Carbon steel and duplex stainless steel composite steel plate and production method thereof

A technology of duplex stainless steel and clad steel plate, used in temperature control, metal rolling, etc., to achieve the effect of good composite effect, good resistance to intergranular corrosion, and excellent strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

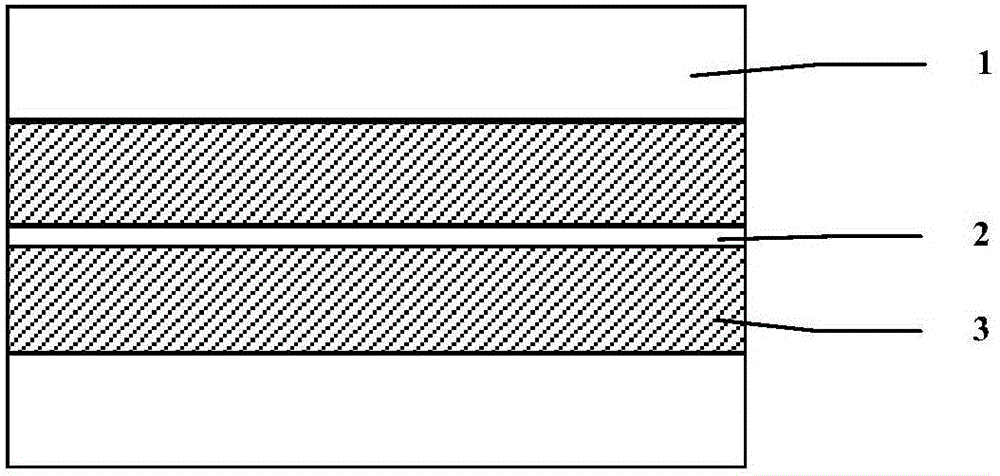

[0018] The chemical composition of steel base Q245R carbon steel 1 in this experiment is C: 0.17%, Si: 0.25%, Mn: 0.9%, P: 0.01%, S: 0.00%, Alt: 0.04%, and the balance is Fe and unavoidable impurities element. The three components of the clad S32205 duplex stainless steel meet the requirements of the ASTMA240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C: 0.03%, Mn: 1.2%, Si: 0.5%, and also contains Cr: 22.5%, Ni: 5%, Mo: 3% and other alloying elements to increase corrosion resistance. The steel plate specifications are: (10+3) mm thick × 2040 mm wide × 12000 mm long, of which Q245R carbon steel 1 has a thickness of 10 mm, and S32205 duplex stainless steel 3 has a thickness of 3 mm.

[0019] The production process includes billet assembly, heating, direct rolling, and air cooling, specifically:

[0020] (1) The steel billet designed and...

Embodiment 2

[0026] The chemical composition of steel base Q245R carbon steel 1 in this experiment is C: 0.17%, Si: 0.25%, Mn: 0.9%, P: 0.01%, S: 0.00%, Alt: 0.04%, and the balance is Fe and unavoidable impurities element. The three components of the clad S32205 duplex stainless steel meet the requirements of the ASTMA240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C: 0.03%, Mn: 1.2%, Si: 0.5%, and also contains Cr: 22.5%, Ni: 5%, Mo: 3% and other alloying elements to increase corrosion resistance. The steel plate specifications are: (16+3) mm thick × 2060 mm wide × 12000 mm long, of which Q245R carbon steel 1 has a thickness of 16 mm, and S32205 duplex stainless steel 3 has a thickness of 3 mm.

[0027] The production process includes billet assembly, heating, direct rolling, water cooling, and tempering treatment, specifically:

[0028] (1) The st...

Embodiment 3

[0036] The chemical composition of steel base Q245R carbon steel 1 in this experiment is C: 0.17%, Si: 0.25%, Mn: 0.9%, P: 0.01%, S: 0.00%, Alt: 0.04%, and the balance is Fe and unavoidable impurities element. The three components of the clad S32205 duplex stainless steel meet the requirements of the ASTMA240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C: 0.03%, Mn: 1.2%, Si: 0.5%, and also contains Cr: 22.5%, Ni: 5%, Mo: 3%, etc. to increase corrosion resistance alloying elements. The steel plate specifications are: (26+4) mm thick × 1860 mm wide × 12000 mm long, of which Q245R carbon steel 1 has a thickness of 26 mm, and S32205 duplex stainless steel 3 has a thickness of 4 mm.

[0037] The production process includes billet assembly, heating, direct rolling, and water cooling, specifically:

[0038] (1) The steel billet designed and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com