Patents

Literature

49results about How to "Guaranteed installation position accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

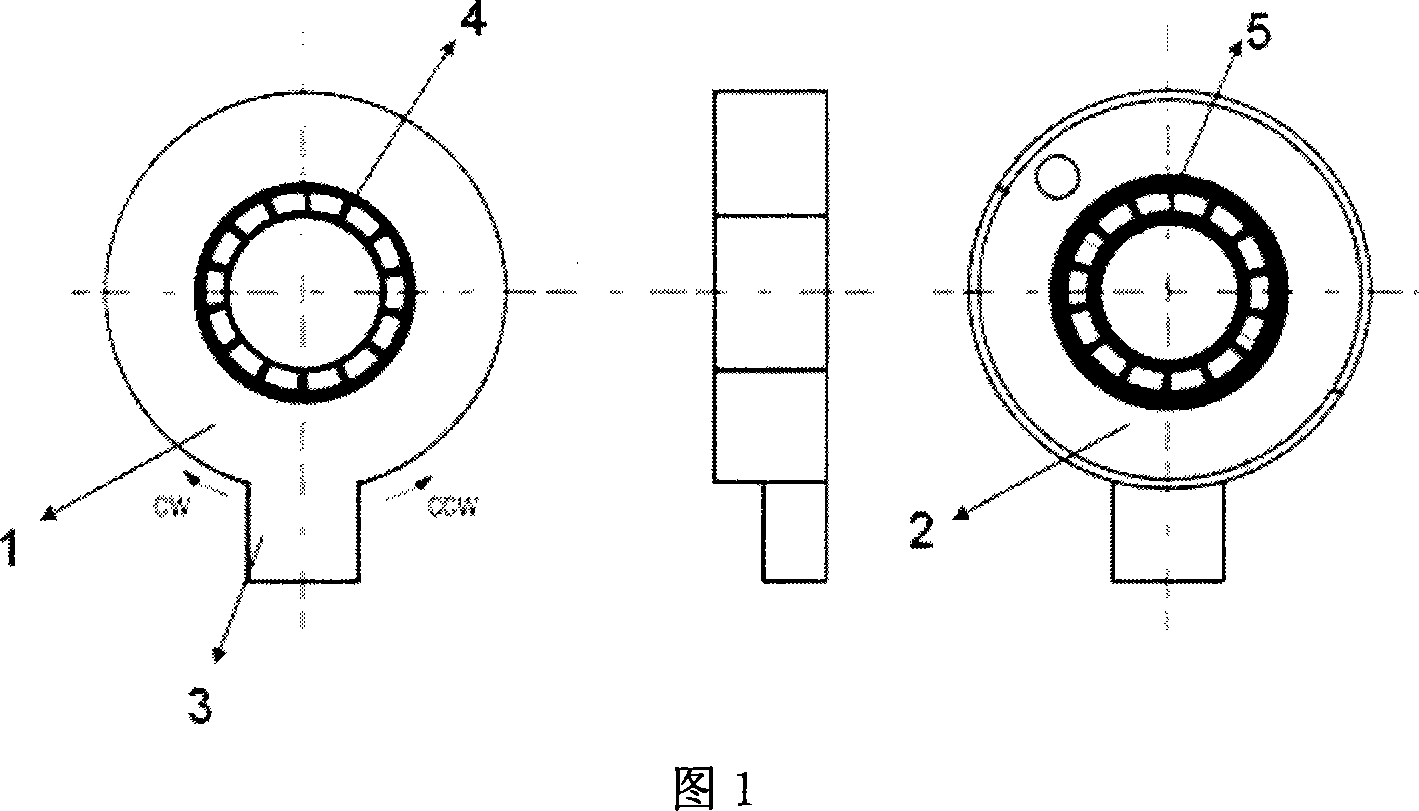

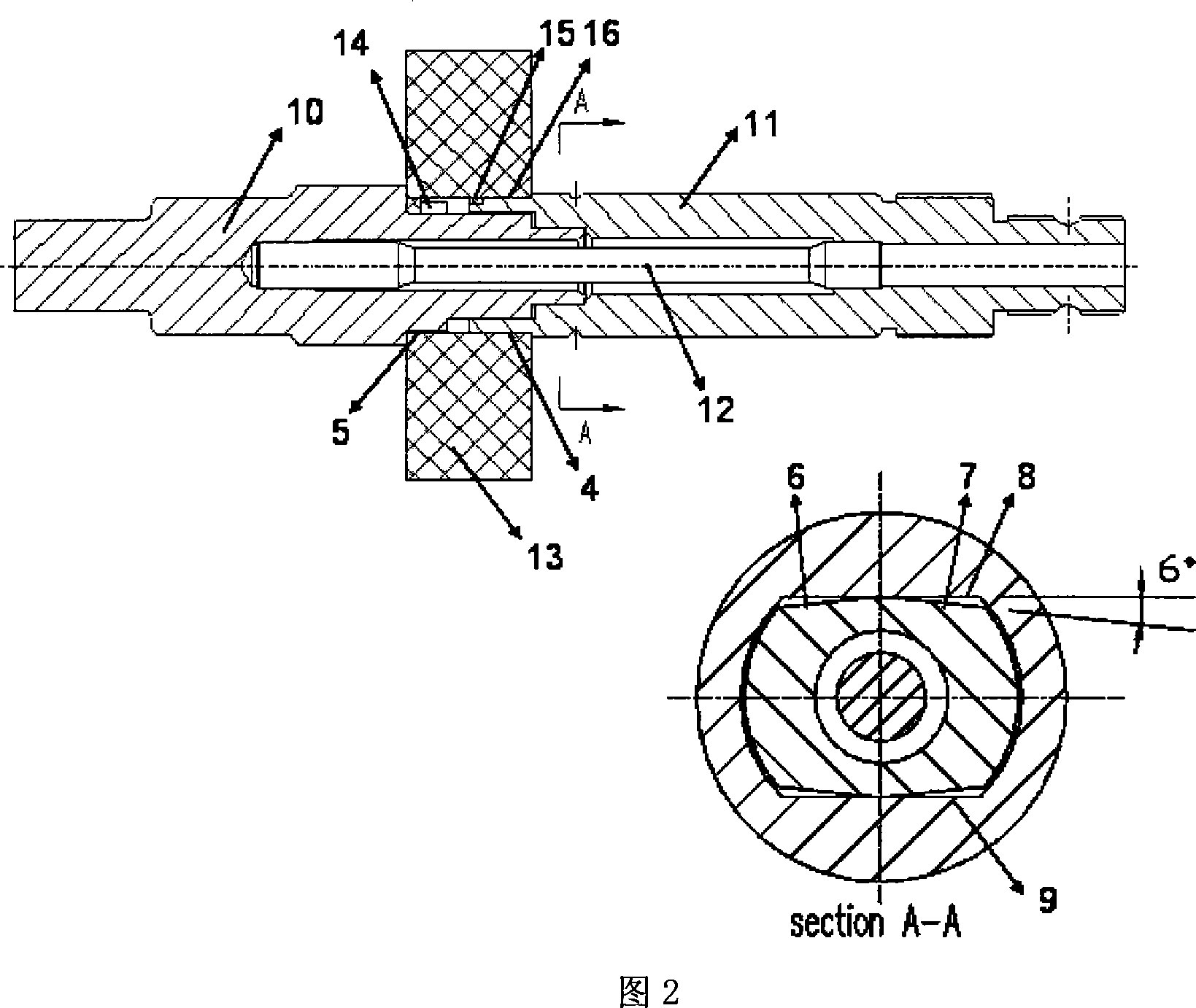

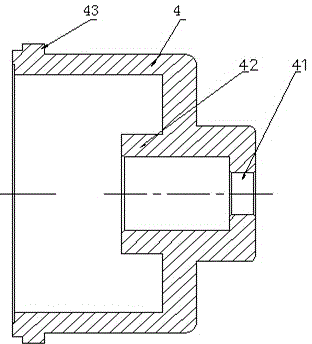

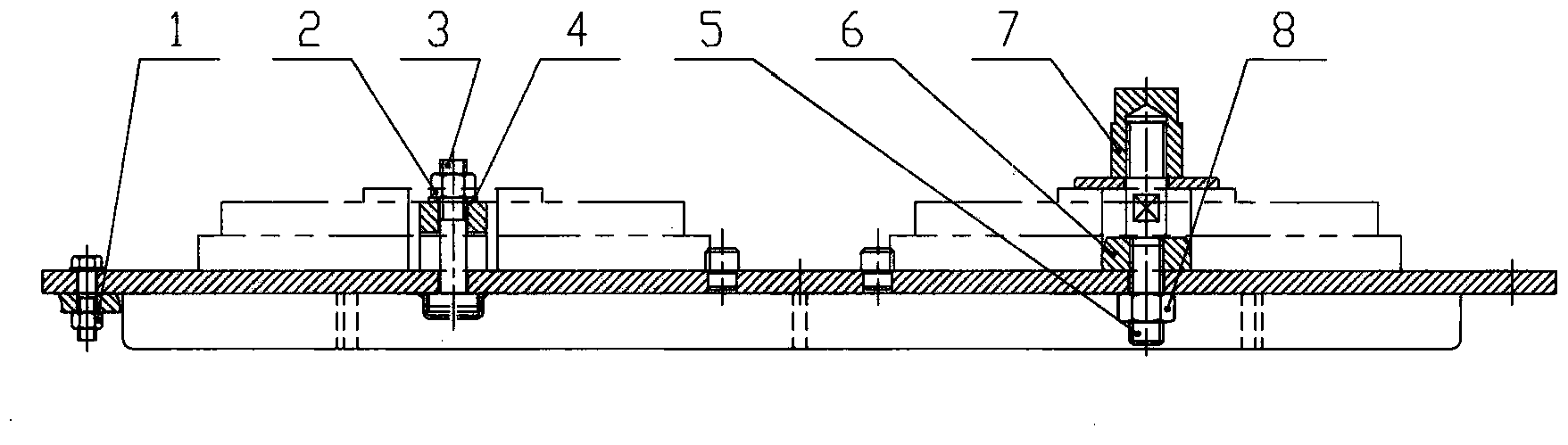

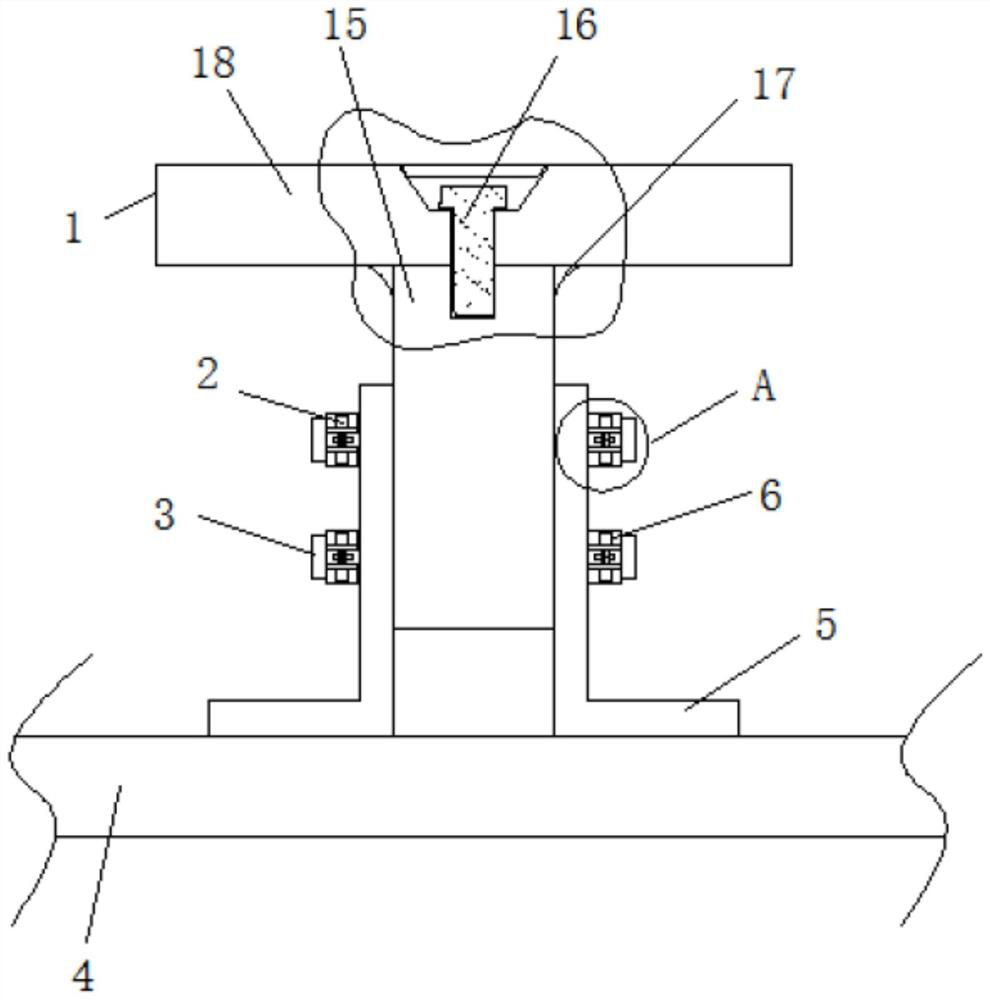

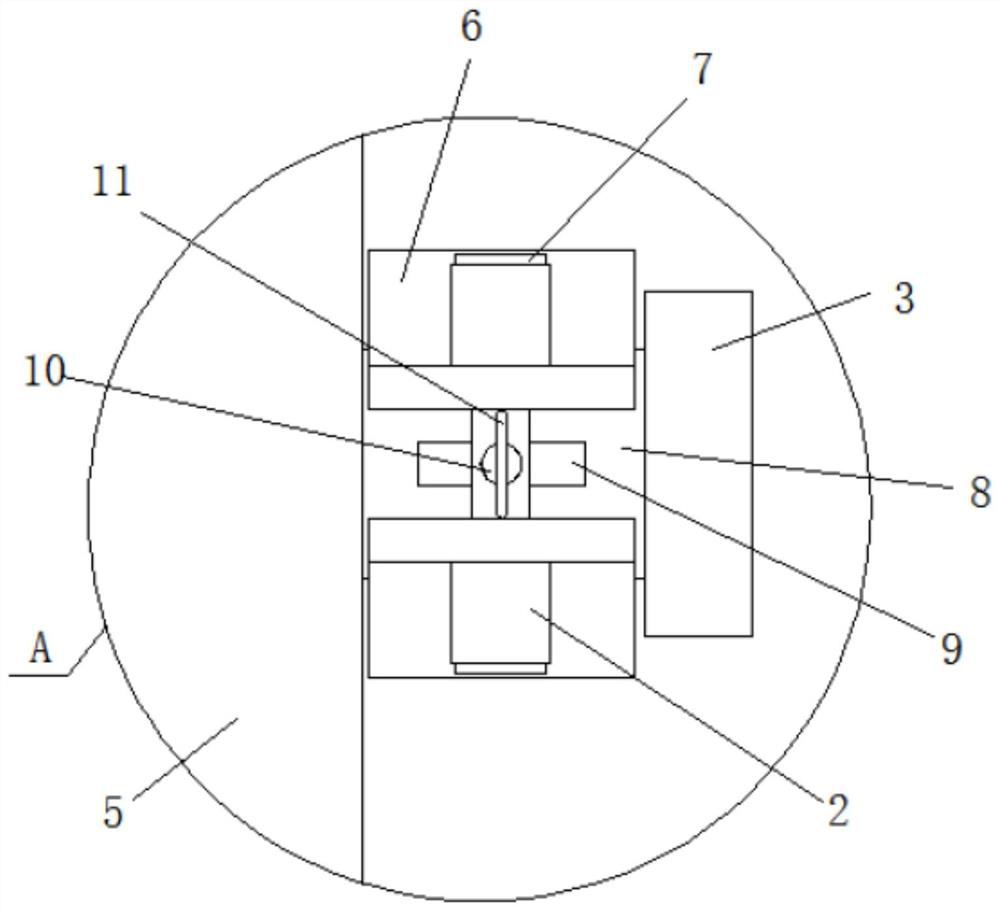

Steering shaft for electric boosting steering system

InactiveCN101054094AGuaranteed smoothnessGuaranteed stabilitySteering linkagesAutomatic steering controlElectric power steeringInterference fit

An electronic power-assisted steering system steering spindle, including input shaft 10, output shaft 11, torsion bar 12. Installation location and overload protection functions can be realized for torque rotation angle compound sensor 13. The moment torsion rotor 5 of torque rotation angle sensor 13 matches the input shaft 10 by key 14, the sensor position rotor 4 matches the output shaft 11 by key 15, and the fitting surface 16 of output shaft 11 and sensor 13 is knurl roll. Both ends of torsion bar 12 respectively interference fits with the input shaft 10 and the output shaft 11 hole. Angle of input shaft 10 between the tip plane6 and the tip plane 7 which fit the output shaft 11 is 168 degree, and the tip is the central symmetry shape. Output shaft 11 fits output shaft 10 are plane 8, plane 9.

