Laminated toughened glass insulator and preparation method thereof

A glass insulator and glass technology, applied in inorganic insulators, insulators, suspension/strain insulators, etc., can solve the problem of high self-explosion rate of glass insulators, and achieve the effect of no capillary pores on the surface, hard and fine surface, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

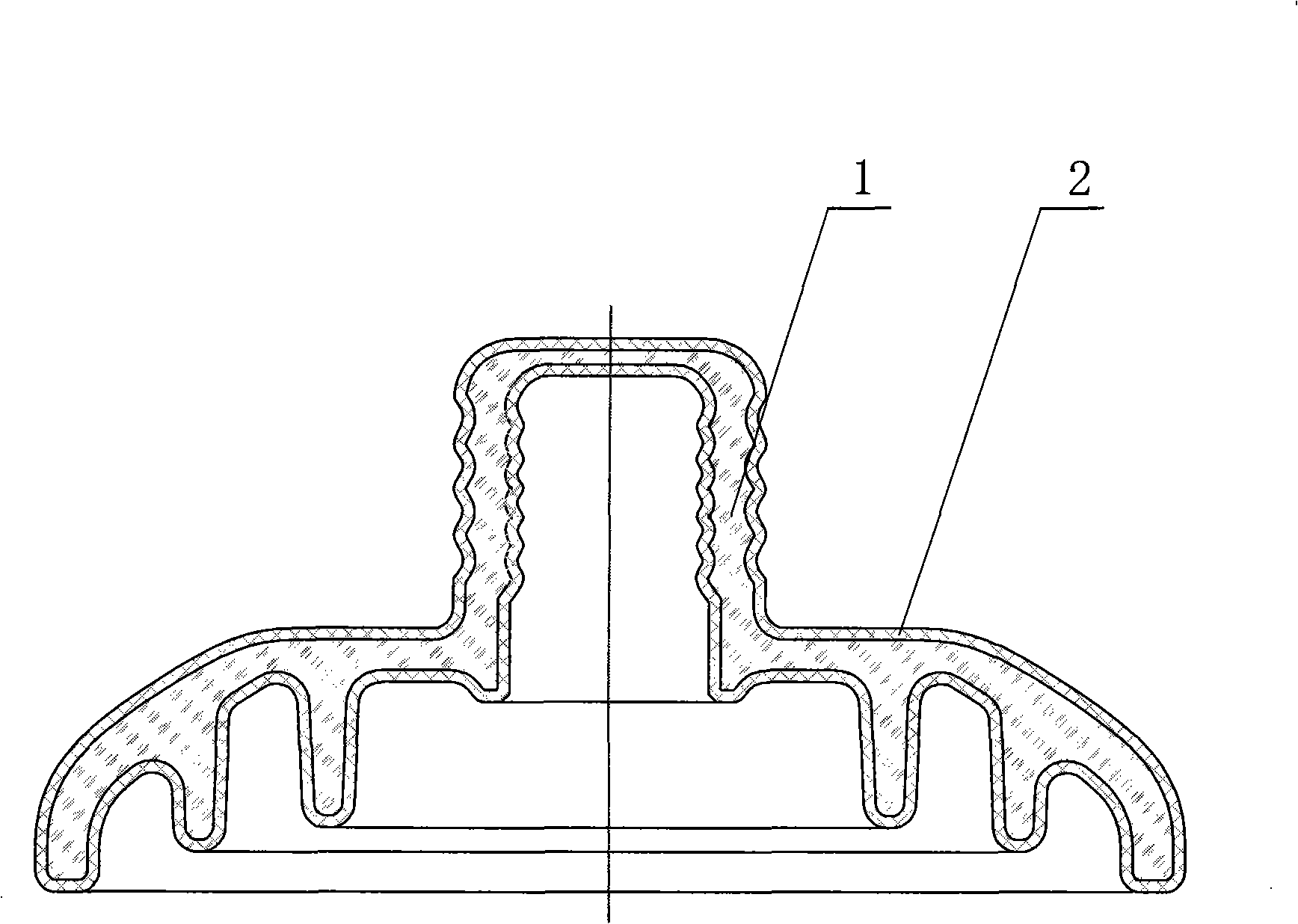

[0029] Centered on soda-lime glass 1 and wrapped with aluminosilicate glass 2 to prepare a laminated tempered glass insulator:

