Carbon steel and austenitic stainless steel combined steel plate and production method thereof

A technology of austenitic stainless steel and composite steel plate, which is applied in natural gas steel pipe, carbon steel and austenitic stainless steel composite steel plate and its production, manufacturing and transportation of corrosive petroleum fields, and can solve the problem that carbon steel cannot meet the corrosion resistance requirements, etc. problem, to achieve good resistance to hydrogen-induced cracking, good resistance to intergranular corrosion, and good composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

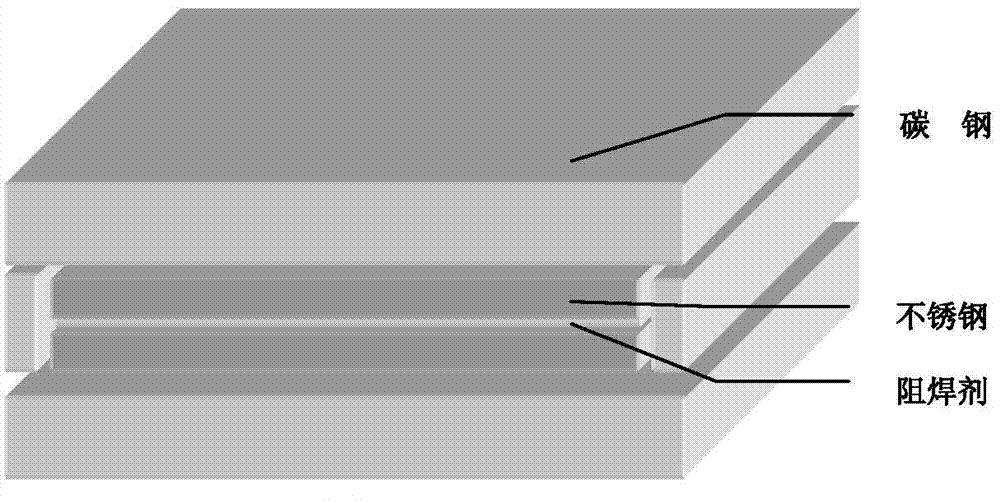

[0021] The chemical composition of steel base material X70 in this experiment is C: 0.06%, Si: 0.02%, Mn: 1.55%, P: 0.005%, S: 0.002%, Alt: 0.03%, N: 0.005%, H: 0.0001%, in addition Ni: 0.10%, Cr: 0.15%, Nb: 0.02%, Ti: 0.015%. The composition of the clad layer 316L meets the requirements of the ASTM A240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C: 0.02%, Mn: 1.0% , Si: 0.4%, P: 0.03%, S: 0.01%, Cr: 16.5%, Ni: 10%, Mo: 2%. The steel plate specification is: (20+3)×2040×12000mm (thickness×width×length), of which the thickness of X70 is 20mm, and the thickness of stainless steel is 3mm.

[0022] The production process includes billet formation, heating, direct rolling, and warm water cooling, specifically:

[0023] (1) The steel billet smelted according to the chemical composition is designed and smelted for billet rolling; the carbon st...

Embodiment 2

[0030] The chemical composition of steel base material X70 in this experiment is C: 0.06%, Si: 0.02%, Mn: 1.55%, P: 0.005%, S: 0.002%, Alt: 0.03%, N: 0.005%, H: 0.0001%, in addition Ni: 0.10%, Cr: 0.15%, Nb: 0.02%, Ti: 0.015%. The composition of the clad layer 316L meets the requirements of the ASTM A240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C: 0.02%, Mn: 1.0% , Si: 0.4%, P: 0.03%, S: 0.01%, Cr: 16.5%, Ni: 10%, Mo: 2%. The specifications of the steel plate are: (16+3)×2060×12000mm (thickness×width×length), of which the thickness of X70 is 16mm, and the thickness of stainless steel is 3mm.

[0031] The production process includes billet formation, heating, direct rolling, and warm water cooling, specifically:

[0032] (1) The steel billet smelted according to the chemical composition is designed and smelted for billet rolling; the ...

Embodiment 3

[0039] The chemical composition of steel base material X70 in this experiment is C: 0.06%, Si: 0.02%, Mn: 1.55%, P: 0.005%, S: 0.002%, Alt: 0.03%, N: 0.005%, H: 0.0001%, in addition Ni: 0.10%, Cr: 0.15%, Nb: 0.02%, Ti: 0.015%. The composition of the clad 316L meets the requirements of the ASTM A240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C: 0.02%, Mn: 1.0% , Si: 0.4%, P: 0.03%, S: 0.01%, Cr: 16.5%, Ni: 10%, Mo: 2%. The steel plate specification is: (14+3)×1860×12000mm (thickness×width×length), of which the thickness of X70 is 14mm, and the thickness of stainless steel is 3mm.

[0040] The production process includes billet formation, heating, direct rolling, and warm water cooling, specifically:

[0041] (1) The steel billets smelted according to the chemical composition are designed and smelted for billet rolling; the carbon steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com