Owner:SHANGHAI SHENZHOU VEHICLE RES & DEV

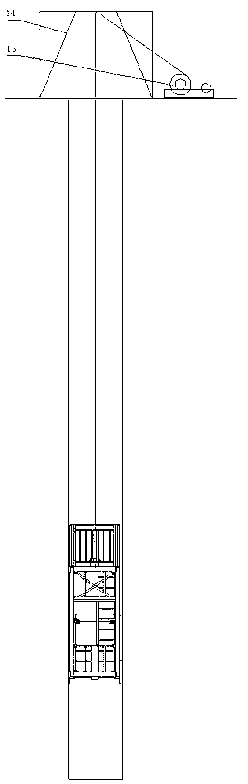

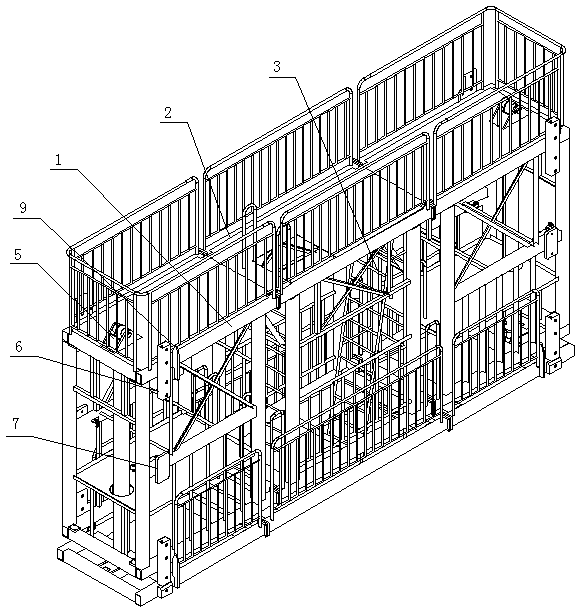

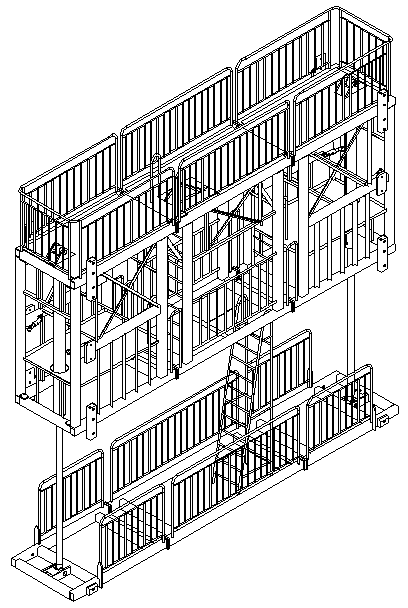

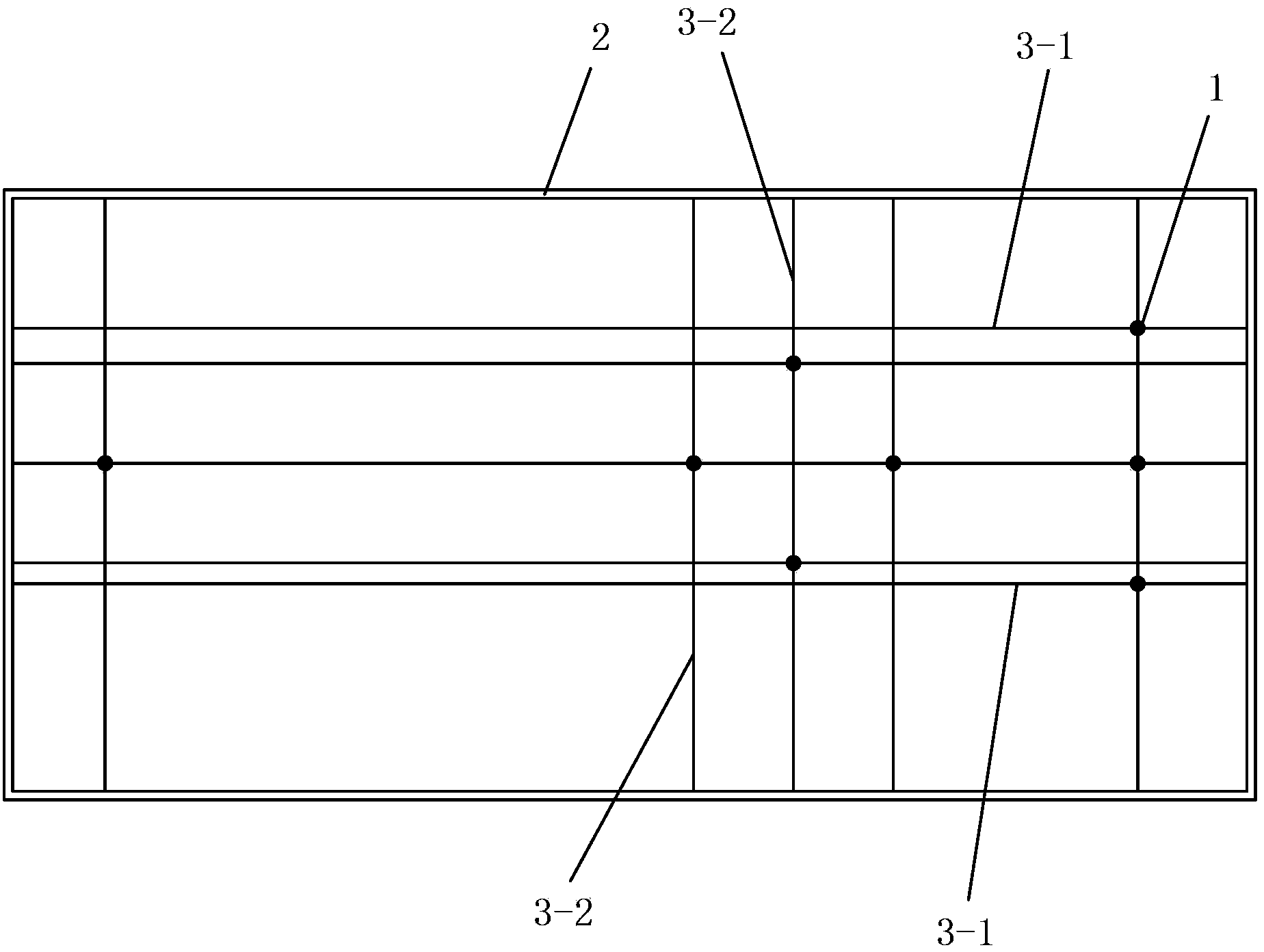

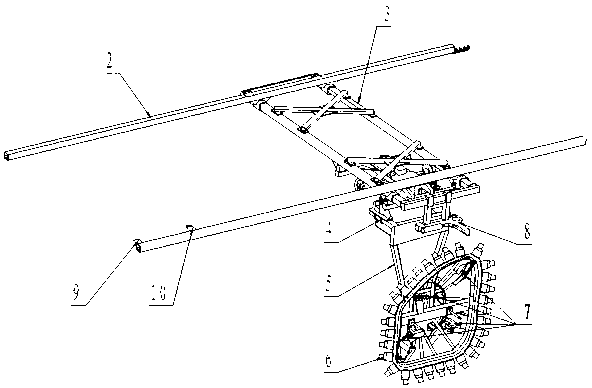

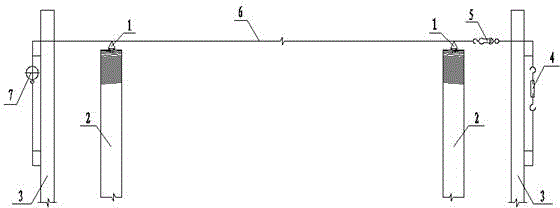

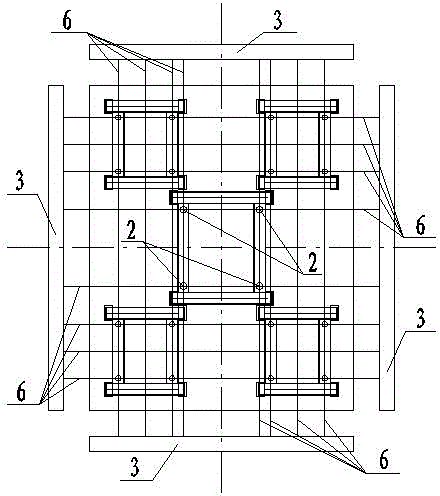

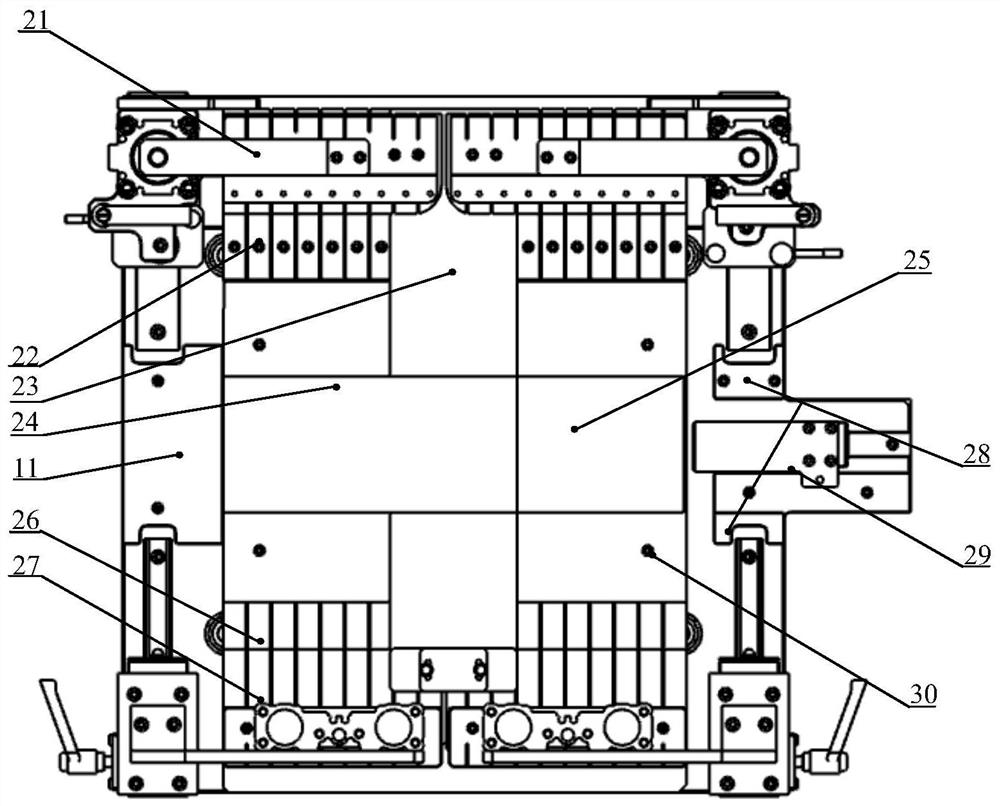

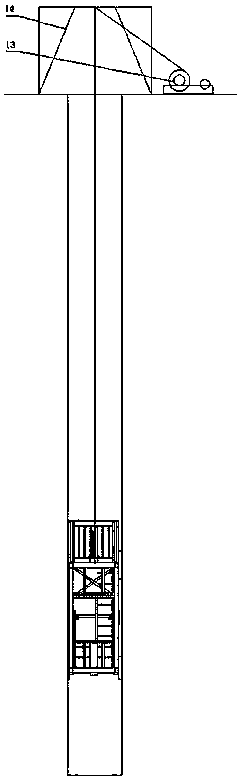

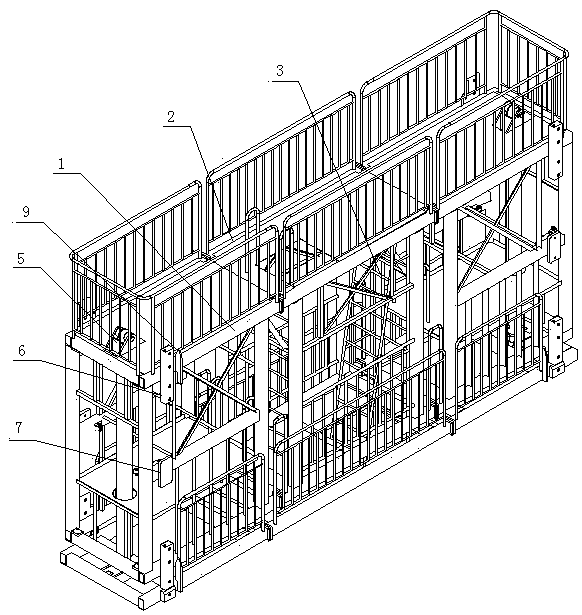

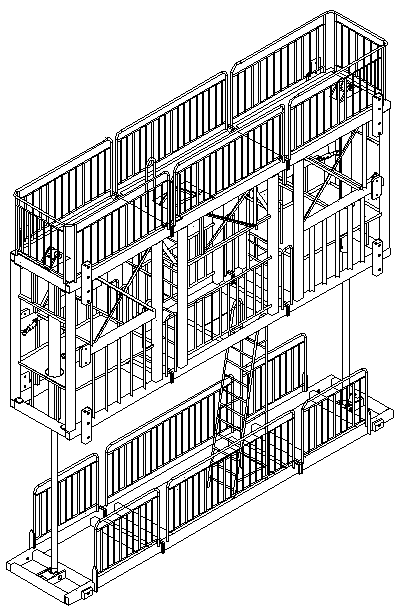

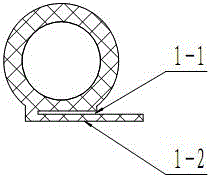

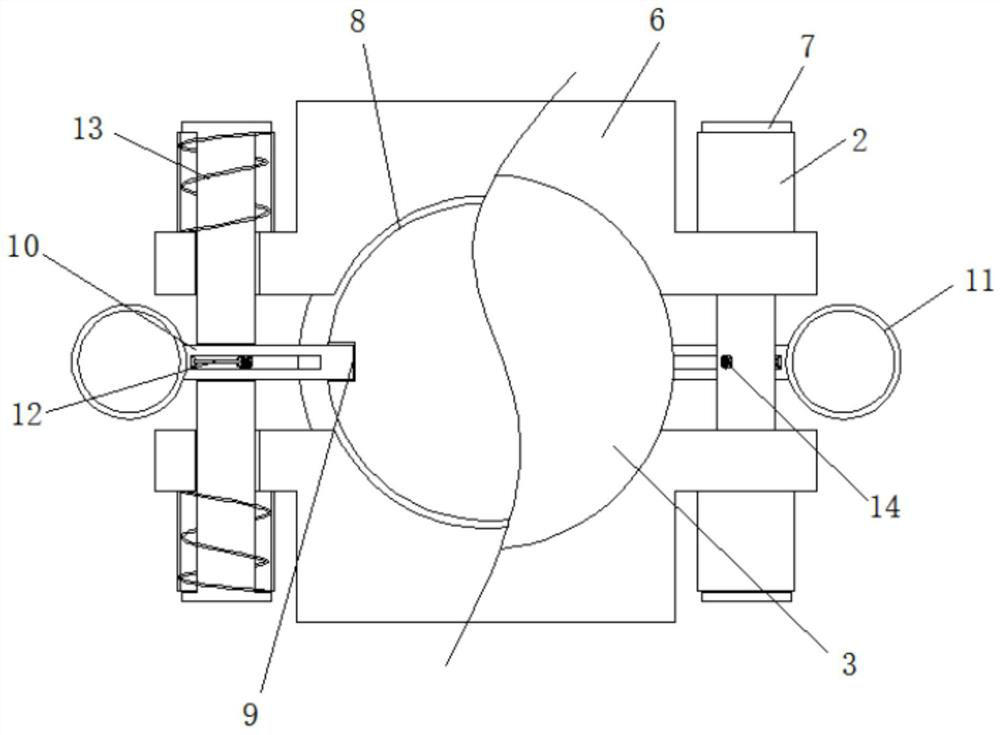

Gate slot construction method and device for gate

ActiveCN103074872AGuaranteed installation position accuracyGuaranteed accuracyBarrages/weirsWater-power plantsMechanical engineeringOpen air

The invention designs a gate slot construction device, which is used for realizing rapid gate slot construction of a gate by adopting a mechanical process. The device is provided with a gate slot positioning and clamping mechanism and a steel template, wherein left and right side members of each section of gate slot are connected with a climbing mechanism; after a gate slot is arranged, the lower end of the gate slot is kept fixed; a gate slot pouring space is closed by using the steel template, and concrete is poured; and the gate slot climbing device climbs by one section after one layer of concrete is poured every time. A truss structure in a novel gate slot construction device for the gate has the characteristics of high overall rigidity, high reliability and generality in a certain size range, so that the conventional open air dangerous operation way is turned into a way which is centered by highly mechanical assembly operation and assisted by manual operation, the construction safety and quality of a gate slot for a planar gate or an arc-shaped gate are guaranteed easily, and maximization of an engineering economic value is realized through a rapid construction way.

Owner:CHENGDU ALANGTECH

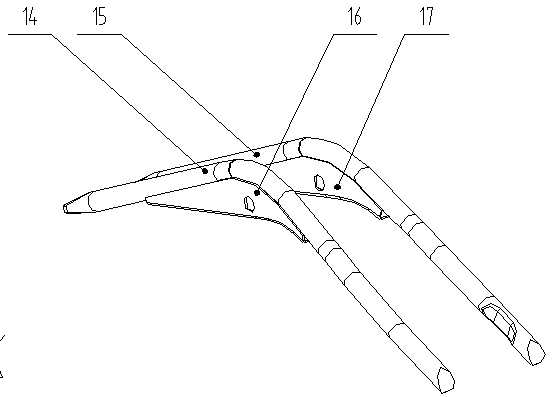

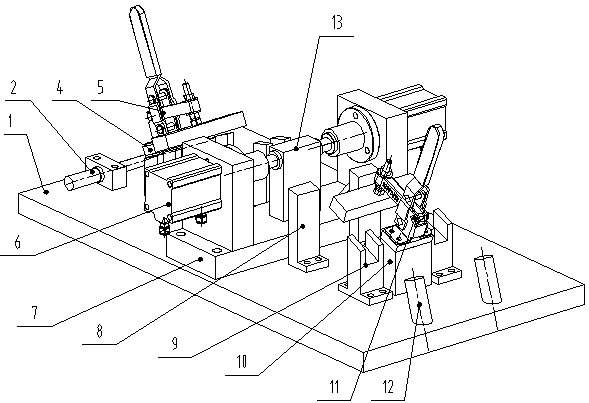

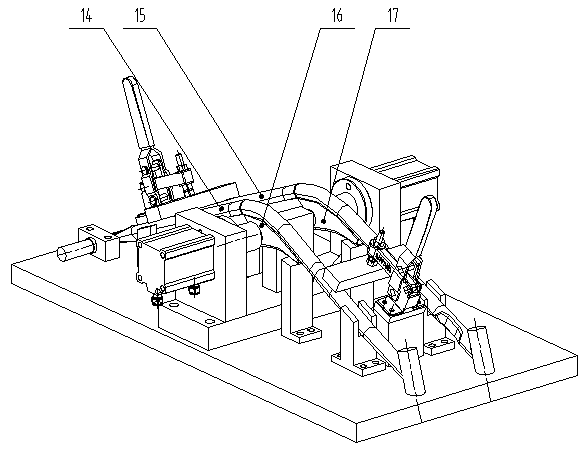

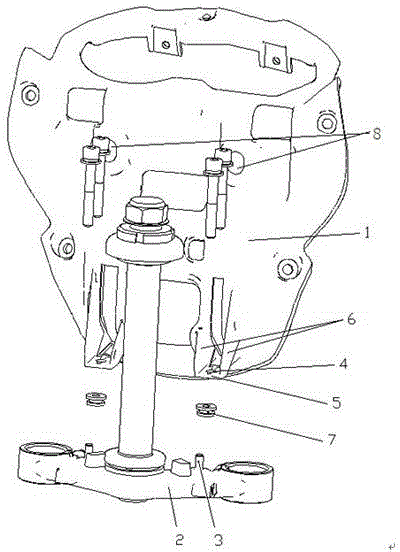

Ride-type motorcycle tail pipe assembly processing clamp and processing method thereof

InactiveCN103192216AGuaranteed positioning accuracyHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameDamper

The invention discloses a ride-type motorcycle tail pipe assembly processing clamp and a processing method thereof. The ride-type motorcycle tail pipe assembly processing clamp comprises a base plate, a damping-box fixing seat, a damping-box limiting seat, a cylinder, a tail pipe clamping groove, a tail-pipe end-face fixing pin, a tail pipe limiting pin, a rapid pressing clamp and the like structures which are arranged on the base plate. In the processing method, by the aid of the ride-type motorcycle tail pipe assembly processing clamp, the tail pipe and the damping box are positioned and then are mechanically welded to be integrated to be connected to a motorcycle frame; and positioning accuracy is improved, welding quality is improved by adopting the mechanically weld, connecting strength and positioning accuracy of the damping box are improved accordingly, and mounting quality of the damper is improved. The ride-type motorcycle tail pipe assembly processing clamp has the advantages of simple structure, reliable position, convenience in operation, low implementation cost and the like.