[0030] a), glass melting

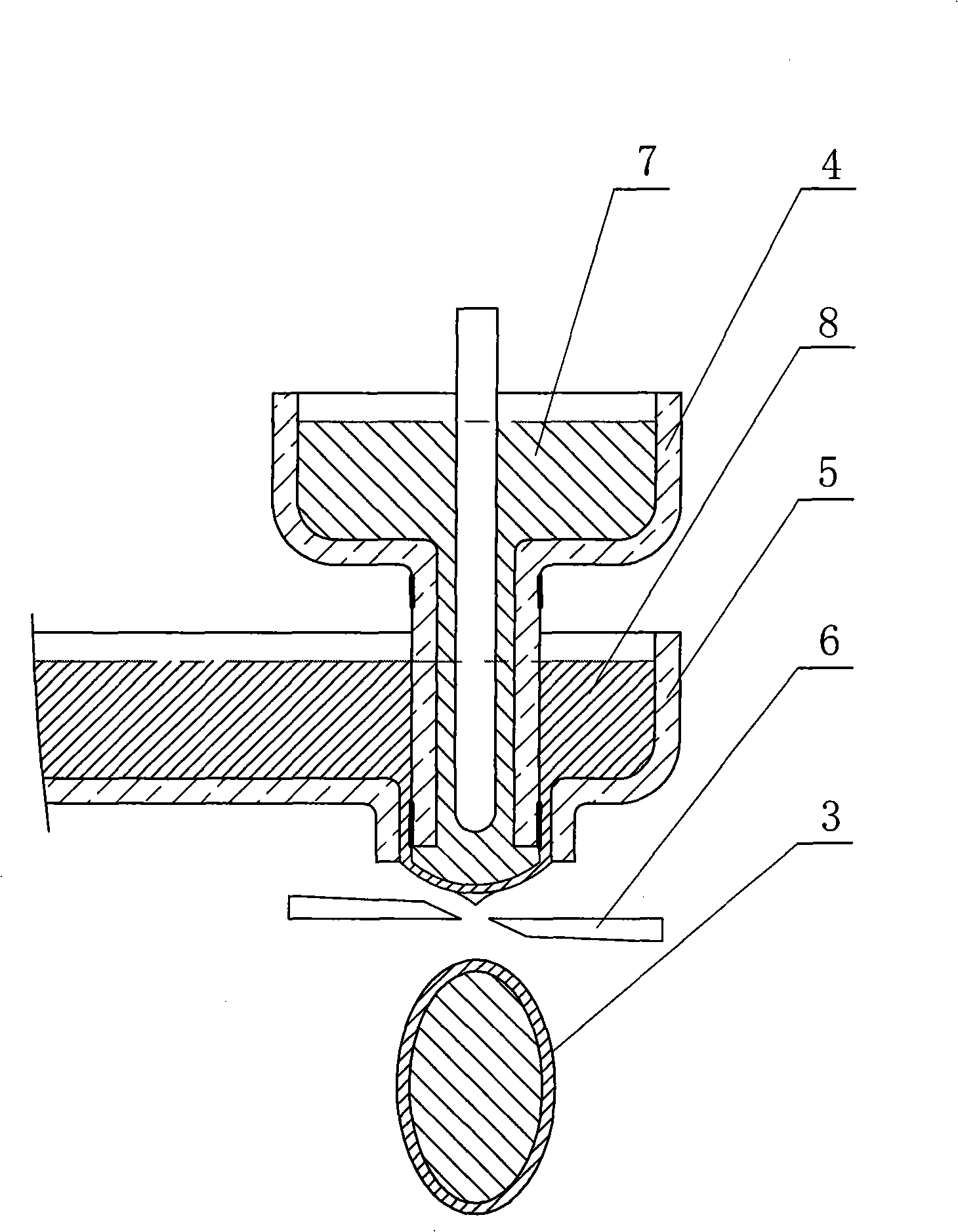

[0031] Put the glass raw material into the double-layer melting furnace. The upper layer 4 of the melting furnace melts the soda-lime glass liquid 7 with a melting temperature of 1500°C and the temperature of the forehearth is 1250°C; the lower layer of the melting furnace 5 melts the aluminum-silicate glass liquid 8 with a melting temperature of 1600°C Road temperature 1100.

[0032] b), making blank

[0033] The melted soda-lime glass 7 and aluminosilicate glass 8 pass through the outlet of the servo feeder, and are cut by scissors 6 to form a glass blank 3 with the soda-lime glass 7 in the center and the aluminosilicate glass 8 wrapped around it , the temperature of glass blank 3 is 1100°C.

[0034] c), forming

[0035] The glass blank 3 is placed in a molding machine to make a laminated glass insulator, and the mold...

Embodiment 2

[0039] A laminated tempered glass insulator is prepared by wrapping aluminosilicate glass 2 with white porcelain glass 1 as the center:

[0040] a), glass melting

[0041] Put the glass raw material into the double-layer melting furnace. The upper layer 4 of the melting furnace melts the white porcelain glass liquid 7 with a melting temperature of 1600°C and the temperature of the forehearth is 1100°C; The channel temperature is 1250°C.

[0042] b), making blank

[0043] The melted white porcelain glass liquid 7 and aluminosilicate glass liquid 8 pass through the outlet of the servo feeder, and are cut by scissors 6 to form a glass blank 3 with the white porcelain glass liquid 7 in the center and the aluminum silicon glass liquid 8 wrapped around it , the temperature of glass blank 3 is 900°C.

[0044] c), forming

[0045] Put the glass blank 3 into a molding machine to make a laminated glass insulator, and the molding temperature is 650°C.

[0046] d), tempering treatmen...

Embodiment 3

[0049] Laminated tempered glass insulators are prepared by wrapping low borosilicate glass 2 with soda-lime glass 1 as the center:

[0050] a), glass melting

[0051] Put the glass raw material into the double-layer melting furnace. The upper layer 4 of the melting furnace melts the soda-lime glass liquid 7 with a melting temperature of 1550°C and the temperature of the forehearth at 1200°C; the lower layer 5 of the melting furnace melts the low borosilicate glass liquid 8 with a melting temperature of 1600°C. The temperature of the forehearth is 1150°C.

[0052] b), making blank

[0053] The molten soda-lime glass 7 and the low-borosilicate glass 8 pass through the outlet of the servo feeder, and are cut by the scissors 6 to form a glass frit with the center of the soda-lime glass 7 and the outer wrapping of the low-borosilicate glass 8 Blank 3, the temperature of glass blank 3 is 1000°C.

[0054] c), molding

[0055] The glass blank 3 is placed in a molding machine to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com