Electric machine stator component and electric machine

A motor stator and stator winding technology, applied in the direction of electric components, electrical components, organic insulators, etc., can solve problems such as difficult operation, low production efficiency, and difficult quality control, and achieve the effect of improving insulation performance and increasing creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

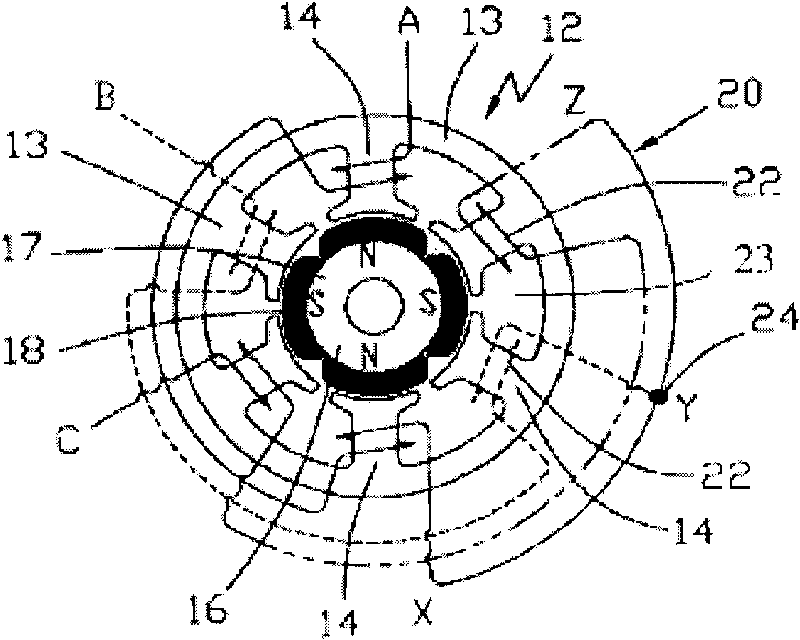

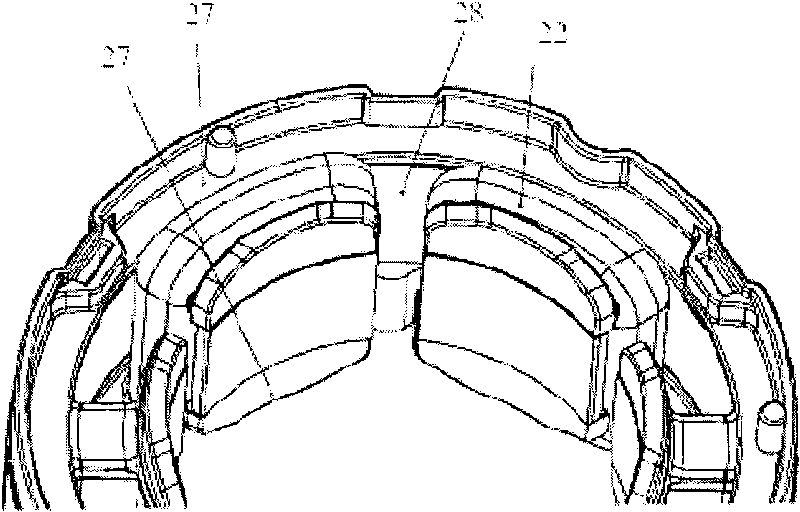

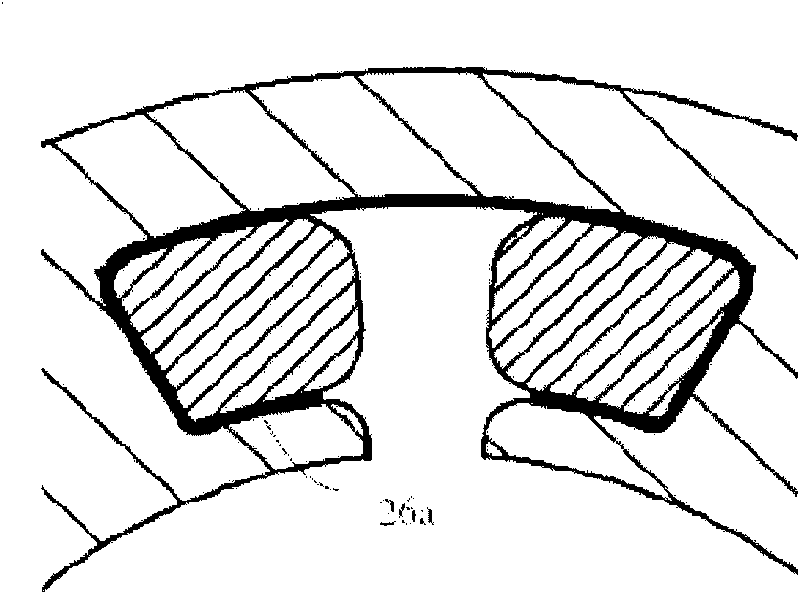

[0017] see Figure 4 to Figure 6 , the motor stator assembly 100 according to an embodiment of the present invention includes a stator core and a stator winding. The stator core is substantially cylindrical, and has six stator poles extending radially inward along the stator core, preferably, each stator pole is evenly spaced along the circumferential direction; the stator pole has a radially extending neck 112 and the pole piece 113 extending circumferentially at the end of the neck, the stator poles are connected by a yoke 114, two adjacent stator poles and the yoke connecting the two stator poles form a core groove 115. The core slot 115 has notches 116 formed by the pole shoes of the two stator poles. The stator windings form a coil 121 on each stator pole with slot insulation 130 lining the coil 121 and the corresponding stator pole electrically insulating the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com