Electric insulation material, an electric device and a method for producing an electric insulation material

A technology of electrical insulating materials and filler particles, which is applied in the direction of organic insulators, inorganic insulators, plastic/resin/wax insulators, etc., and can solve the problems of peeling and destructive electrical insulating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

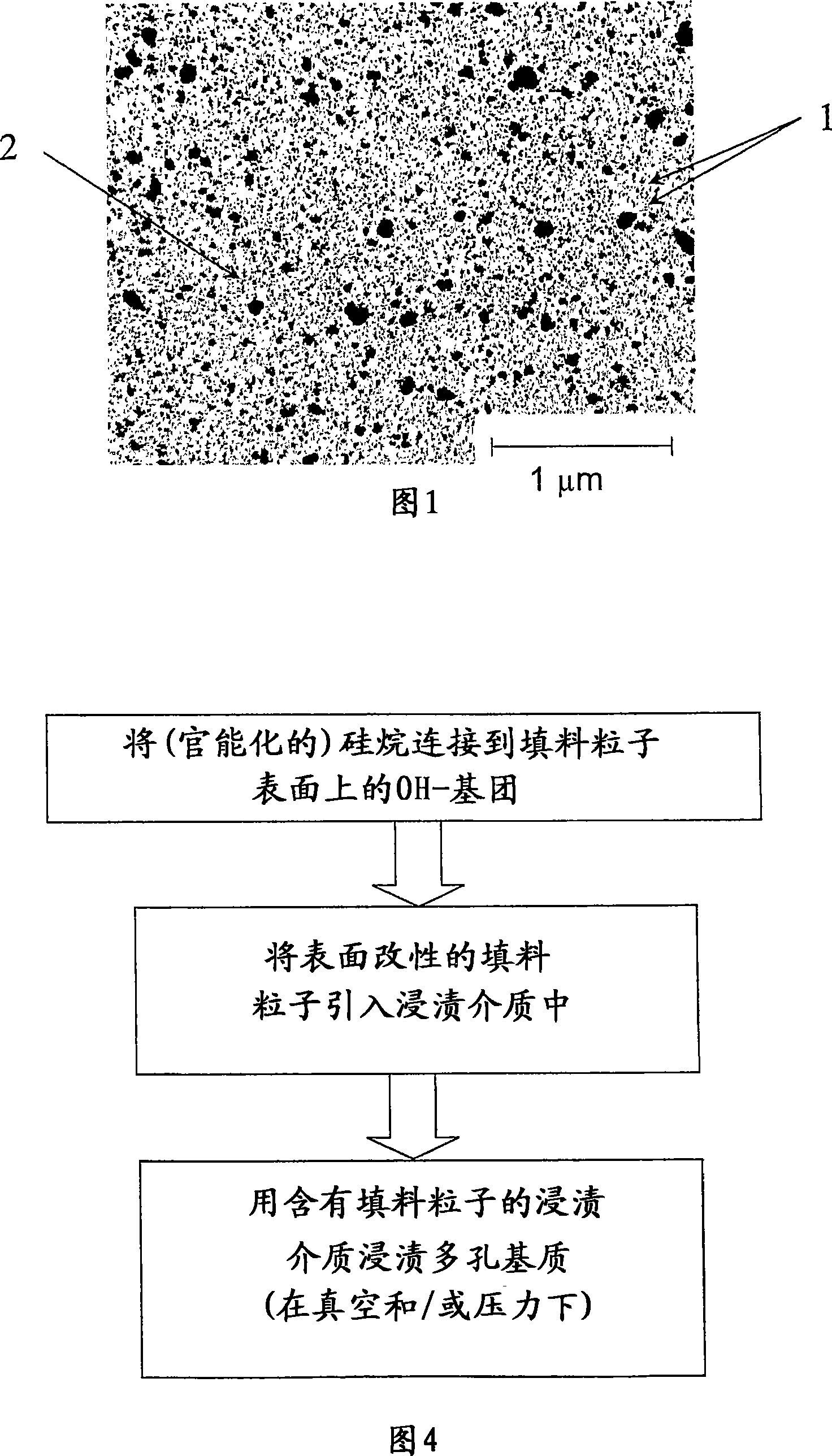

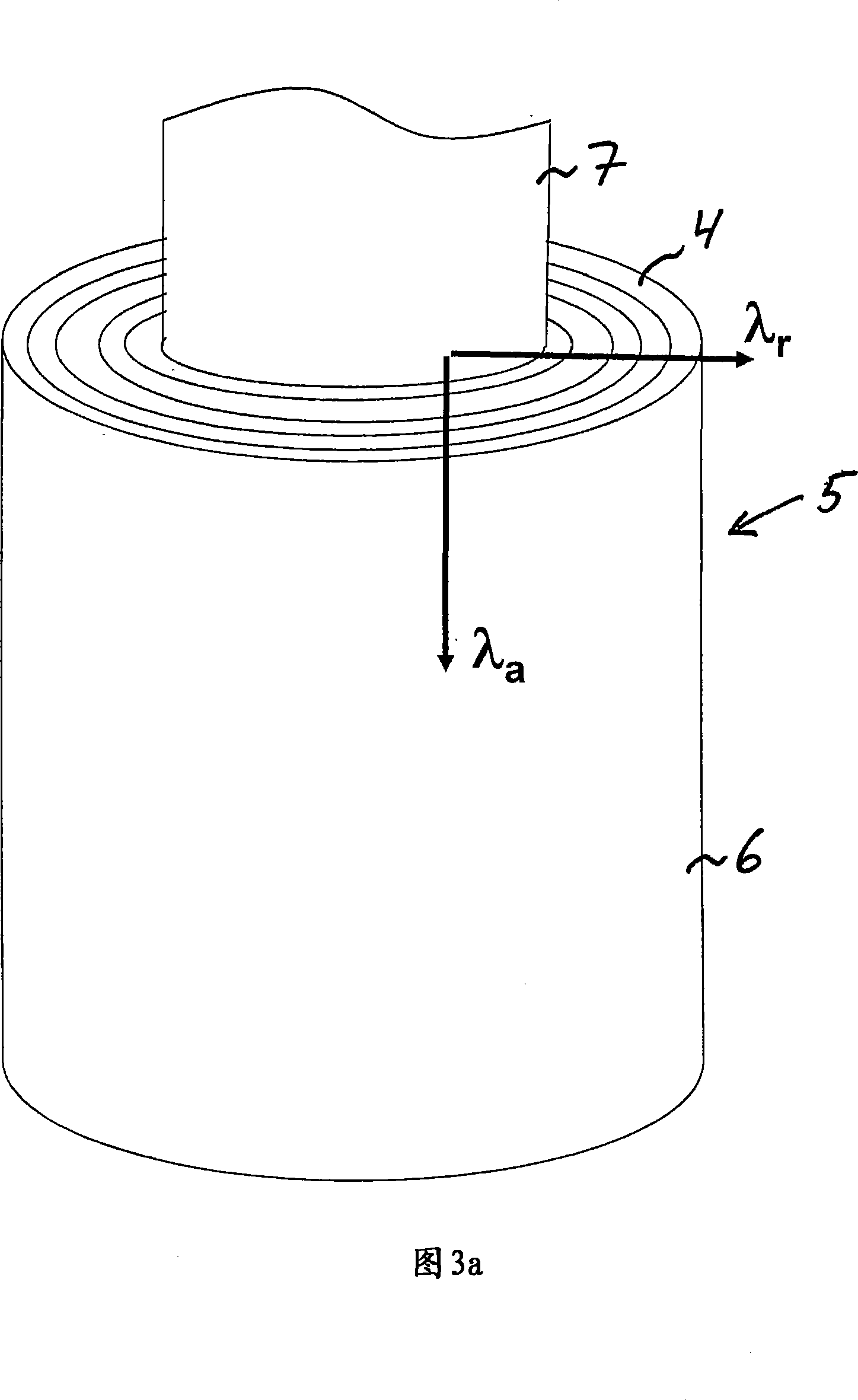

[0031] Figure 1 is a graph showing 50nm Al dispersed in an impregnation medium in the form of epoxy resin 2 2 o 3 TEM micrograph of Nanoparticle 1. Such an impregnation medium 2 comprising filler particles 1 can be produced simply by combining and mixing the particles 1 and the impregnation medium 2, preferably at room temperature or by conventional melt mixing. Surface modification of the Al with (3-glyceroxypropyl)trimethoxysilane 2 o 3 nanoparticles 1, and deagglomerated before introducing them into the epoxy resin 2. It has been found that with the present invention having 25 volume % 300nmAl 2 o 3 The insulation material of the impregnation medium with filler content replaces its conventional electrical insulation material, which can increase the radial thermal conductivity of the RIP sleeve by 150%.