Owner:力帆科技(集团)股份有限公司

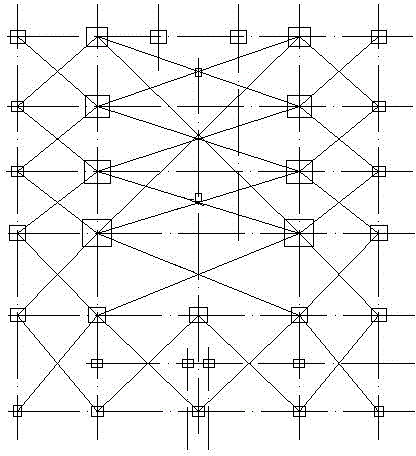

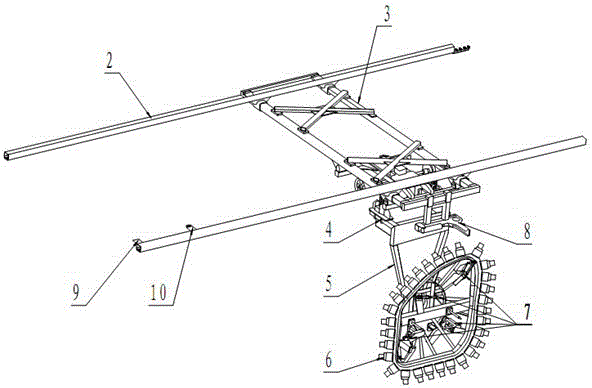

Method for manufacturing roofing truss

The invention discloses a method for manufacturing roofing truss. The truss is constructed by truss nodes which are formed by assembling truss members by welding. The manufacturing steps are: decomposing an integral truss into the truss members in a computer, and manufacturing the truss members; manufacturing a bed-jig for assembling by welding; locating an upper chord, a lower chord and a taper transition section on the bed-jig, hoisting and locating brackets of sub-trusses and welding; hoisting and locating brackets of straight web members and welding; hoisting and locating brackets of slant web members, welding and measuring; hoisting and locating drawing plates, mounting stiffening plate, and welding; re-hoisting to the bed-jig for measuring and calibrating; marking out residual lines at the end parts and butting; and integrally assembly. The upper chord and lower chord in the invention adopts integral manufacturing, dispenses with intermediate inlaying web member, thus shortening distance between the upper chord and the lower chord, reducing assembly area and improving processing efficiency; the computer is adopted to collect coordinate data, thus ensuring preciseness of mounting and locating, reducing working hours, and increasing economic benefit.

Owner:JIANGSU HUNING STEEL MECHANISM

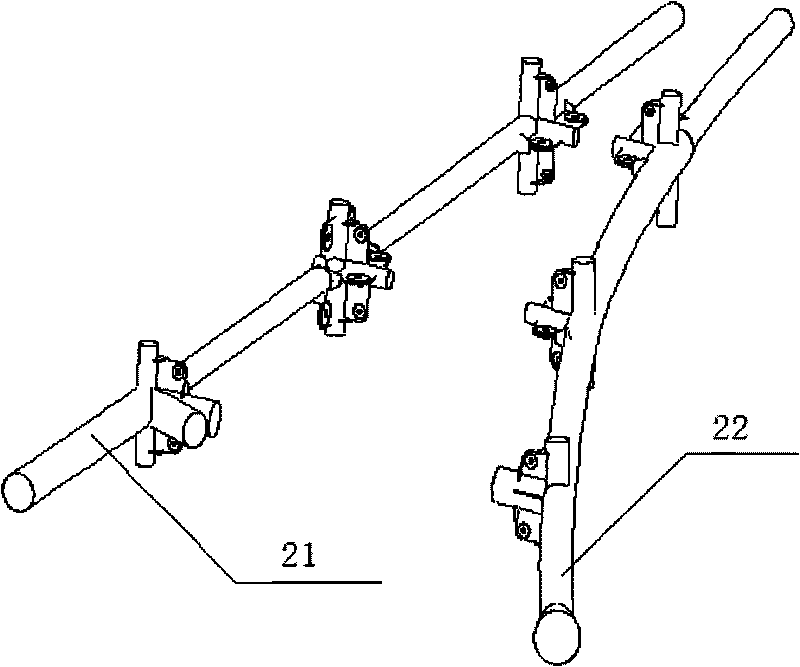

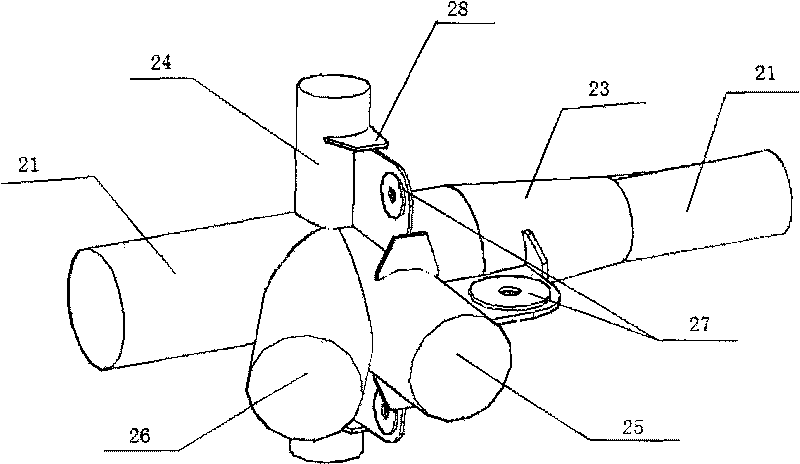

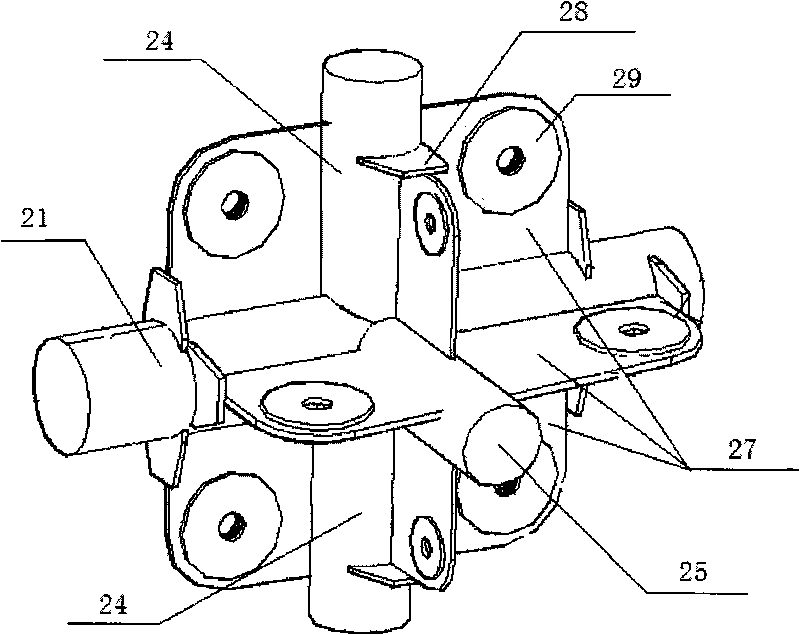

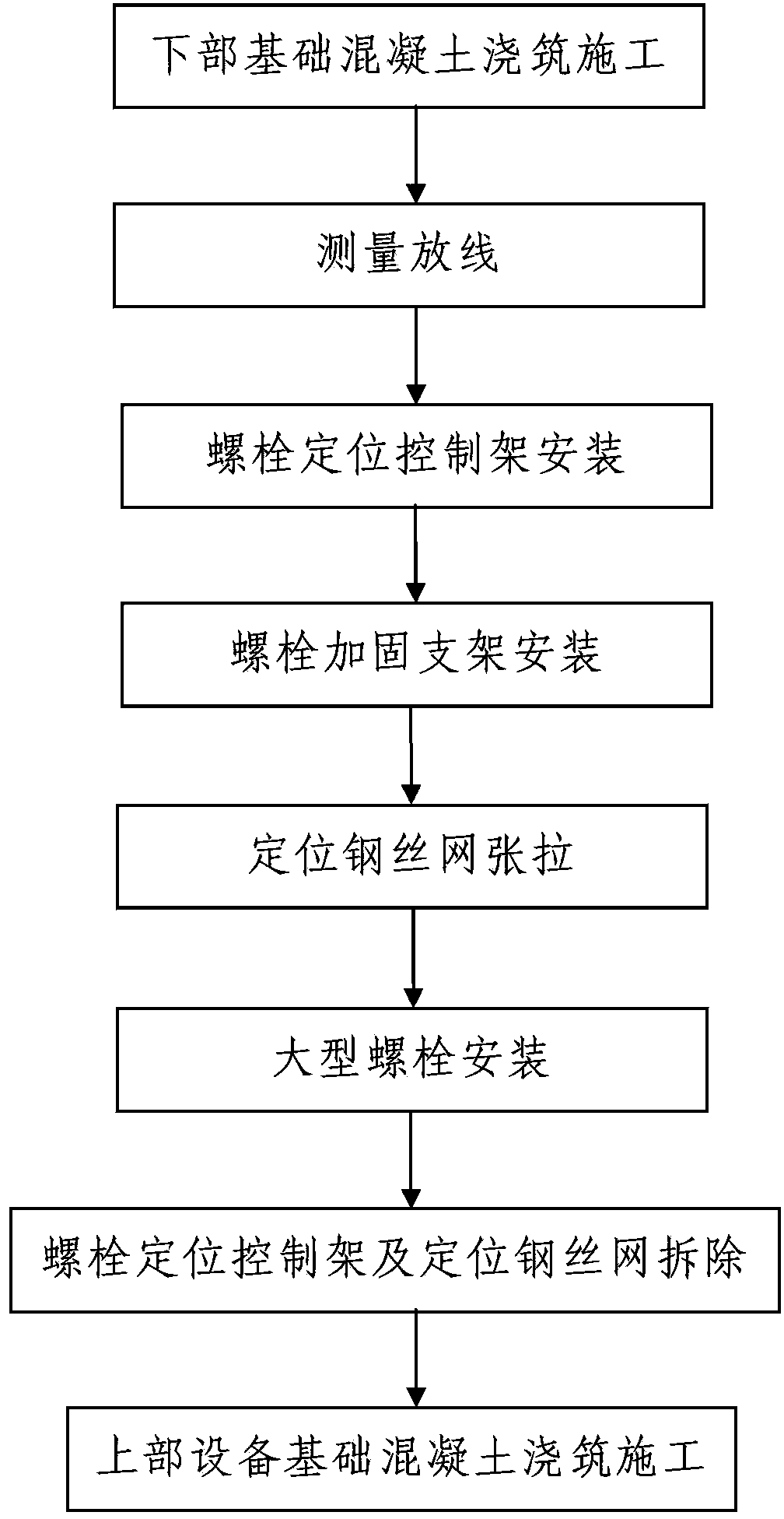

Large-scale bolt high-precision pre-burying construction method

ActiveCN103352476ASimple structureReasonable designFoundation engineeringCushionBuilding construction

The invention discloses a large-scale bolt high-precision pre-burying construction method. The number of pre-buried large-scale bolts is N, all the large-scale bolts are pre-buried in a construction device foundation, the large-scale bolts comprise screw rods and bases, external threads are arranged at the top ends of the screw rods, the bases are arranged on the bottom portions of the screw rods, and the device foundation is divided into a lower foundation cushion layer and an upper device foundation with the plane where the bottom portions of the bases of the large-scale bolts are located as a boundary. The method comprises a first step of carrying out concrete pouring construction on the lower foundation cushion layer, a second step of carrying out measurement and paying off, a third step of mounting a bolt locating control rack, a fourth step of mounting a bolt reinforcing support, a fifth step of tensioning a locating steel wire net, a sixth step of mounting the large-scale bolts, a seventh step of removing the bolt locating control rack and the locating steel wire net, and an eighth step of carrying out concrete pouring construction on the upper device foundation. The method is simple in process, reasonable in design, convenient to achieve, good in using effect, and capable of simply, conveniently and fast achieving the high-precision pre-burying process of the large-scale bolts in the device foundation in high quality.

Owner:陕西建工第十一建设集团有限公司

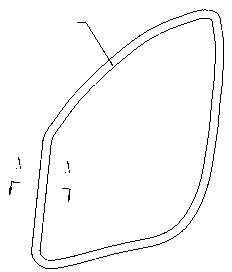

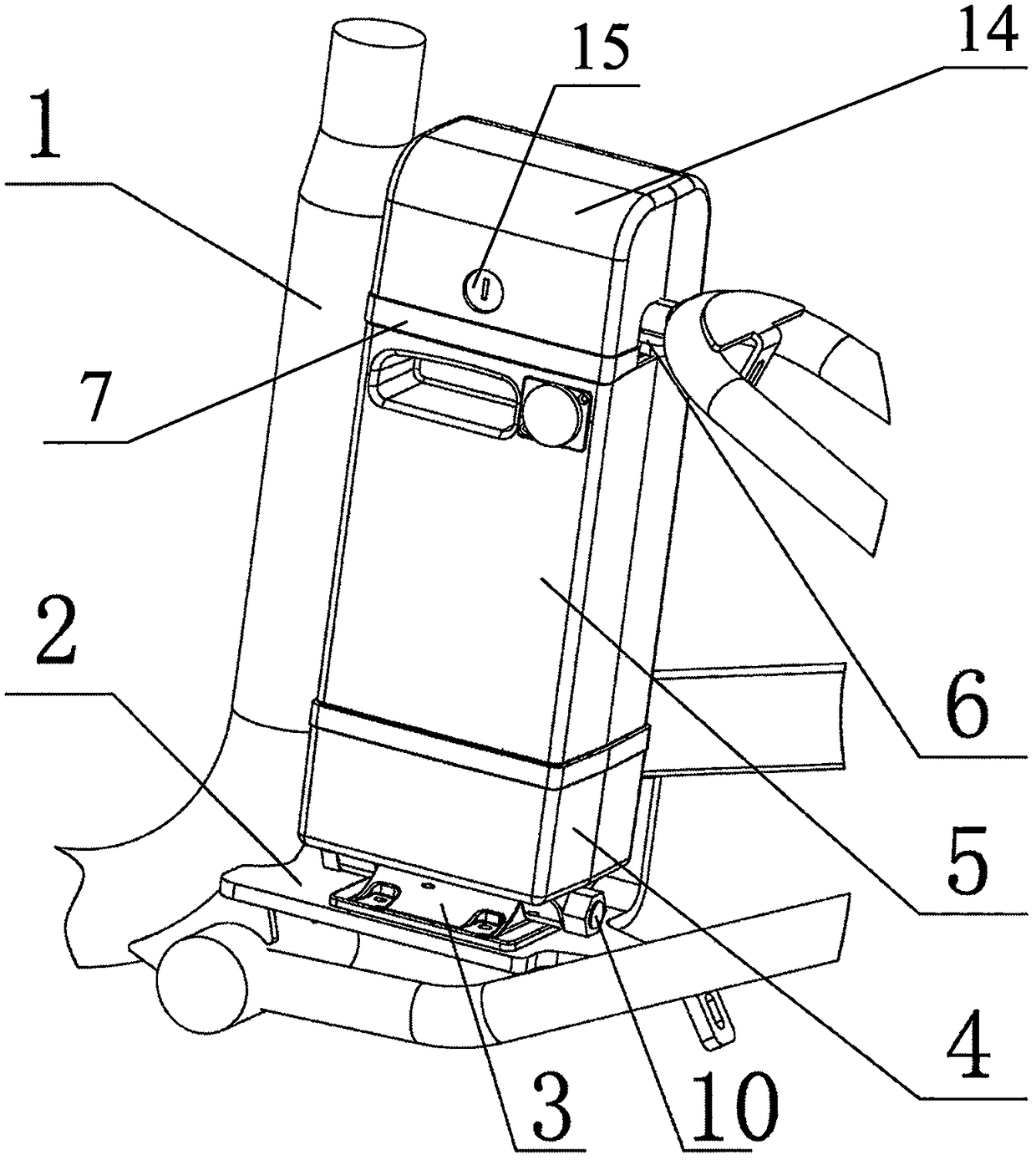

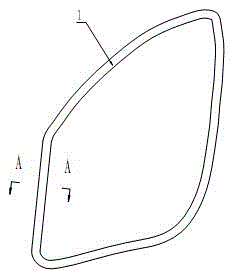

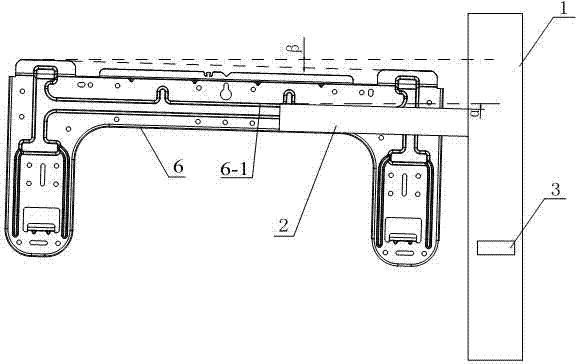

Installation device for auto door seal strip of automobile

An installation device for an auto door seal strip of an automobile is used for solving installation problems of an integral 3M glue-bonding seal strip. The installation device for the auto door seal strip of the automobile comprises a fixed sliding rail, a horizontal-moving sliding rail, a sliding trolley, and a profiling frame. The fixed sliding rail is composed of two longitudinal rails. The horizontal-moving sliding rail is horizontally arranged and is assembled with the fixed sliding rail. The sliding trolley is assembled with the horizontal-moving sliding rail. The profiling frame is hung below the sliding trolley. The outline of the profiling frame is matched with a door fame. A pressing mechanism is arranged on the outer side of the profiling frame in the circumferential direction. The pressing mechanism is composed of a set of pressing units which are closely arranged. According to the installation device for the auto door seal strip of the automobile, a seal strip is prevented from being drawn in an installation process, distortion of the seal strip when the seal strip is bonded is eliminated, precision of the installation and positioning of the seal strip is guaranteed, and assembly quality of the seal strip is improved.

