Insulation coating composition for electrical steel

A composite, electrical steel sheet technology, applied in inorganic insulators, organic insulators, nanotechnology for materials and surface science, etc., to achieve the effects of low stack shrinkage, good pressure resistance, and excellent corner coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6

[0063] Preparation of the coating of the present invention based on C5 electrical insulating varnish

[0064] A dispersion of aliphatic polyurethane (a water-based system with a solids content of 34 to 40% by weight) was mixed with a dispersion of nanoscale silica (a basic water-based system with a solids content of 35 to 40% by weight). A crosslinking agent (solids content 35 to 100% by weight), pigments, fillers and additives are added to the mixture, wherein 0.5 to 1.5 parts by weight of coated silica gel is used as welding additive, 0 to 3 parts by weight Aminocarboxyl compounds are used as corrosion inhibitor additives and 0 to 2 parts by weight of defoamer additives. The mixture was stirred well to provide six different coating compositions of the present invention as C5 paints with different crosslinkers.

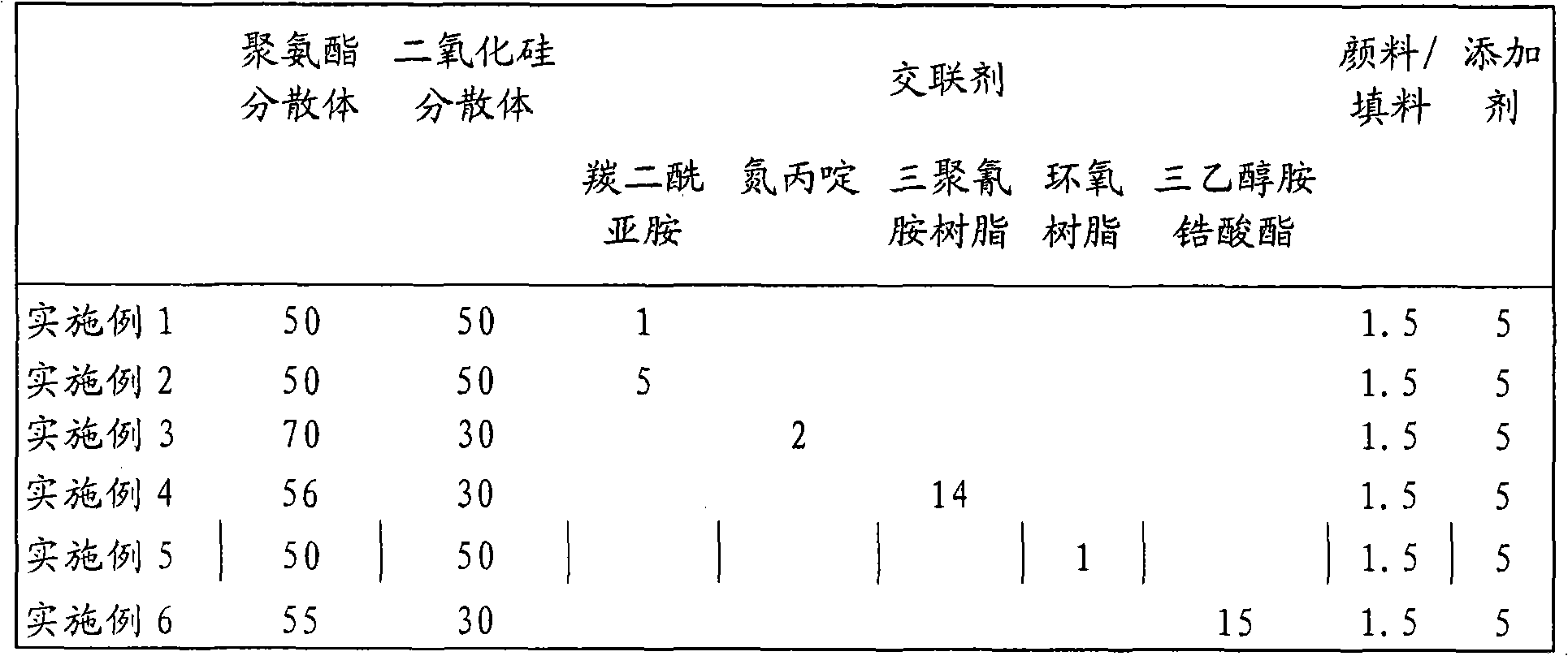

[0065] The paint composition is shown in Table 1. The dosage is in parts by weight.