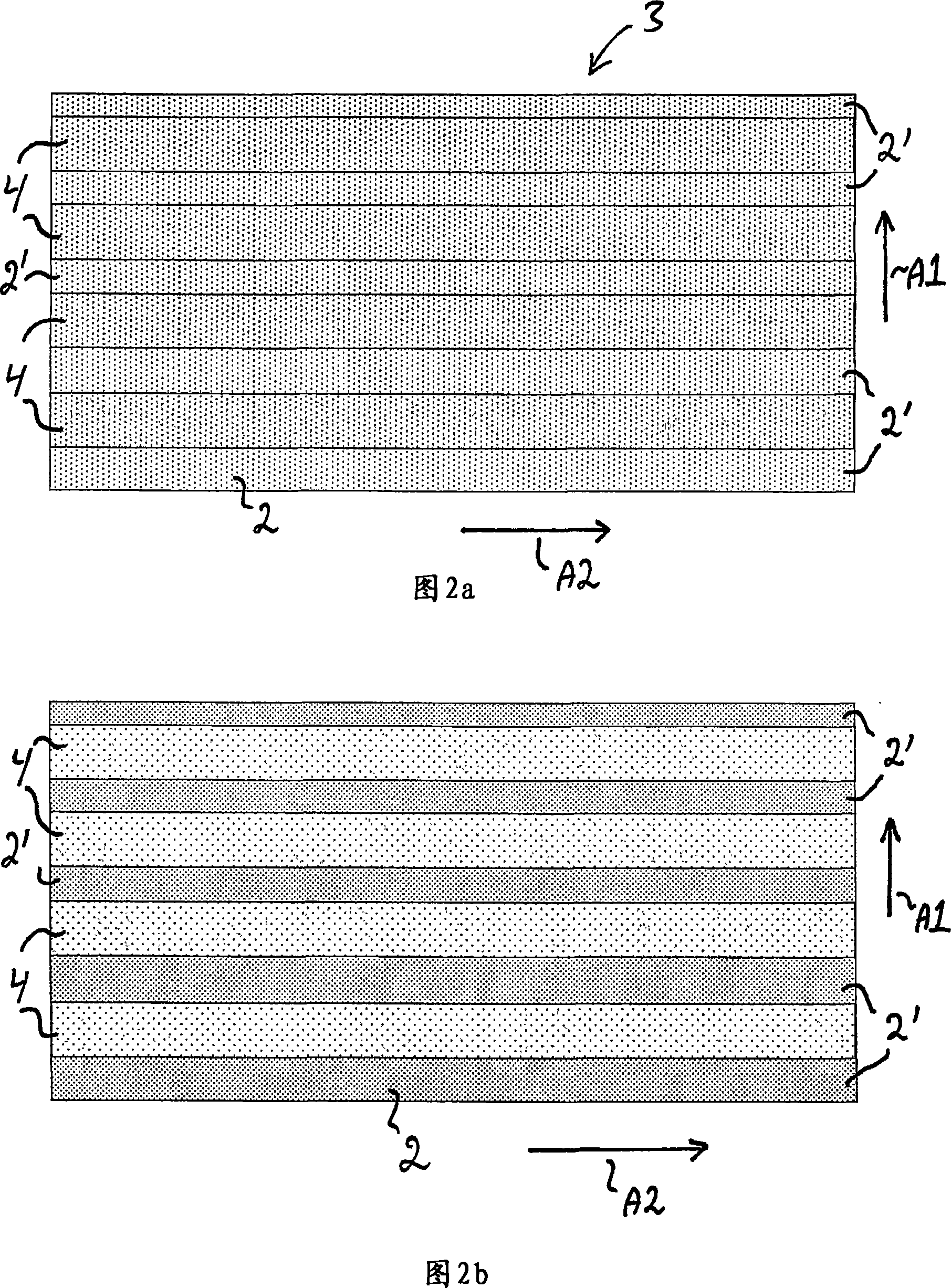

[0032]Figure 2a shows an electrical insulation material 3 formed by several layers of a porous cellulose matrix 4 impregnated with an impregnation medium 2 comprising...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com