Owner:长城汽车股份有限公司平湖分公司

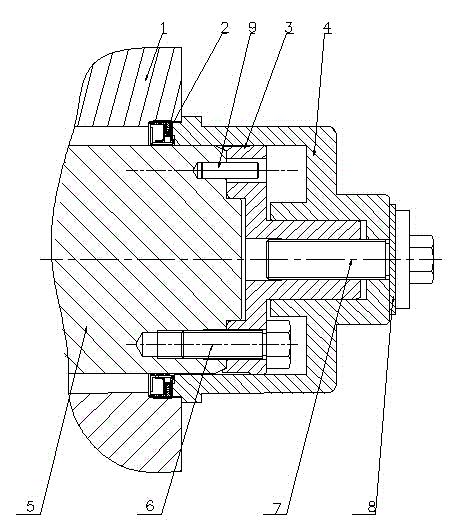

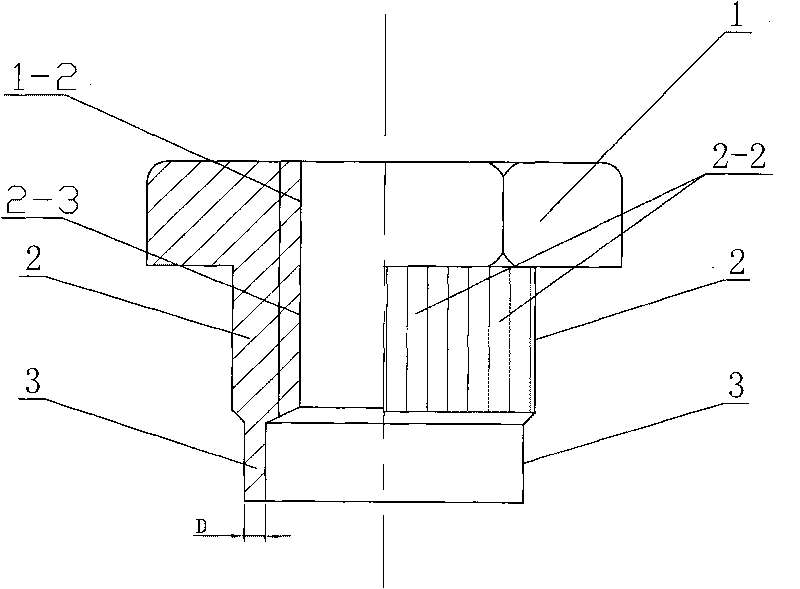

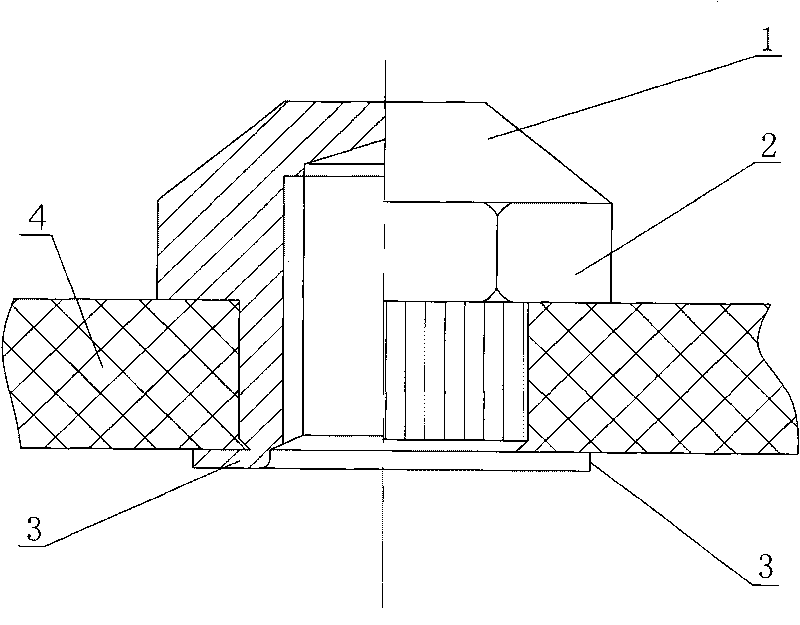

Device for installing crank shaft rear oil seal

InactiveCN104552144AAvoid oil spill hazardsGuaranteed installation position and installation accuracyMetal-working hand toolsLubricationCrankshaft

The invention relates to the technical field of oil seal installation, and specifically relates to a device for installing crank shaft rear oil seal; the device comprises a connecting disk, a sliding gland which is sleeved outside the connecting disk and in slide fit with the connecting disk, and a compressing nut which is matched with a screw hole in the connecting disk after penetrating the sliding gland. In the device for installing crank shaft rear oil seal, the sliding gland acts on the rear oil seal via the connecting disk, thus makes the rear oil seal be uniformly stressed and coaxially guided into the crank shaft end in parallel, thereby guaranteeing the precision of the installation, being able to effectively avoiding the hidden trouble of oil leakage caused by that the rear oil seal is not uniformly stressed during the installation process; additionally, by arranging a limit protrusion on the sliding gland, the depth of installing the oil seal can be determined as needed, thus ensuring the installation position and the installation precision of the oil seal; the device for installing crank shaft rear oil seal is simple, practical, convenient, and simple in installation process, thereby effectively preventing lubrication oil leakage caused by inclined installation and unfulfilled installation or excessive installation of the oil seal.

Owner:SINOTRUK JINAN FUQIANG POWER

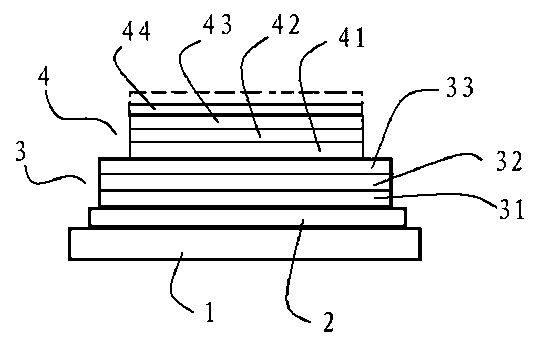

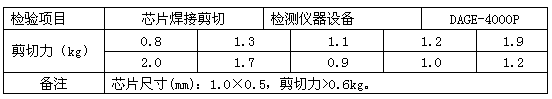

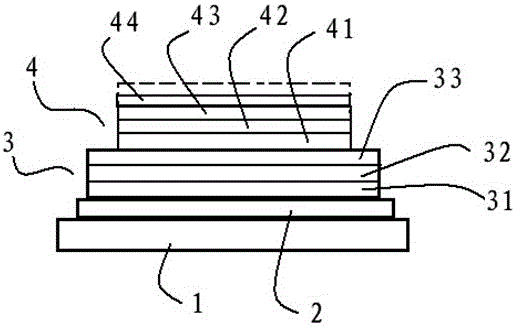

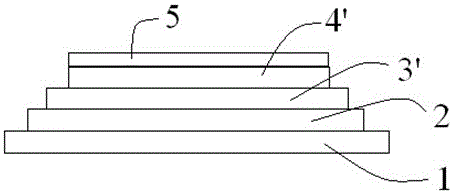

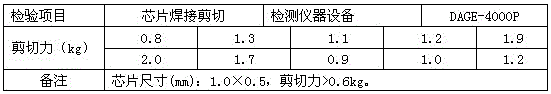

Welding substrate for electronic product and manufacturing method of welding substrate

ActiveCN103227161AGraphical lines with high precisionHigh precisionSemiconductor/solid-state device detailsSolid-state devicesAlloyGold layer

The invention discloses a welding substrate for an electronic product. The welding substrate comprises a base plate, wherein the base plate is provided with a metallized graph layer, the metallized graph layer is provided with a gold-tin film layer, a barrier layer is arranged between the gold-tin film layer and the metallized graph layer and is a single metal film layer or a composite metal film layer, and the gold-tin film layer is a gold-tin alloy layer or is of a multi-layer structure formed by alternately compounding gold layers and tin layers. With the adoption of the film substrate, the graph line accuracy is high, the surface smoothness of the film layer is good, a chip can be directly welded and located without needing to precasting solders, the installation and locating accuracy of the chip can be ensured, and the film substrate is suitable for photoelectric products of high-power LED (light-Emitting Diode) optical communication and the like. Meanwhile, according to the film substrate disclosed by the invention, the proper component proportion of gold and tin in the film substrate can be adopted according to different chips needed to be welded on the underlay film substrate, so that the welding performance of the chips is better.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

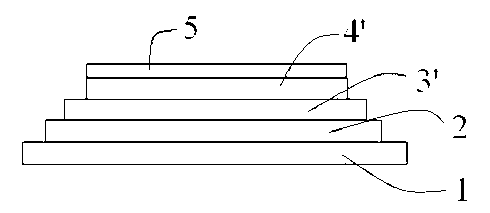

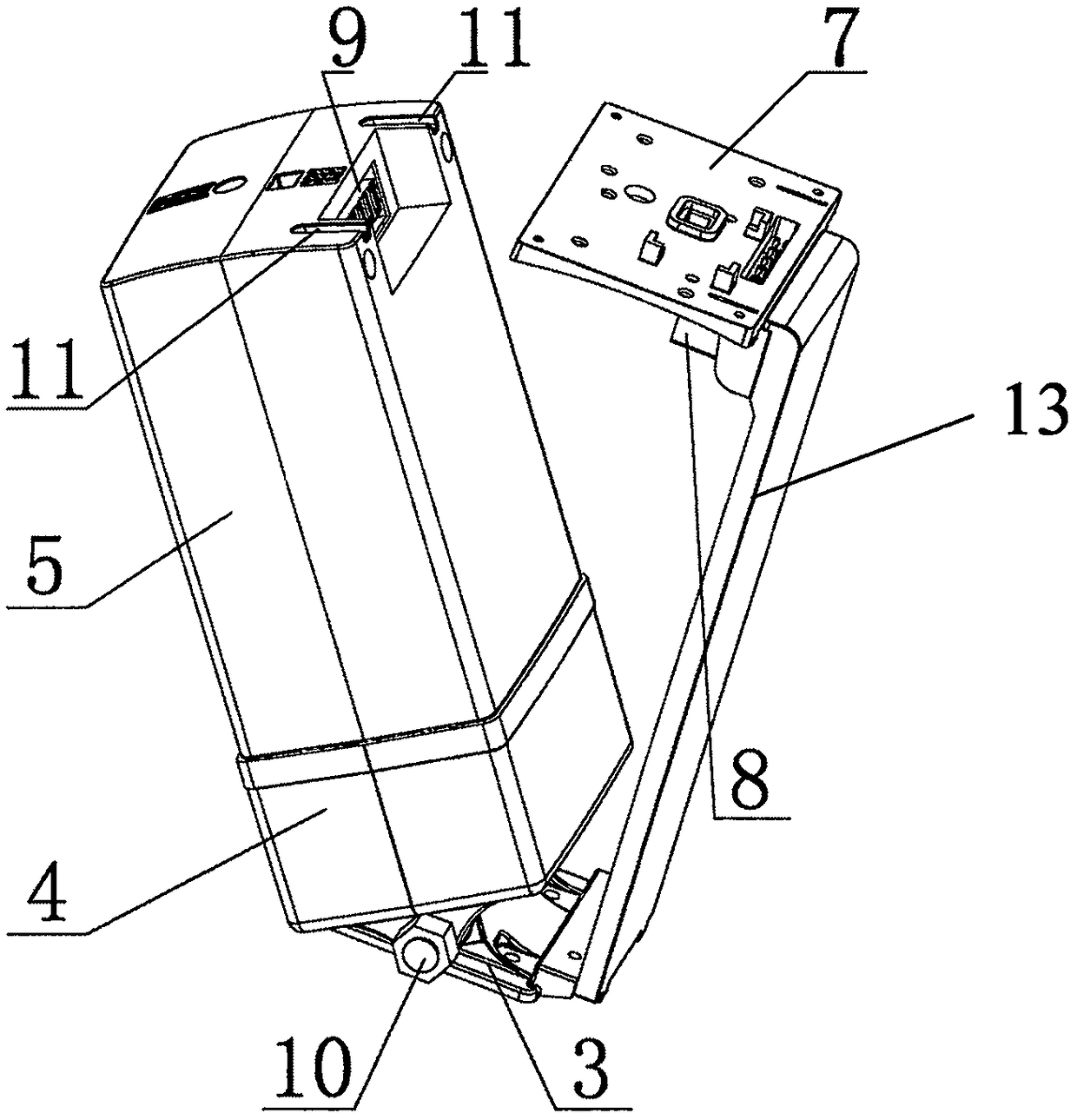

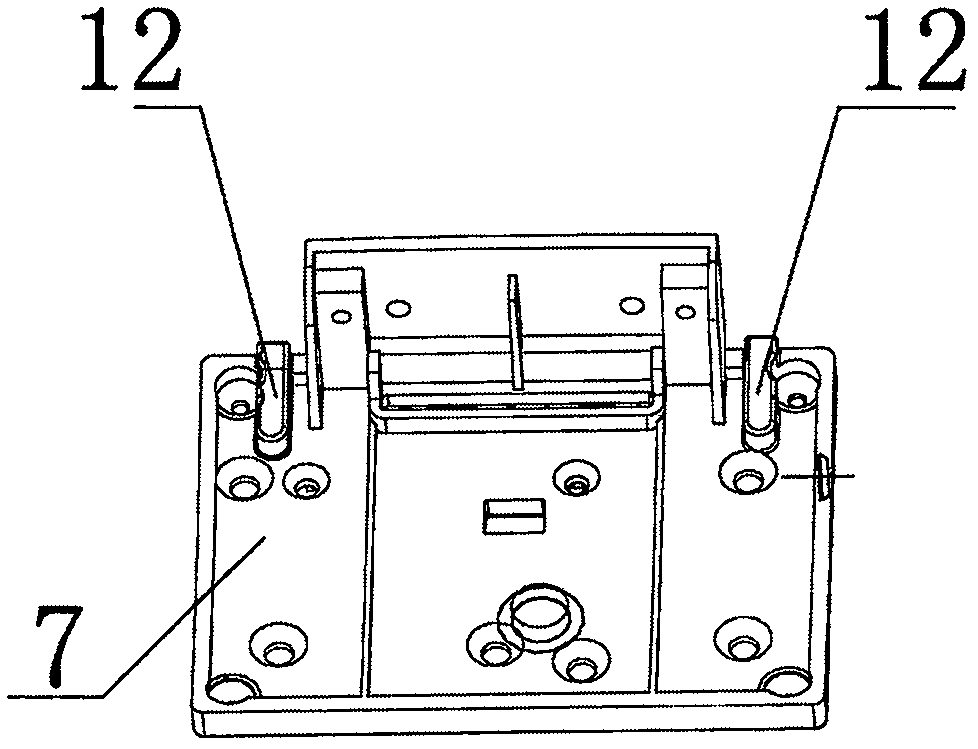

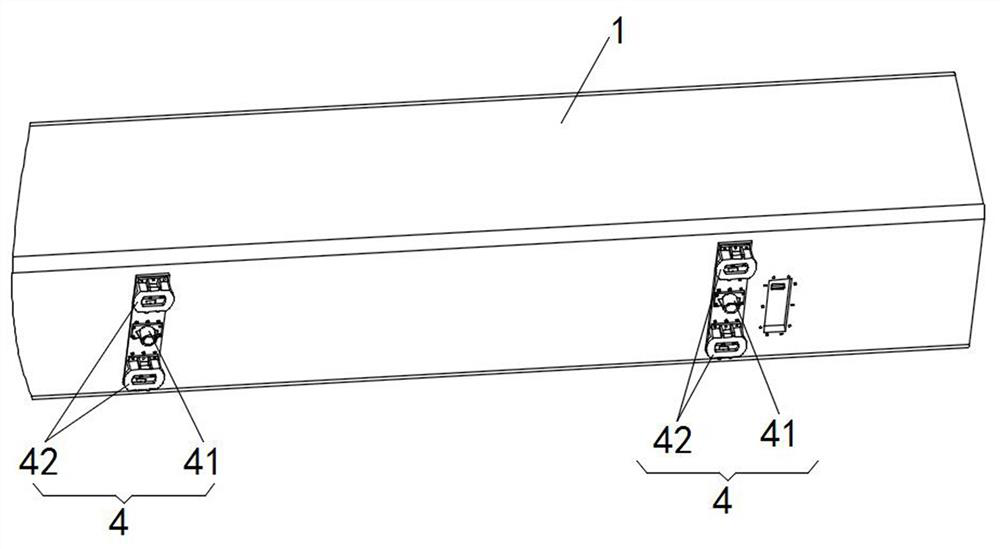

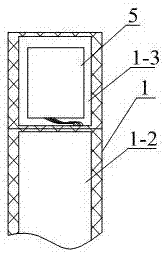

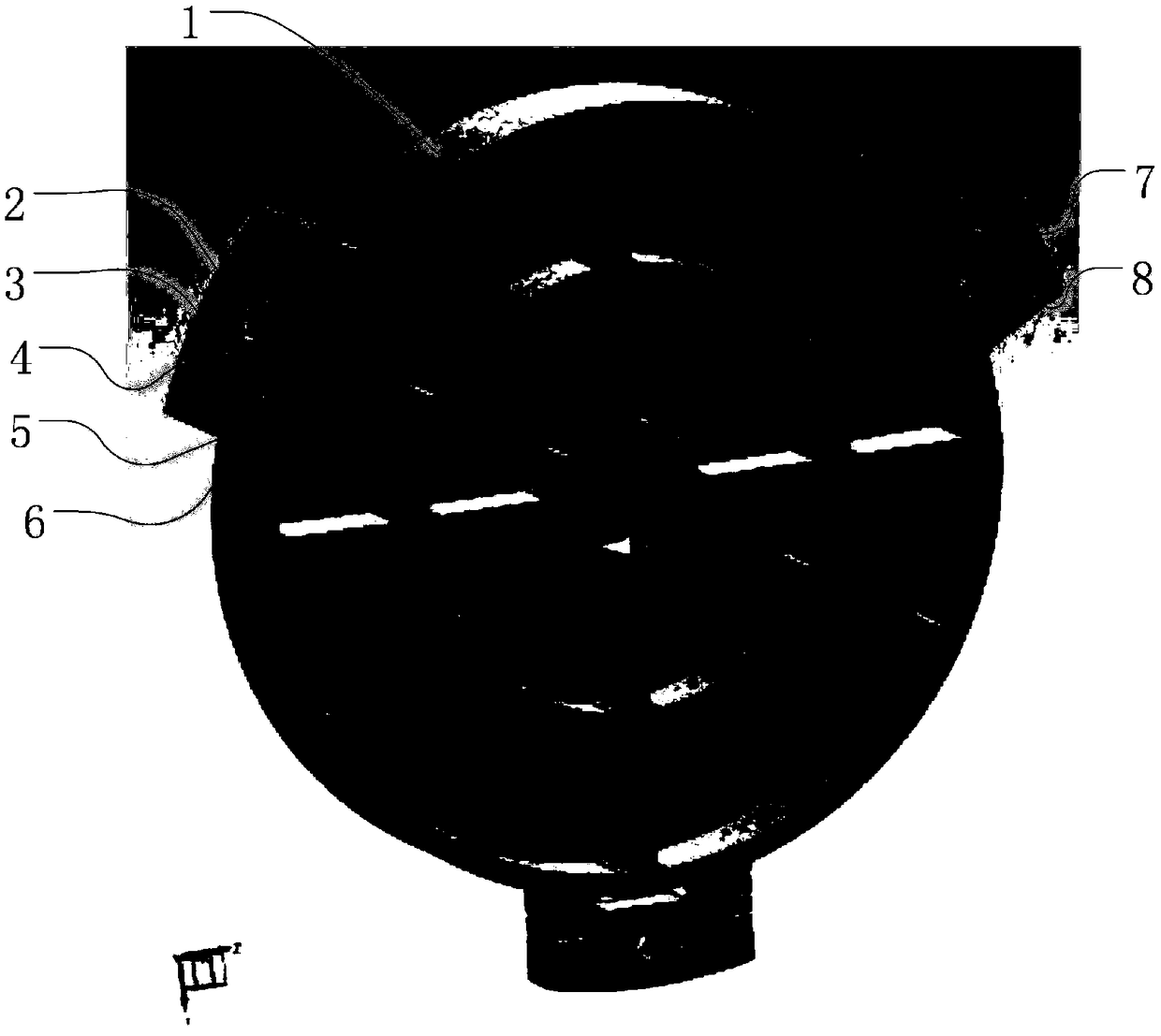

Mounting structure of laterally-placed battery box for electric bicycle

InactiveCN108357622AGuaranteed installation position accuracyReduce volumeRider propulsionEngineeringTroffer

The invention discloses a mounting structure of a laterally-placed battery box for an electric bicycle. The mounting structure comprises a bicycle middle tube, a battery box, a discharge male end anda discharge female end; a mounting plate is fixed at the rear upper portion of the bicycle middle tube, and a bottom plate is fixed at the rear lower portion of the bicycle middle tube; a rotating fixing seat is fixed to the bottom plate, a sleeve and the rotating fixing seat are hinged together through a rotating shaft which is arranged in the front-rear direction of travelling of the electric bicycle, and the battery box can be loaded into the sleeve; when the battery box is pushed, the battery box and the sleeve jointly take the rotating shaft as a rotation axis to fall towards the side face of the electric bicycle, an upper fixing plate is mounted on the lower portion of the mounting plate, the discharge male end is mounted on the lower rear portion of the upper fixing plate in the pushing-in direction of the battery box, and the discharge female end is mounted on the upper rear portion of the battery box; two grooves playing a guiding role are formed in the top end of the batterybox in the pushing-in direction of the battery box; and two protrusions playing the guiding role are arranged on the corresponding positions of the upper fixing plate. The mounting structure has the high waterproof and anti-creeping effects.