[0066] Table 1 :

[0067]

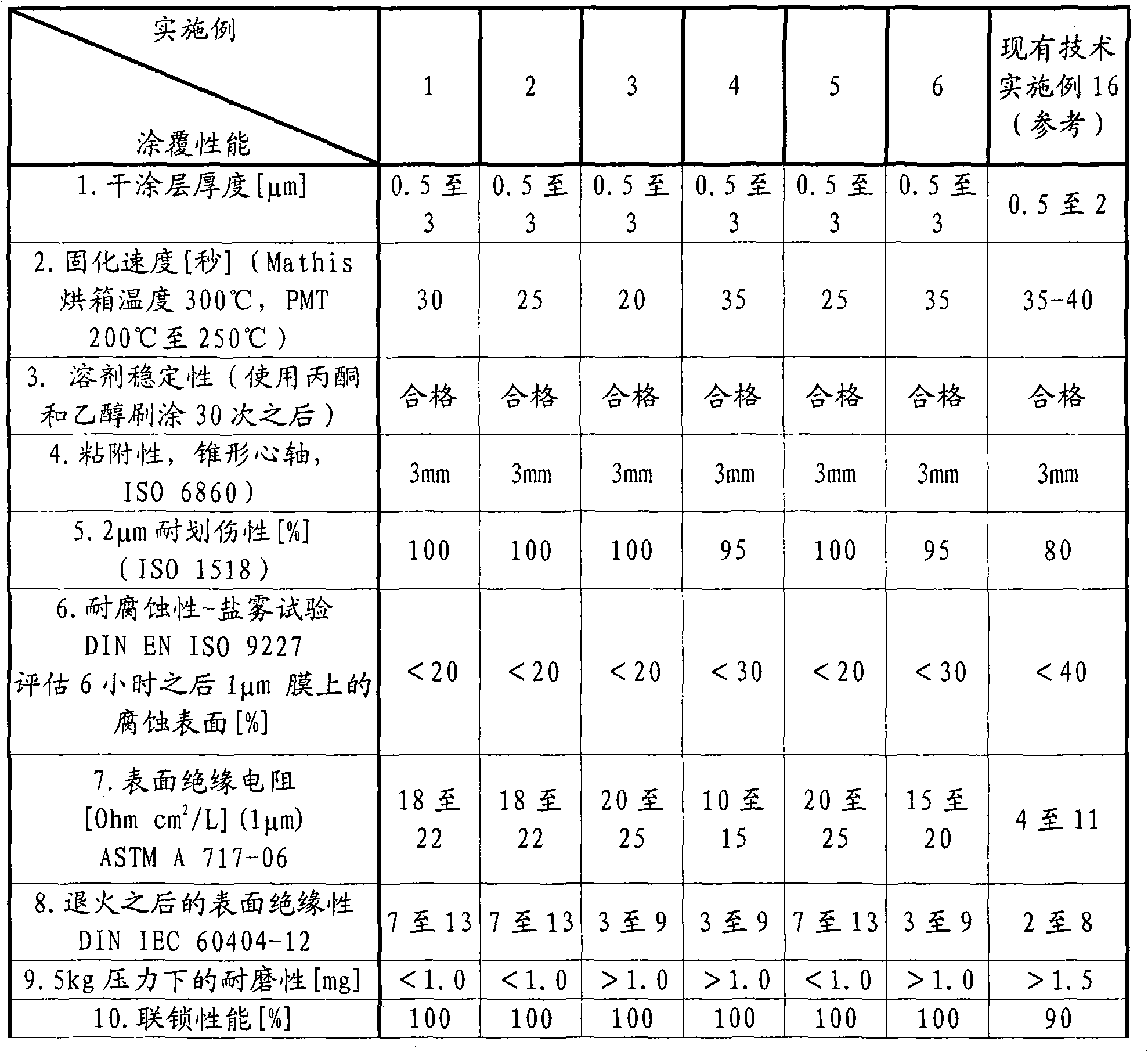

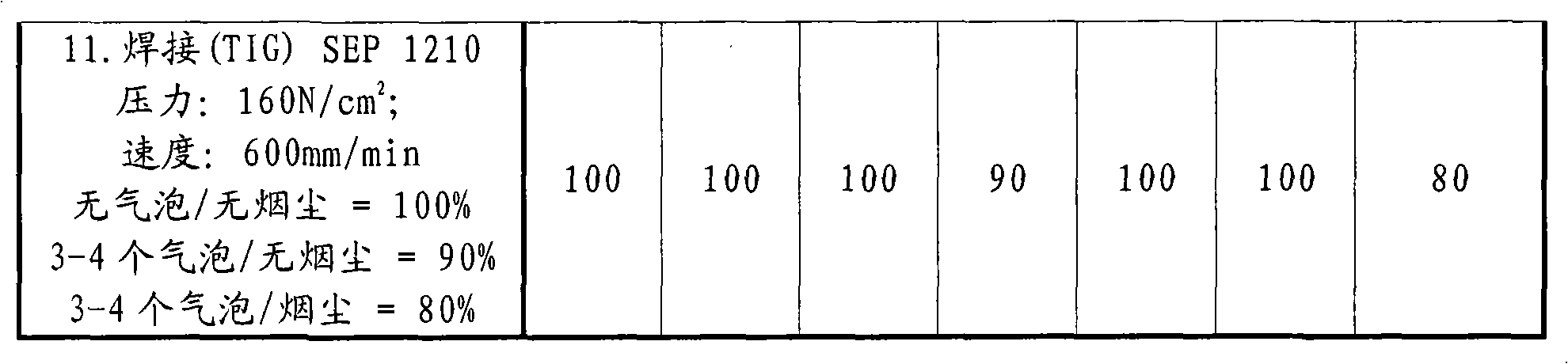

[0068] Each coating composition listed i...

Embodiment 7 to 10

[0076] Preparation of the coating of the present invention based on C6 electrical insulating varnish

[0077] The preparation method is the same as described in Examples 1 to 6. Stir the mixture and grind until smooth.

[0078] The composition of the C6 paint with different crosslinkers is shown in Table 3. The dosage is in parts by weight.

[0079] table 3 :

[0080]

[0081] Using the same methods and conditions as described in Examples 1 to 6, the coating compositions shown in Table 3 were applied to electrical steel panels and cured thereon to form coatings having a dry film thickness of 6 μm (+ / -0.7). insulation layer. After curing, the coated steel plates are stacked and assembled by welding to form the core.

[0082] The technical performance compared with the prior art is described in Table 4.

[0083] Table 4 :

[0084]

Embodiment 11 to 14

[0086] Preparation of the coating of the present invention based on C3 electrical insulating varnish

[0087] The preparation method is the same as described in Examples 1 to 6.

[0088] The composition of C3 paints with different crosslinkers is described in Table 5. The dosage is in parts by weight.

[0089] table 5 :

[0090]

[0091] Using the same method and conditions as described in Examples 1 to 6, the coating composition shown in Table 5 was applied to electrical steel panels and cured thereon to form a coating having a dry film thickness of 4 μm (+ / -0.4). Insulation. After curing, the coated steel plates are stacked and assembled by welding to form the core.

[0092] The technical performance compared to the prior art is described in Table 6.

[0093] Table 6 :

[0094]

[0095]

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com