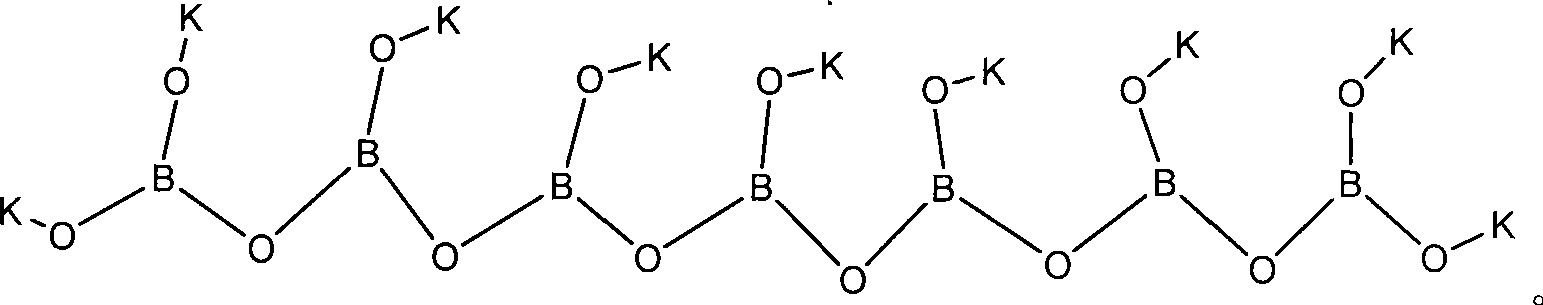

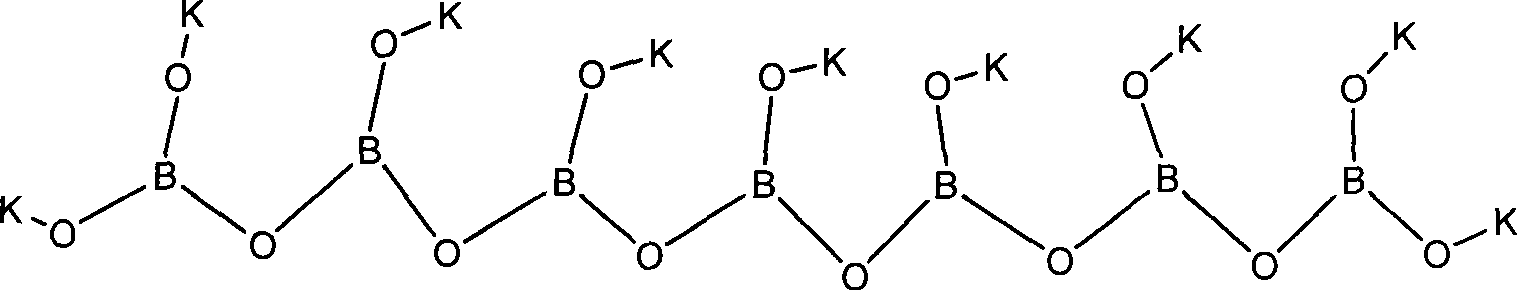

Image

Examples

Embodiment 1

[0036] Add 80Kg of water, 74.2Kg of boric acid and 33.6Kg of potassium hydroxide into the previously cleaned stainless steel reactor, stir, heat up to 75°C, and react for 40 minutes, add 90Kg of 600SN base oil, stir, and heat up to 110-120°C. Dehydrate for 50 minutes, heat up to 210°C, carry out high-temperature polymerization, 40 minutes, cool down to 180°C, add 6Kg lithium stearate and 2Kg 12-hydroxy calcium stearate, stir, 30 minutes, continue to cool down to 110°C, Take it out of the kettle, grind it on a three-roll mill, disperse homogeneously, and get the finished product.

Embodiment 2

[0038]Add 80Kg of water, 80.38Kg of boric acid and 36.47Kg of potassium hydroxide into the previously cleaned stainless steel reactor, stir, raise the temperature to 75, and react for 40 minutes, add 80Kg of 750SN base oil, stir, and raise the temperature to 110-120°C. Dehydrate for 58 minutes, heat up to 215°C, carry out high-temperature polymerization reaction, 45 minutes, cool down to 180°C, add 5Kg sodium stearate and 3Kg 12 hydroxylithium stearate, stir for 25 minutes, continue to cool down to 110°C, Take it out of the kettle, grind it on a three-roll mill, disperse homogeneously, and get the finished product.

[0039] Table The detection data of borate anti-wear extreme pressure additives and their influence on the water resistance of urea-based grease

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com