Owner:天津市万卓友和科技有限公司

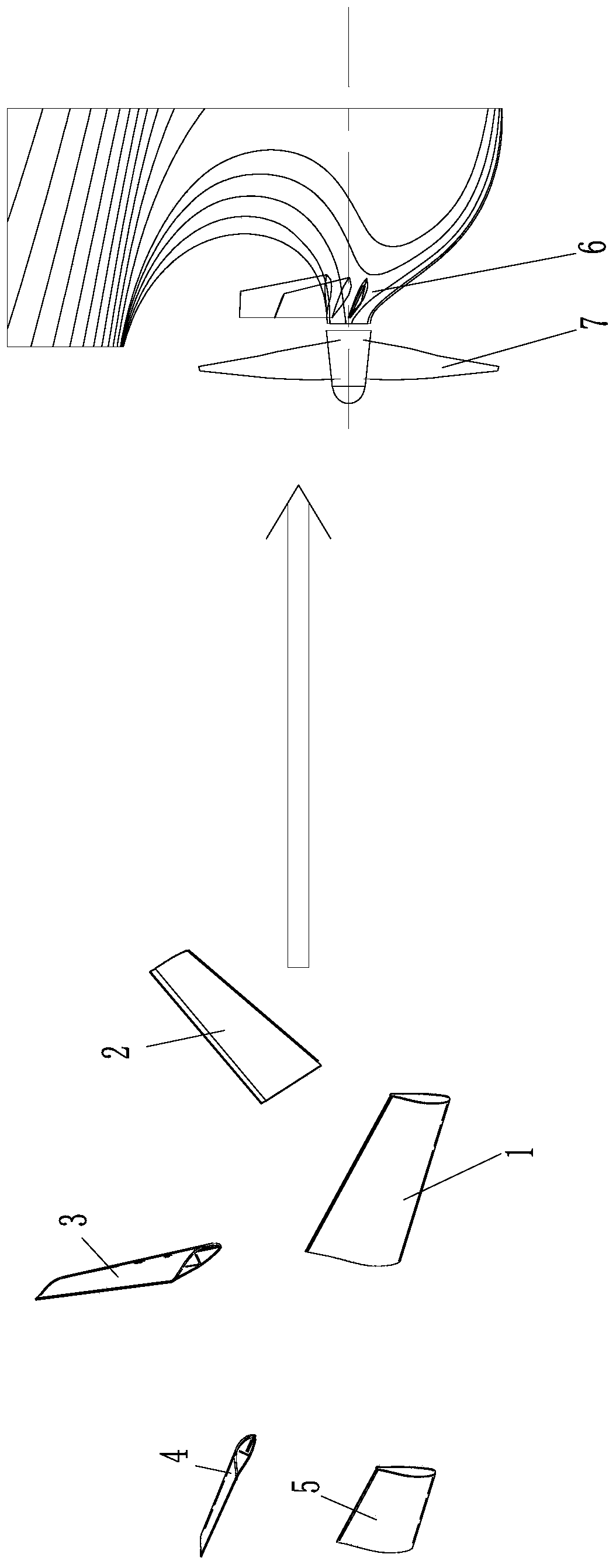

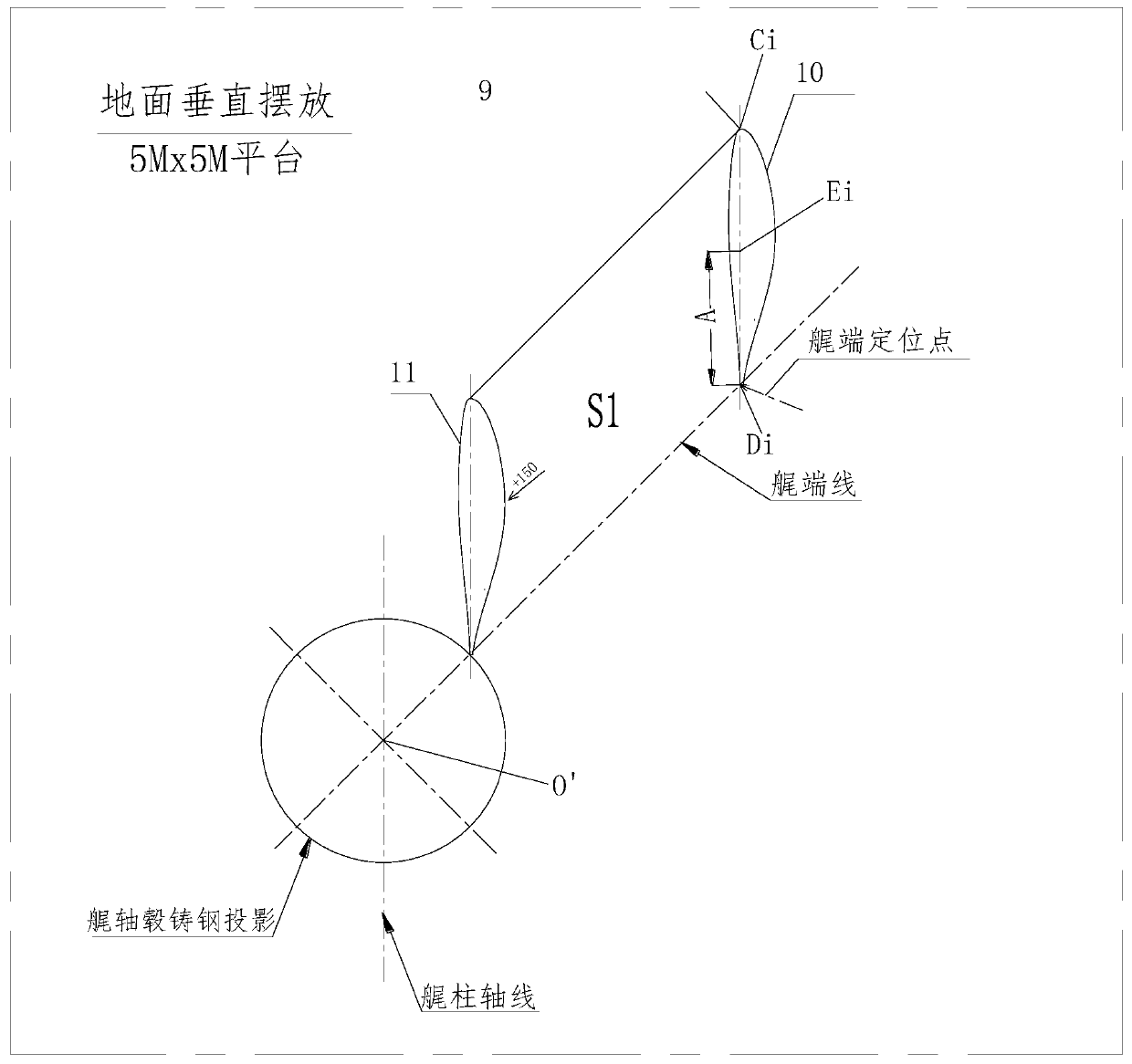

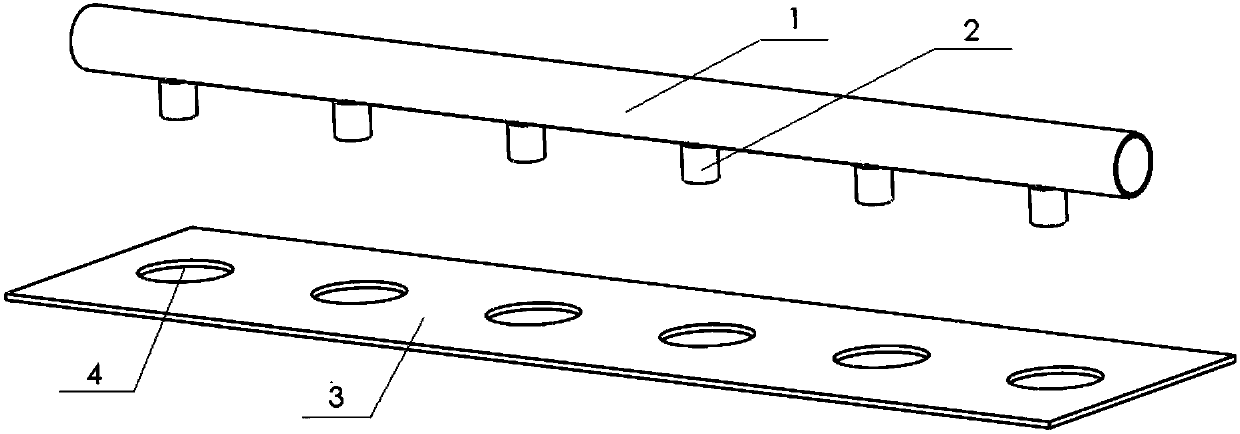

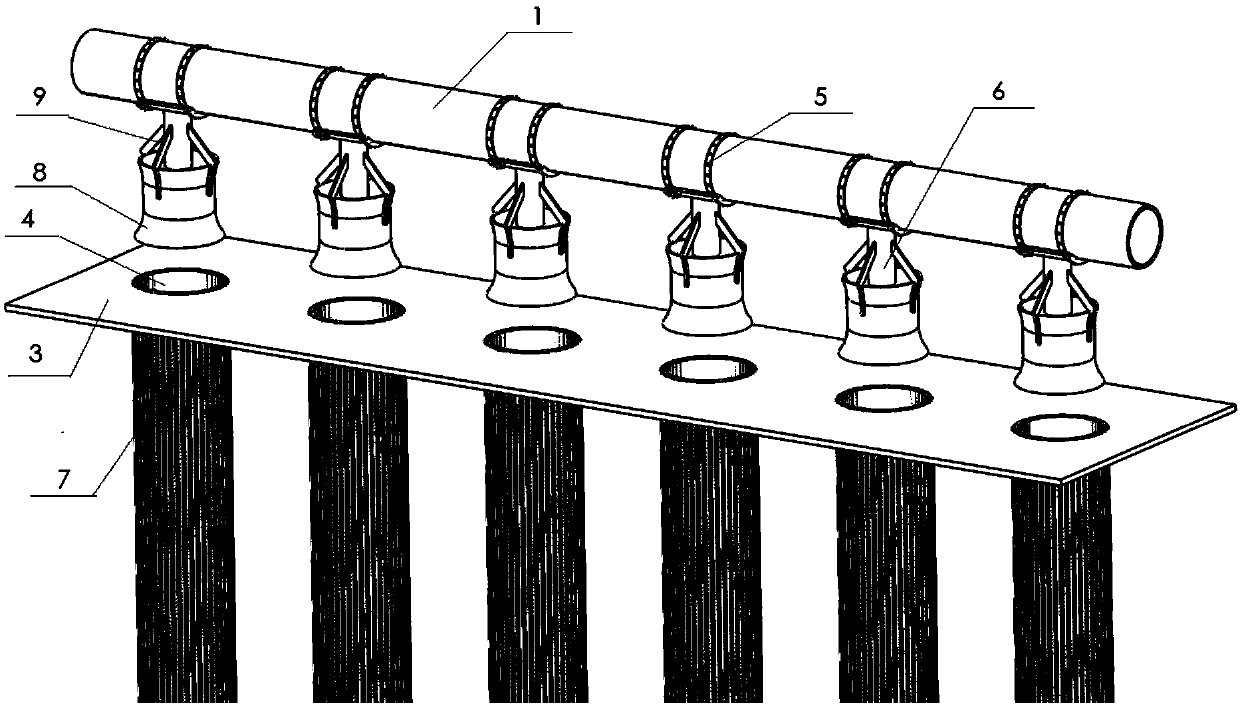

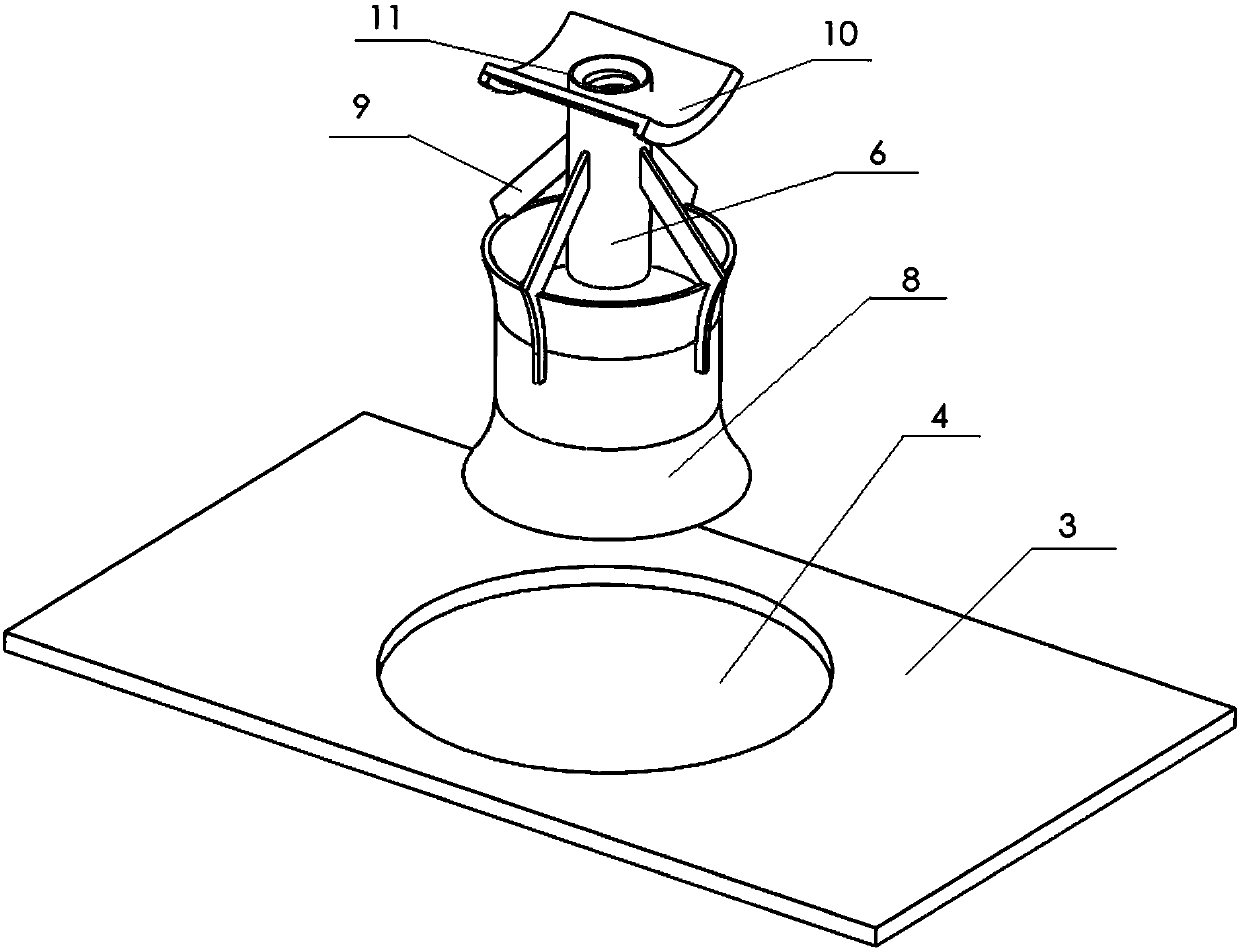

Mounting method of energy-saving stator

ActiveCN111498049ADifficulty solvingResolve accuracyWaterborne vesselsStructural engineeringMechanical engineering

The invention belongs to the technical field of ships, and relates to a mounting method of an energy-saving stator, which comprises the following steps of: (1) manufacturing fixed fins in a fragmentation manner, and reserving allowance on the folding end surface of each fixed fin; (2) inverting the tail shaft hub steel casting on a platform, and adjusting the tail shaft hub steel casting to a horizontal state; (3) adjusting the inclination angle and size of the manufactured fixed fin by using a total station and a plumb bob tool, and carrying out OTS pre-closure on the stator; (4) surveying and cutting the allowance of the closed end surface of the fixed fin in place by using a projection method; (5) resetting the trimmed fixed fins and the trimmed tail shaft hub steel casting again according to design requirements, fixing the inclination angles and the space positions of the fixed fins, wherein the adjacent fixed fins are in rigid connection through connecting pieces, and the fixed fins form a stator set; and (6) hoisting the stator group to the inverted tail shaft hub steel casting, and assembling the stator group and the tail shaft hub steel casting. The manufacturing and mounting precision is high, and the manufacturing and mounting period is effectively shortened.

Owner:中船澄西扬州船舶有限公司

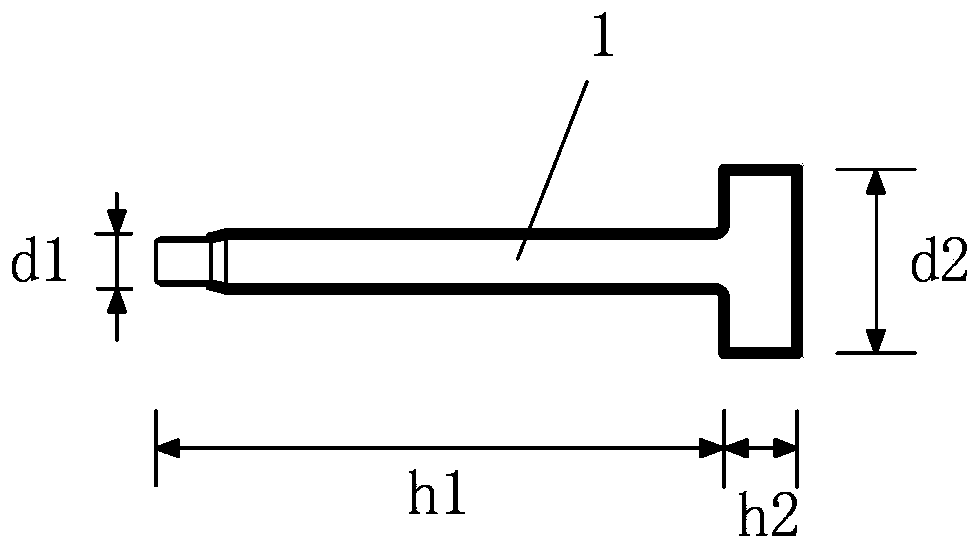

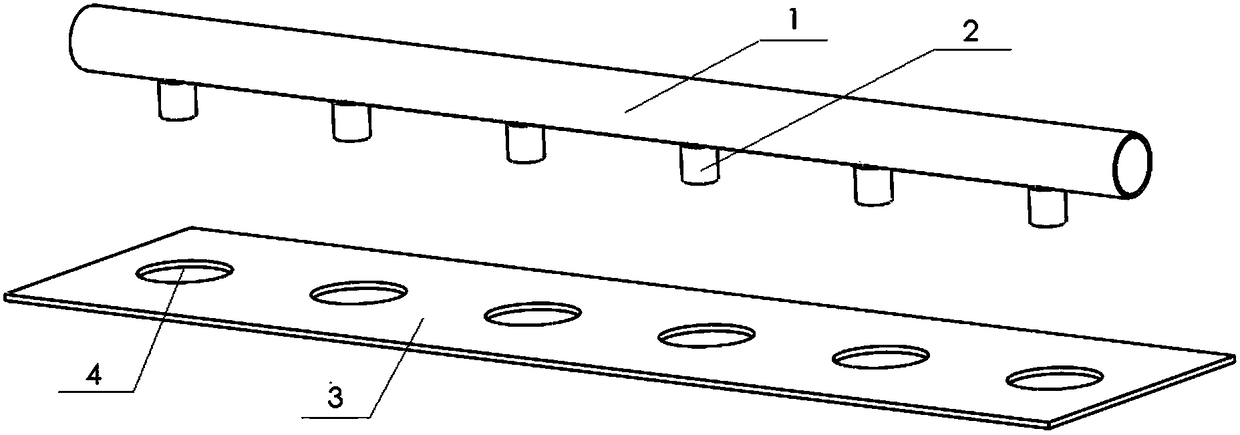

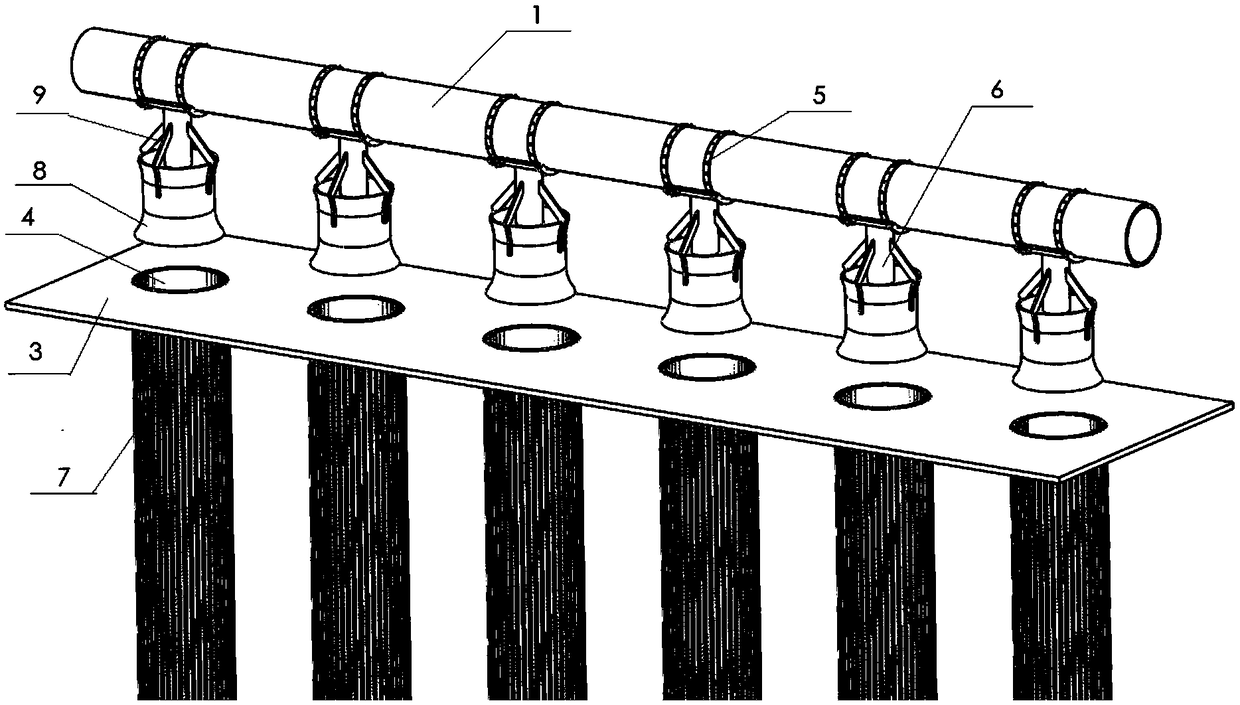

Venturi injection pipe for dust remover

ActiveCN107648952APrevent deviationGuaranteed accuracyDispersed particle filtrationTransportation and packagingNozzle

The invention discloses a Venturi injection pipe for a dust remover. The Venturi injection pipe comprises a diffusion pipe, Venturi nozzles and filter drums; air outlet holes are formed in the diffusion pipe; the upper end of each Venturi nozzle is fixedly arranged on one air outlet hole; a lower opening of each Venturi nozzle is arranged above an opening of one filter drum; each Venturi nozzle comprises a shell, a jet pipe and reinforcing ribs; each shell is a hollow column body; an upper opening and a lower opening of each shell are shaped like an outwards-expanded horn; the center of each shell is provided with one jet pipe; the periphery of each jet pipe is fixed together with the outer wall of one shell by using the plurality of reinforcing ribs; and spaces in each jet pipe and one shell are partitioned into a plurality of drainage air passages by the reinforcing ribs.

Owner:上海境业环保能源科技股份有限公司

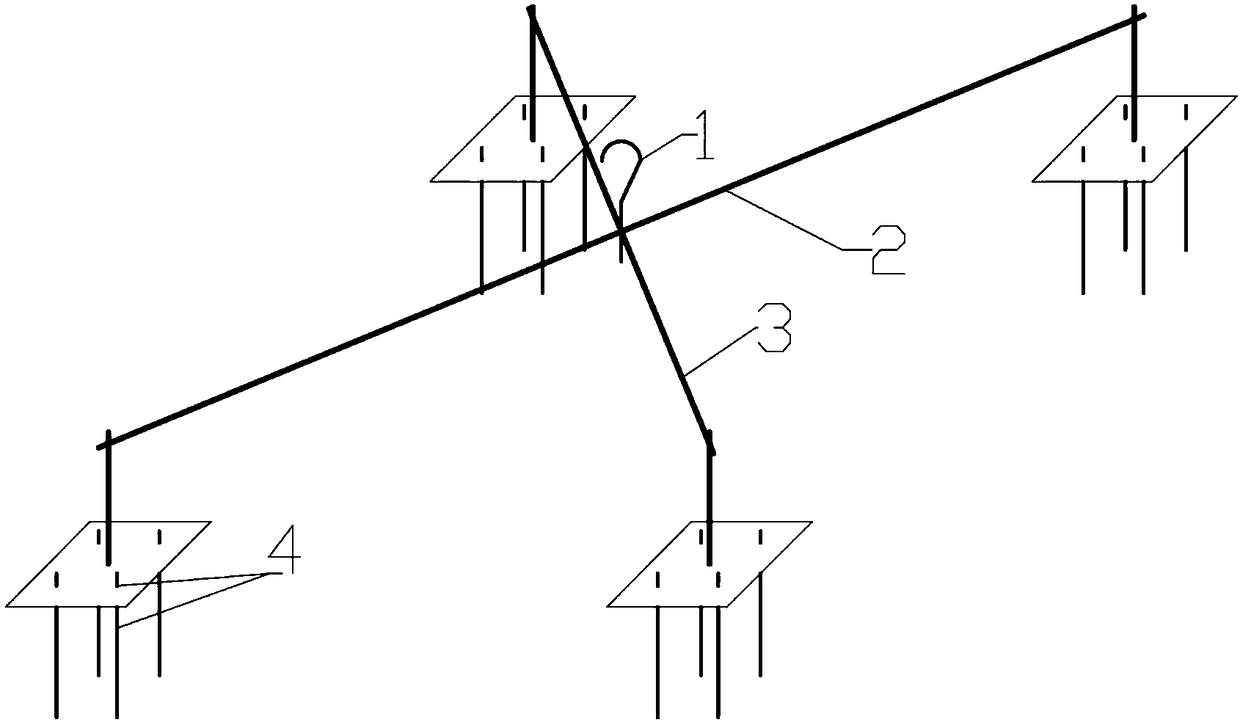

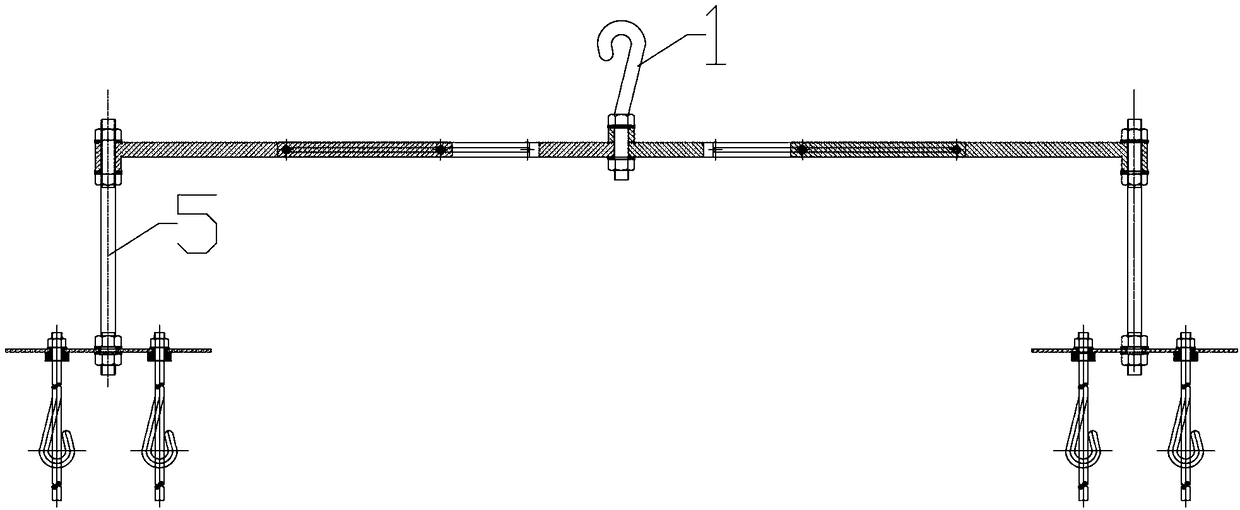

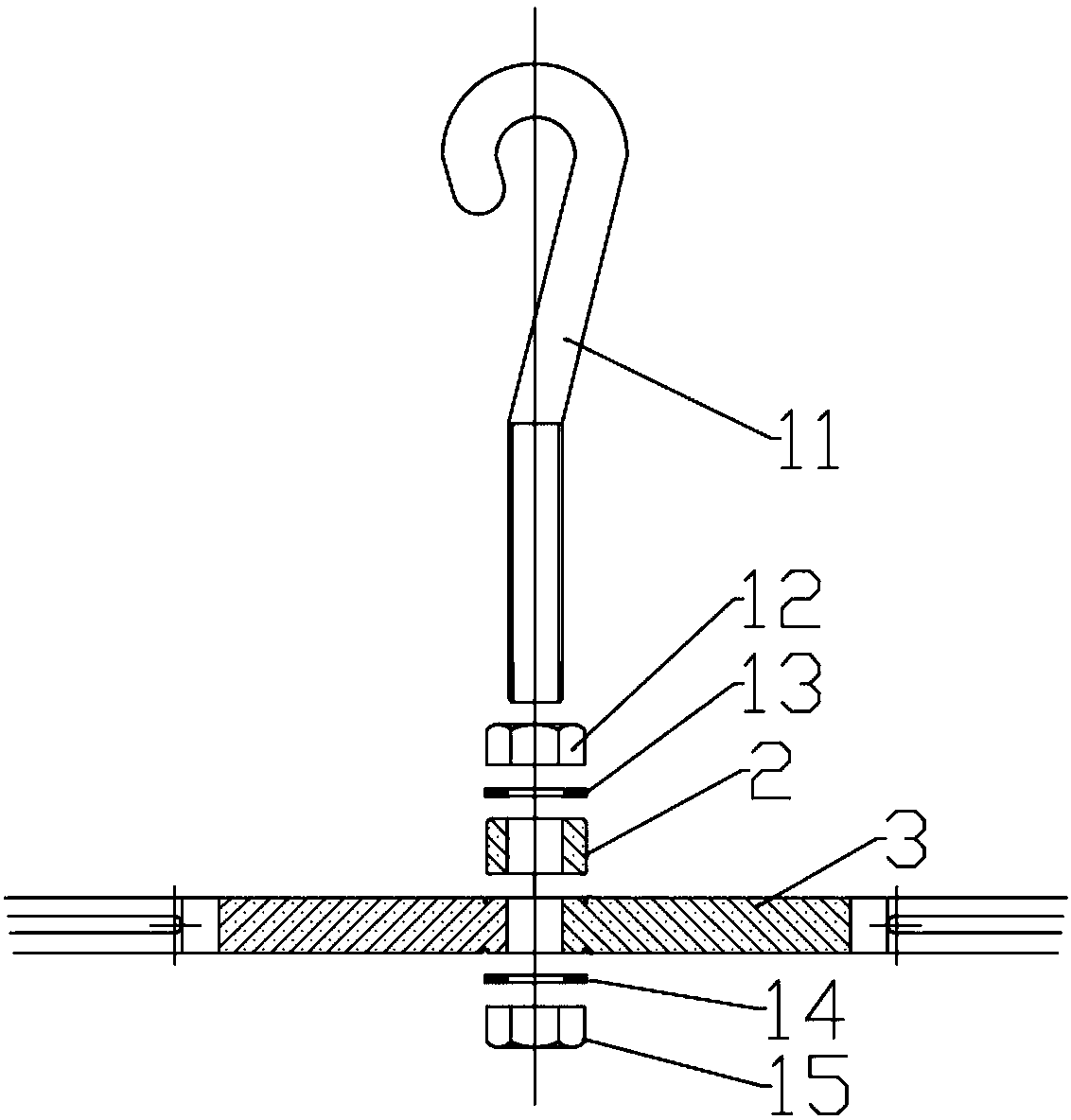

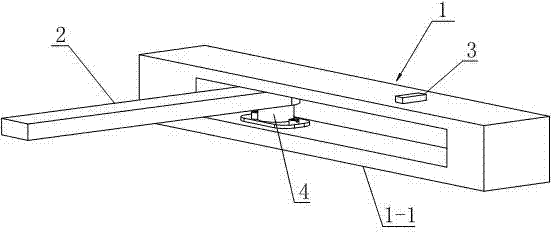

Anchor bolt positioning and correcting device and usage method

PendingCN108360825AImprove construction and demolition efficiencyEnsure equipment installation accuracy and use safetyFoundation engineeringBuilding material handlingSteel platesEngineering

The invention provides an anchor bolt positioning and correcting device comprising an X connecting frame which is of a cross structure formed by adjusting frames which are cross up and down. Adjustingarms are disposed at four ends of the upper adjusting frame and the lower adjusting frame, the adjusting arms are fixed on the adjusting frames through bolts and nuts, the tail end of each adjustingarm is connected with a positioning steel plate through a vertical connecting rod, the positioning steel plate is provided with a plurality of embedded anchor bolts, the embedded anchor bolts are provided with guide correction structures, the center of the X connecting frame fixes the upper adjusting frame and the lower adjusting frame through a lifting hook fastening structure, and the horizontaladjustment and positioning of the X connecting frame are achieved. The device is provided with an adjusting frame, and the anchor bolt size installation requirements of various mechanical devices canbe met to some extent; after the anchor bolt positioning and correcting device is introduced, the problem of perpendicularity of anchor bolt installation is solved while the anchor bolt installationposition precision is ensured, the construction and removal efficiency is improved, and the device installation accuracy and use safety are ensured.

Owner:SHENZHEN CONSTR GRP

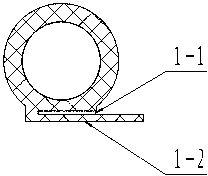

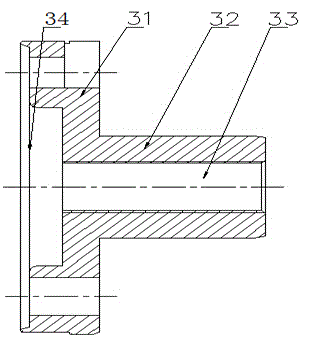

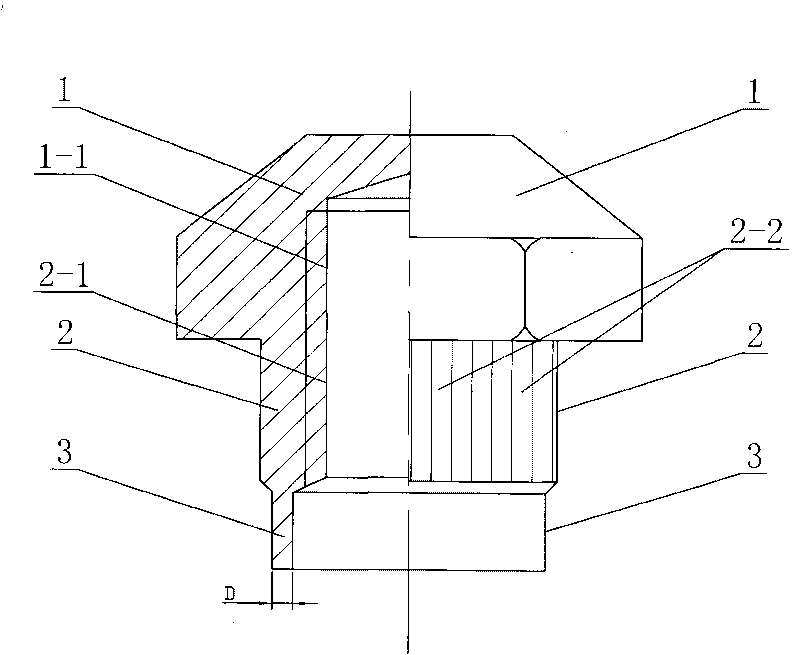

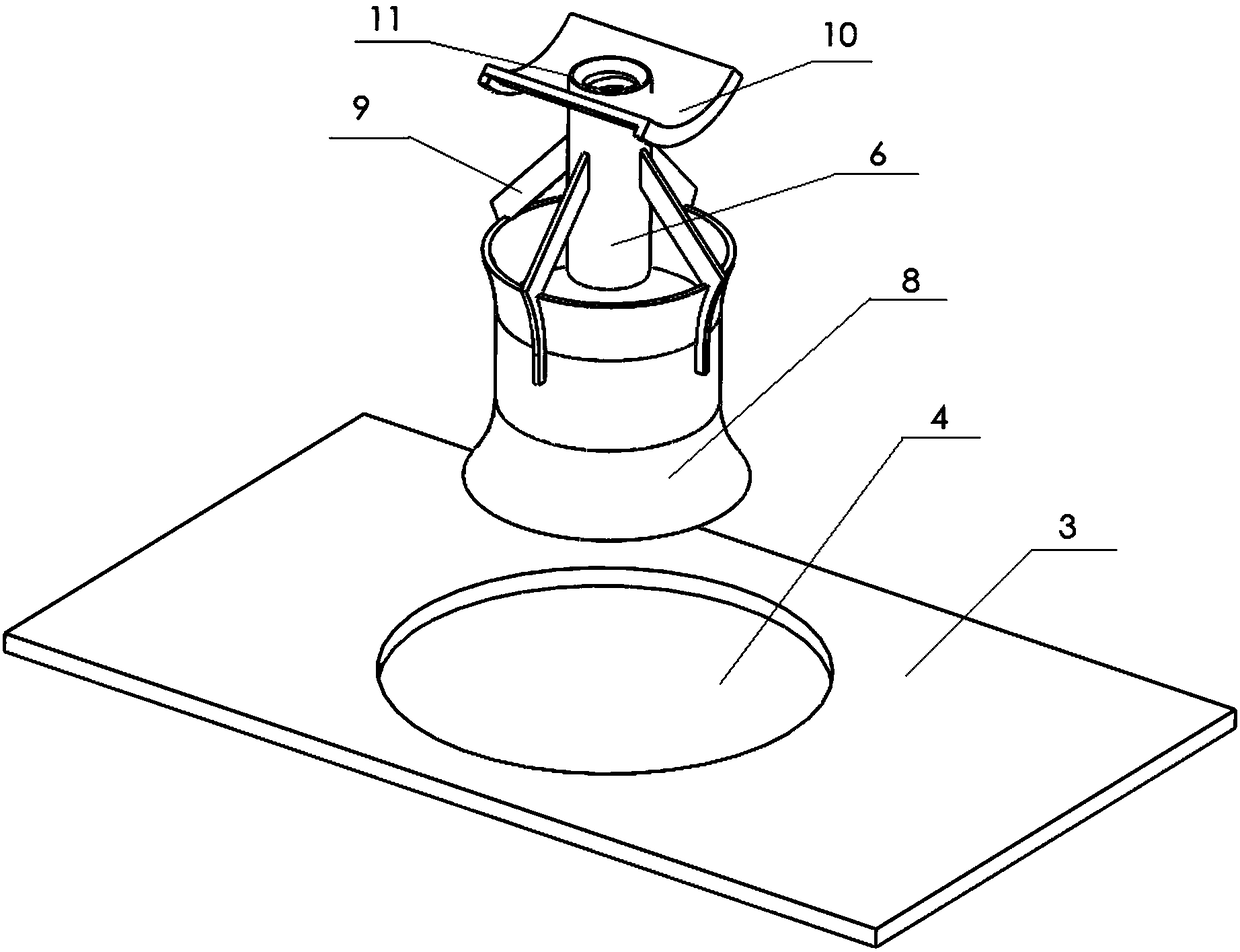

Embedded nut for connecting overlapping elements

InactiveCN101761537AGuaranteed installation position accuracyQuality improvementNutsScrew threadFactor of safety

The invention discloses an embedded nut for connecting overlapping elements, which relates to an embedded nut. The invention solves the problem that one side of the overlapping element is not suitable for screwing operation due to the factors of safety, space and the like, therefore, bolts and nuts can not be used for connecting the overlapping elements. The invention has the first scheme that the interior of a cap is provided with a thread blind hole in the axis direction; the interior of the nut main body is provided with a first thread through hole in the axis direction; the thread blind hole is communicated with the first thread through hole, and has the same hole diameter with the first thread through hole; and the cross section of the locking overlapping edge is in a circle shape. The invention has the second scheme that the interior of the cap is provided with a second thread through hole in the axis direction; the interior of the nut main body is provided with a third thread through hole in the axis direction; the second thread through hole is communicated with the third thread through hole, and has the same hole diameter with the third thread through hole; and the cross section of the locking overlapping edge is in a circle shape. The invention is fixed on the overlapping elements to be connected in advance, and the two overlapping elements can be quickly overlapped and connected through using bolts on one side of the overlapping element by operators.

Owner:HARBIN TOPFRP COMPOSITE

Motorcycle fairing structure assembly

InactiveCN104149887AImprove structural strengthGuaranteed installation position accuracyWeather guardsSteering columnEngineering

The invention discloses a motorcycle fairing structure assembly comprising a fairing back plate and a connecting plate on a motorcycle steering column. The motorcycle fairing structure assembly is characterized in that a mounting base and mounting columns are arranged on the fairing back plate, and the mounting columns are fixed on the motorcycle steering column correspondingly to the mounting base; mounting holes allowing the mounting columns to be inserted in and fixed are formed in the mounting seat, fixing holes are further arranged in the fairing back plate, and the fairing back plate is fixed on the steering column connecting plate through the fixing holes. A motorcycle applies the fairing back plate mounting assembly, structural strength of the mounting columns on the connecting plate on the motorcycle steering column is far higher than that of fairing back plate lugs in the prior art, the technical problems of breakage and deformation of the fairing back plate lugs in the prior art are solved, strength of the fairing back plate is improved, mounting position accuracy of the fairing guide plate and safety performance of motorcycle running are guaranteed, probability of occurrence of labor waste and material waste is reduced, and cost is saved.

Owner:CHONGQING LONCIN MOTOR

A soldering substrate for electronic products and its preparation method

ActiveCN103227161BGraphical lines with high precisionHigh precisionSemiconductor/solid-state device detailsSolid-state devicesThin membraneEngineering

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Measurement method for mounting and positioning of basic direct-buried foundation bolts of large-scale equipment

InactiveCN102912813AGuaranteed installation position accuracyGuaranteed accuracyFoundation testingConstruction engineeringAnchor bolt

The invention discloses a measurement method for the mounting and positioning of basic direct-buried foundation bolts of large-scale equipment, comprising the steps of finding and marking cross central points of single basic direct-buried foundation bolts and measuring the lengths of two diagonal lines of a rectangle formed by lines of centers of four adjacent basic direct-buried foundation bolts. A used measurement device consists of two structural steel door-shaped frames, a steel wire, a wire grip, a portable electronic scale, a steel tape and a conical check head, wherein two ends of the steel wire are respectively connected onto the two structural steel door-shaped frames; one end of the steel wire is connected with the steel tape and the other end of the steel wire is connected with the portable electronic scale and the wire grip; and the conical check head is arranged on the measured foundation bolt. The method is used for measuring the mounting and positioning precisions of the basic direct-buried foundation bolts of the large-scale equipment and has the advantages of being simple in operation and improving the construction efficiency and the mounting precision.

Owner:SINOHYDRO BUREAU 14 CO LTD

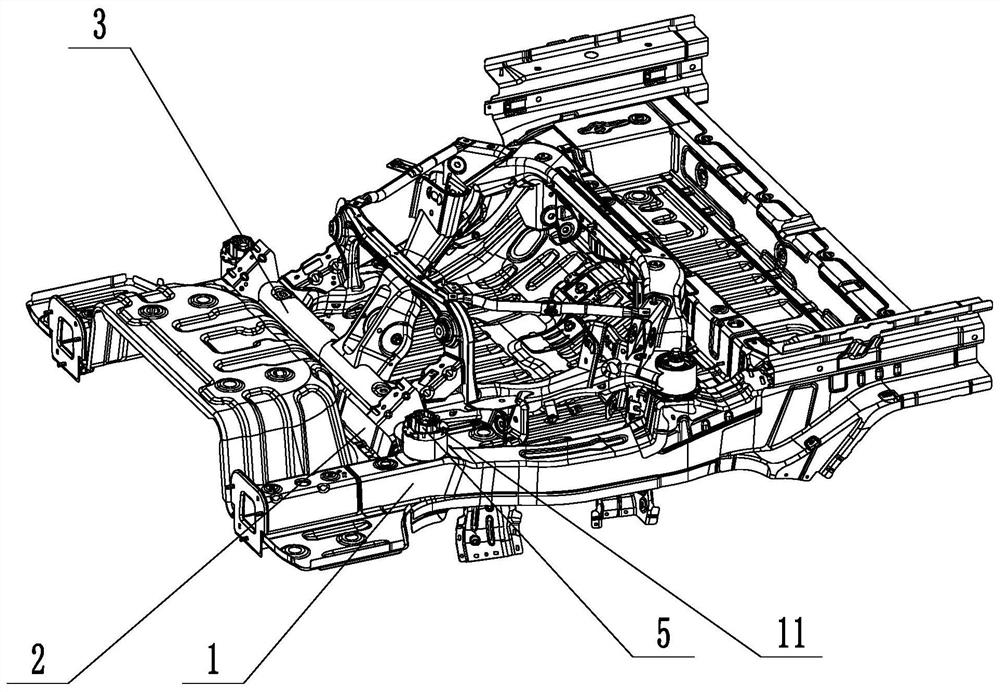

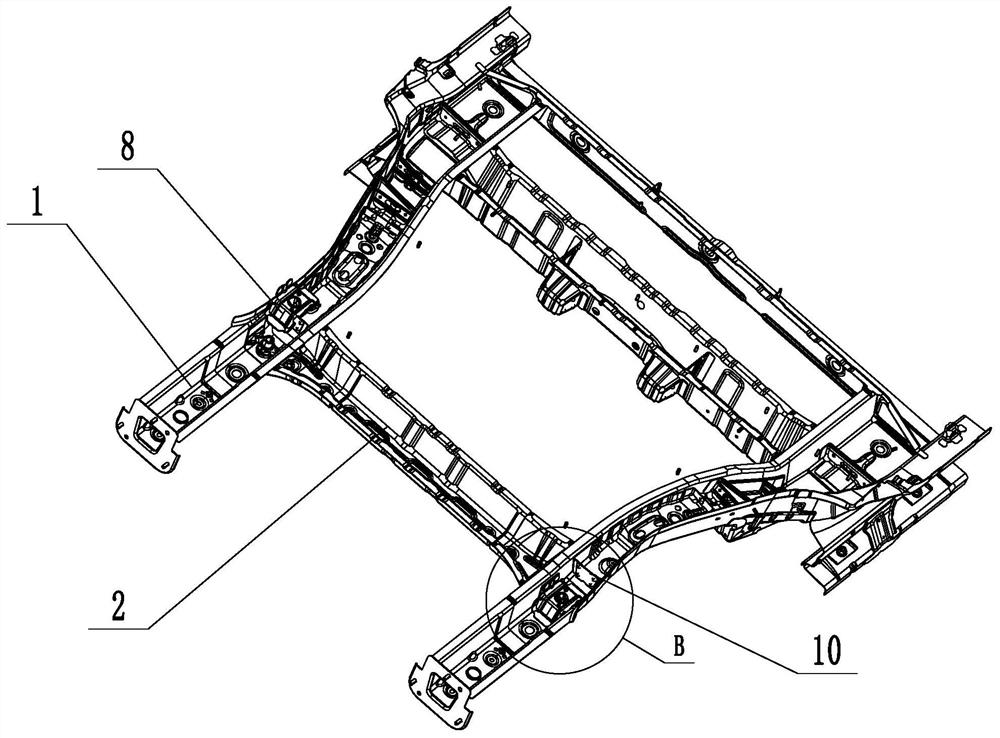

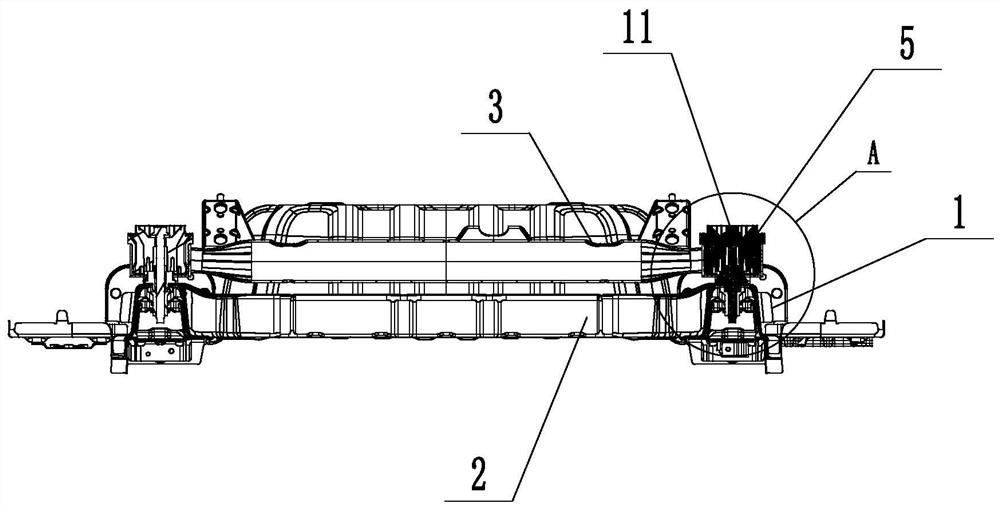

Positioning and mounting structure for rear auxiliary frame of electric vehicle

ActiveCN111661155AImprove installation positioning accuracyGuaranteed installation position accuracyUnderstructuresSuperstructure connectionsVehicle frameEngineering

The invention discloses a positioning and mounting structure for a rear auxiliary frame of an electric vehicle. The structure comprises rear longitudinal beams, a rear cross beam and a rear auxiliaryframe; two ends of the rear cross beam are respectively fixed with the rear longitudinal beams on two sides; a positioning connecting pipe is arranged at the joint of the rear cross beam and the rearlongitudinal beams; a positioning counter bore is formed in the positioning connecting pipe; a connecting threaded hole is formed in the bottom face of the positioning counter bore; a positioning bushing is arranged on the rear auxiliary frame; the positioning bushing is fixed to the rear auxiliary frame; the positioning bushing is provided with a positioning boss; a through hole is formed in thepositioning bushing; the through hole penetrates through the positioning bushing and the positioning boss; the positioning boss is matched with the positioning counter bore; and a mounting bolt penetrates through the through hole to be connected with the connecting threaded hole. With the positioning and mounting structure for the rear auxiliary frame of the electric vehicle of the invention adopted, the mounting and positioning precision between a vehicle body and the rear auxiliary frame is improved, a mounting process is simplified, and overall rigidity and strength are improved.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

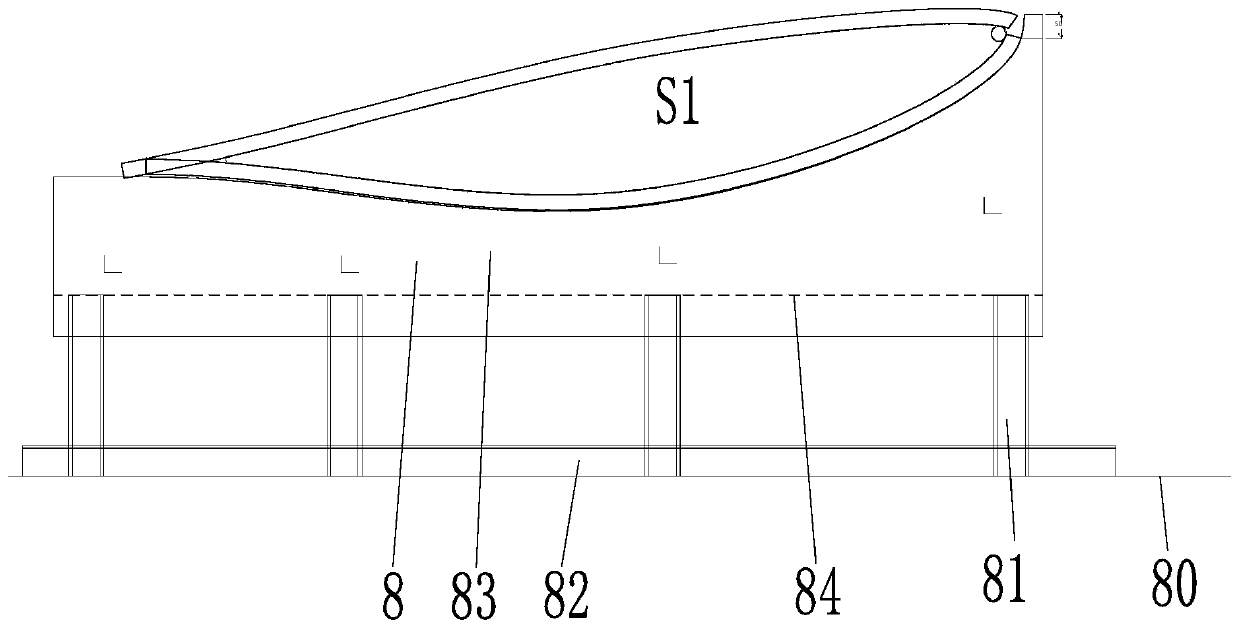

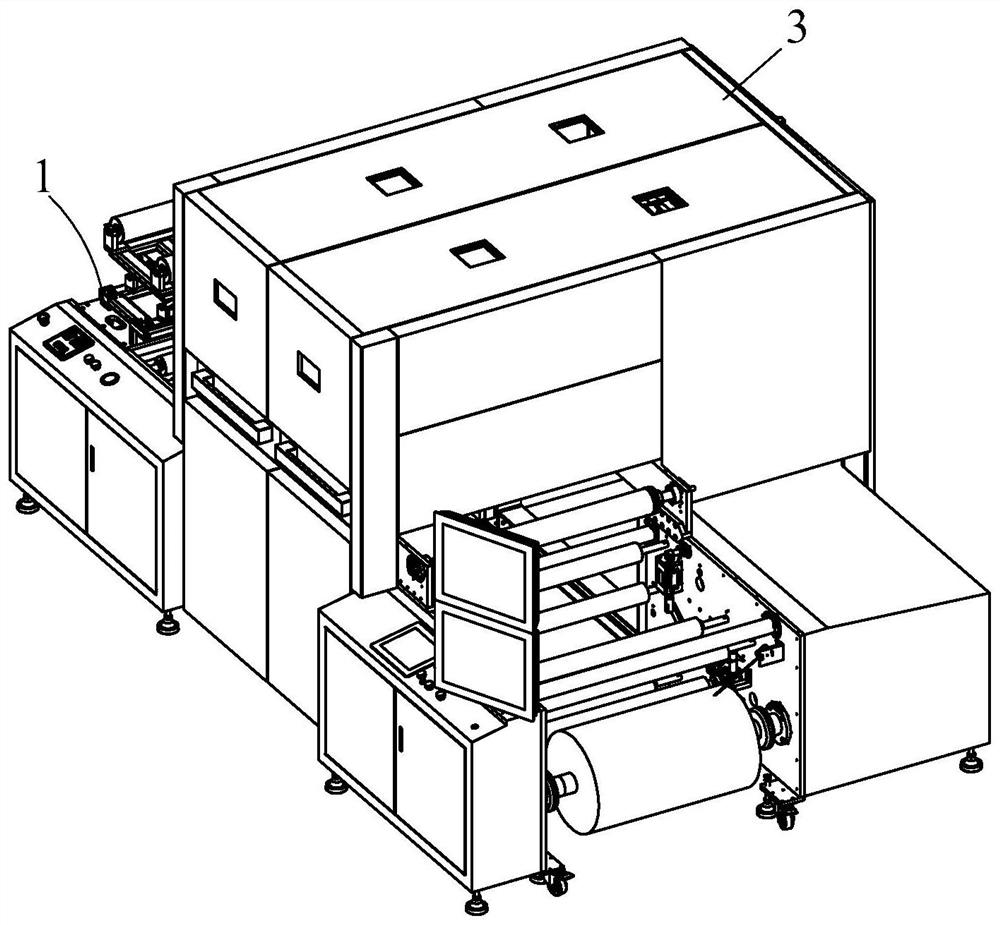

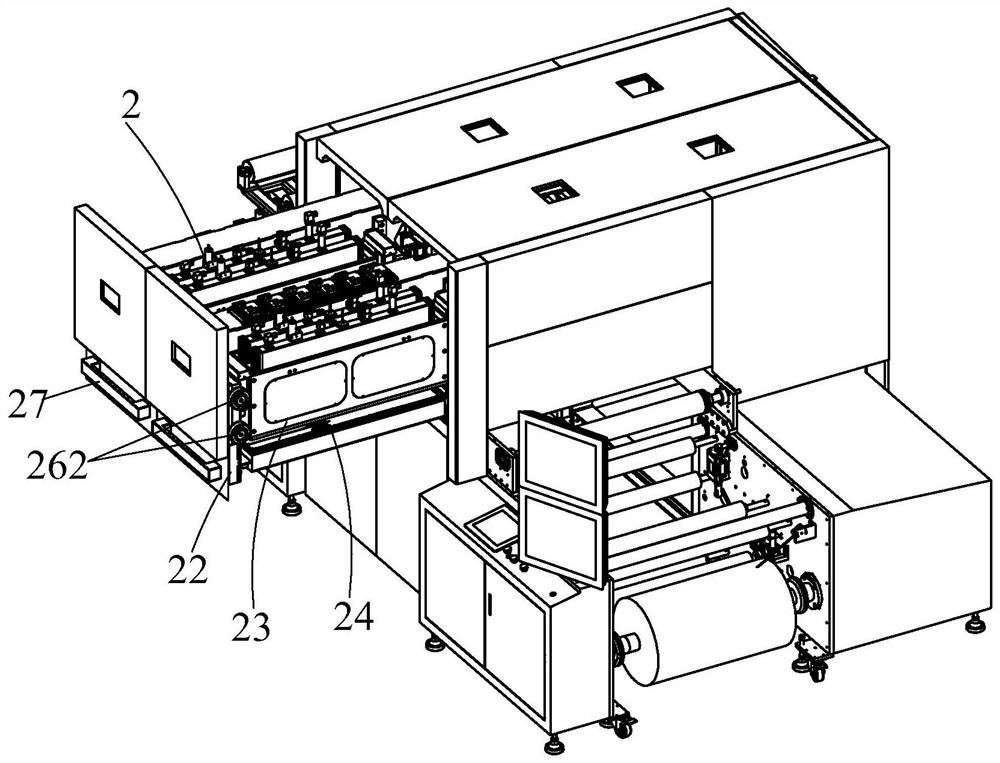

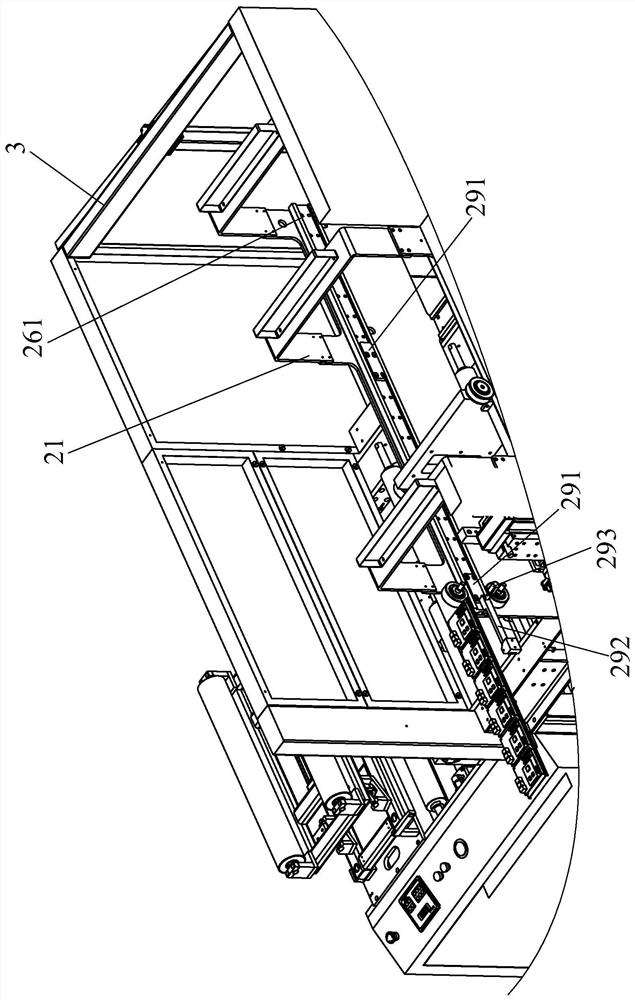

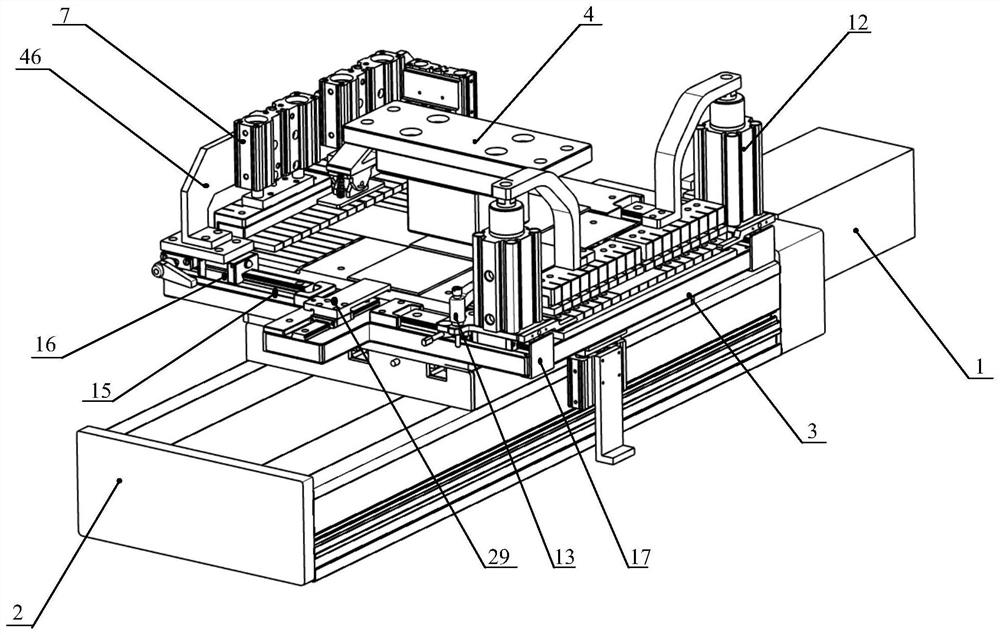

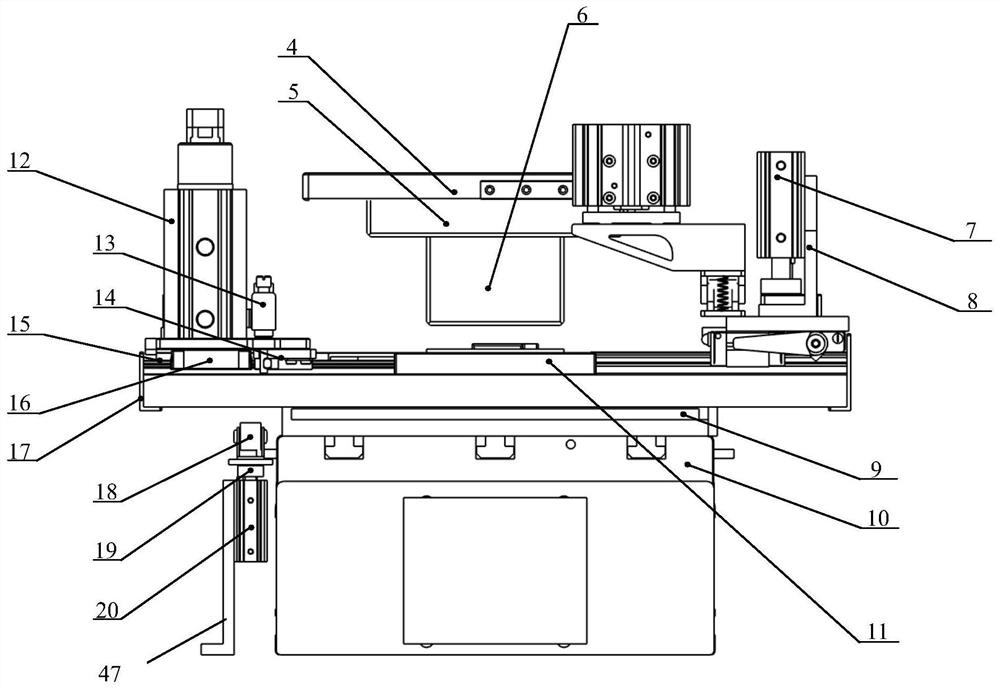

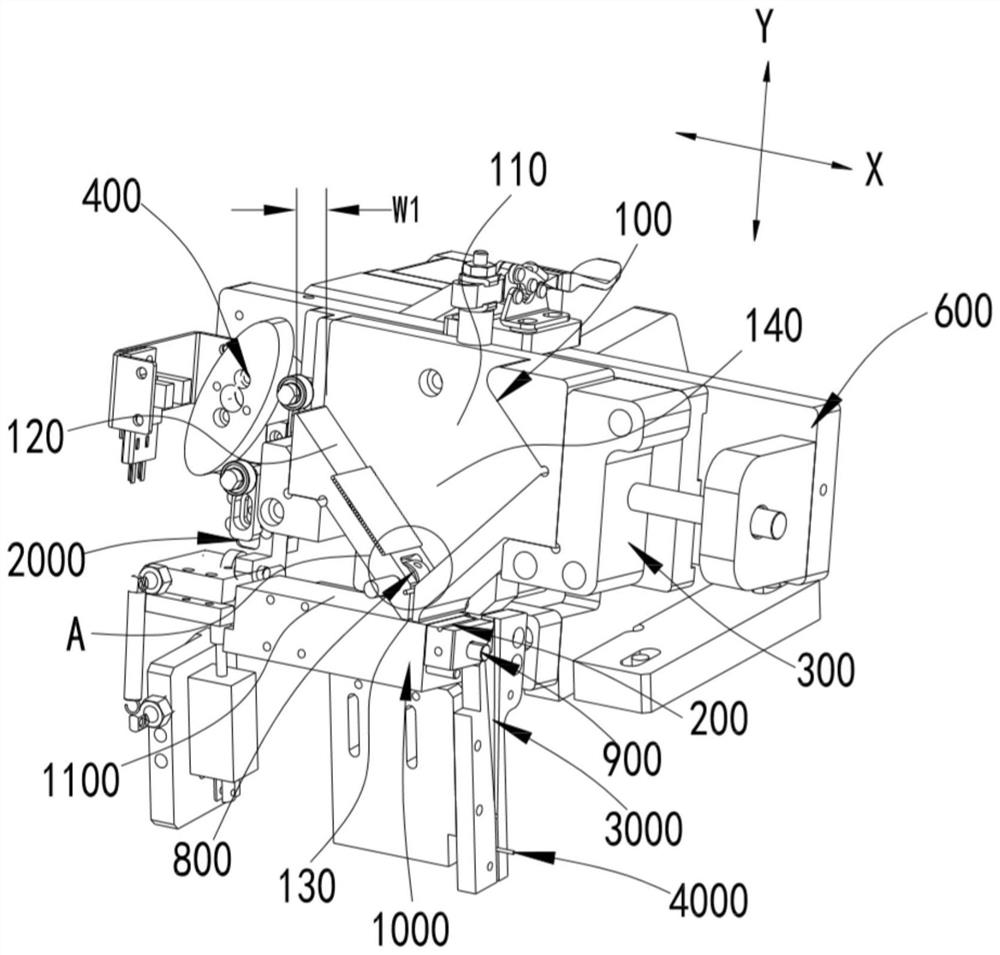

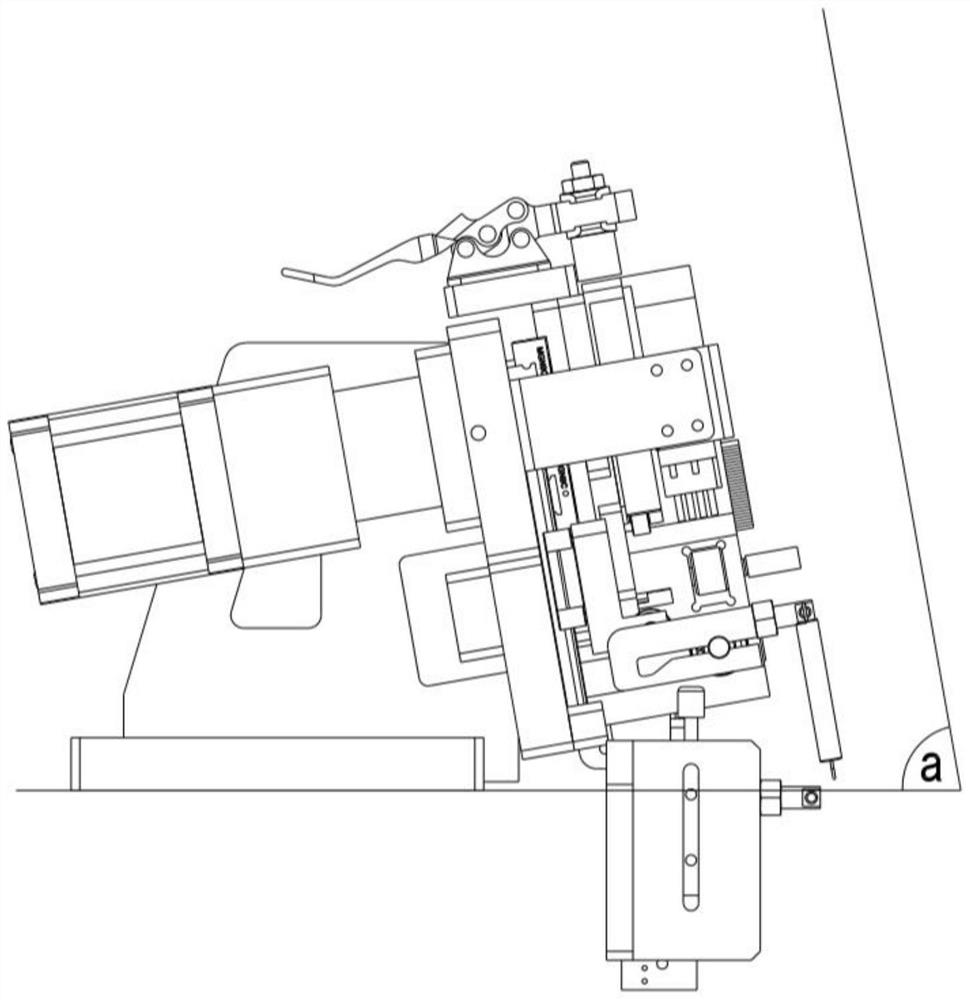

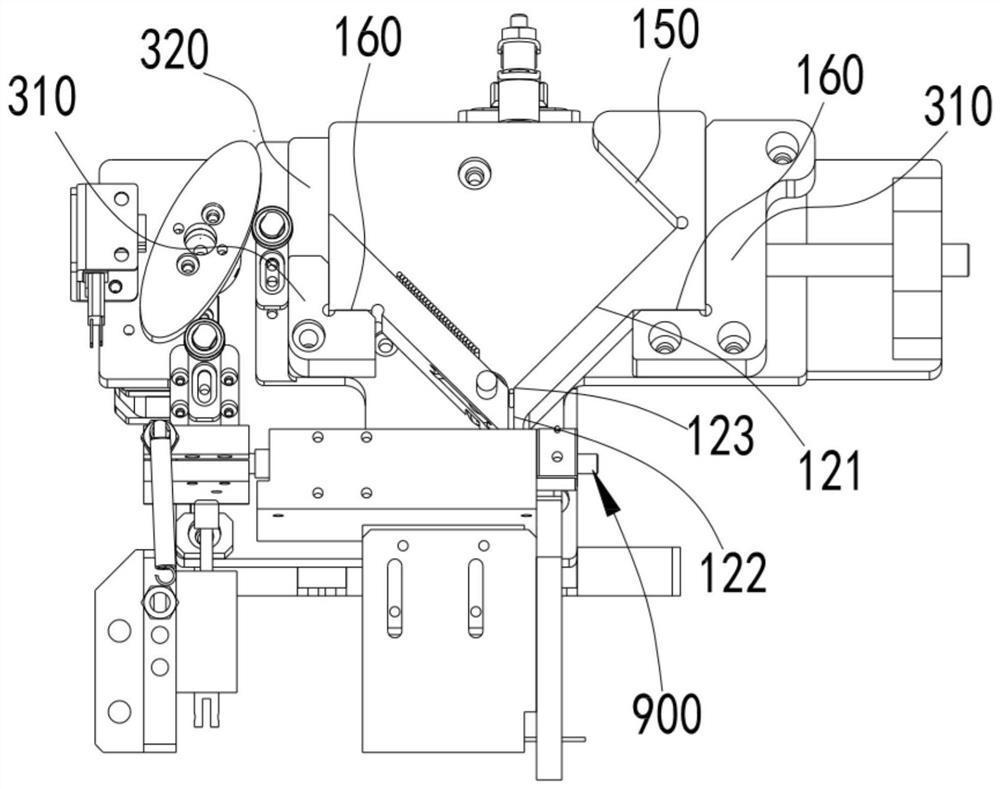

Push-pull type printing system and continuous ink-jet printing machine

ActiveCN112976808AWork lessReasonable designTypewritersPower drive mechanismsTextile printerEngineering

The invention relates to a push-pull type printing system and a continuous ink-jet printing machine. The push-pull type printing system comprises a gantry frame, an outer frame and a spray head frame provided with a spray head group, the gantry frame is fixedly installed on a machine frame of the continuous ink-jet printing machine and is located above a printing guide belt; the spray head frame is installed in the outer frame in a multi-direction adjustable mode through a spray head set multi-direction adjusting mechanism, the outer frame is movably placed between a pull-out position and a push-in position relative to the gantry frame through a push-pull moving mechanism, part of the outer frame is pulled out of the gantry frame at the pull-out position, and at a push-in position, the part of the outer frame is pushed into the gantry frame. The continuous ink-jet printing machine is provided with the push-pull type printing system. The push-pull type printing system can be integrally pushed in and pulled out, the whole printing system is pulled out when overhaul and daily maintenance are needed, and overhaul work of maintainers is greatly facilitated.

Owner:HANGZHOU HONGHUA DIGITAL TECH

Enhanced corrugated filtration pipe dust removing device

PendingCN108067058ASolution to short lifeLow costGas treatmentDispersed particle filtrationFiltrationBiochemical engineering

The invention discloses an enhanced corrugated filtration pipe dust removing device, which comprises a pulse valve arranged on a gas collection box, a blowing main pipe communicated to the gas outletof the gas collection box, and a blowing device arranged on the blowing main pipe, wherein a flower plate is arranged below the blowing device, and is provided with an opening corresponding to the blowing device, and a corrugated filtration unit is arranged at the opening position. According to the present invention, the blowing device uses the Venturi spraying nozzle, and the corrugated filtration unit uses the enhanced corrugated filtration pipe, such that the service life of the product is substantially prolonged, the standardized production can be conveniently achieved, the production efficiency is improved, and the production and maintenance cost can be reduced.

Owner:上海境业环保能源科技股份有限公司

A flexible resistance welding device for thermoplastic composite materials

ActiveCN109940897BGuarantee welding qualityEnsure welding stabilityDomestic articlesElectric machineryElectric resistance welding

The invention discloses a thermal plastic composite material flexible resistance welding device. The device comprises a servo driving motor, a precision roller guiding rail linear movement system anda thermal plastic composite material resistance welding platform, wherein the precision roller guiding rail linear movement system is of a rectangular structure, the top face is provided with a rack in the length direction, and power output is provided by the servo driving motor; the thermal plastic composite material resistance welding platform can be installed on the precision roller guiding rail linear movement system by moving along the rail on the precision roller guiding rail linear movement system. The device has the advantages that welding lower pressure is provided through the servo pressure system, a to-be-welded part is positioned and resistance heating are conducted by a key type flexible electrode module, welding current is guided by connecting the electrode module, and therefore the purpose of thermal plastic composite material static and continuous dynamic flexible resistance welding is achieved.

Owner:CIVIL AVIATION UNIV OF CHINA

A construction method and device for a gate slot

ActiveCN103074872BGuaranteed installation position accuracyGuaranteed accuracyBarrages/weirsWater-power plantsMechanical engineeringOpen air

The invention designs a gate slot construction device, which is used for realizing rapid gate slot construction of a gate by adopting a mechanical process. The device is provided with a gate slot positioning and clamping mechanism and a steel template, wherein left and right side members of each section of gate slot are connected with a climbing mechanism; after a gate slot is arranged, the lower end of the gate slot is kept fixed; a gate slot pouring space is closed by using the steel template, and concrete is poured; and the gate slot climbing device climbs by one section after one layer of concrete is poured every time. A truss structure in a novel gate slot construction device for the gate has the characteristics of high overall rigidity, high reliability and generality in a certain size range, so that the conventional open air dangerous operation way is turned into a way which is centered by highly mechanical assembly operation and assisted by manual operation, the construction safety and quality of a gate slot for a planar gate or an arc-shaped gate are guaranteed easily, and maximization of an engineering economic value is realized through a rapid construction way.

Owner:CHENGDU ALANGTECH

Rod body separation device and method and rod body assembly equipment and method

PendingCN112077559AReduce in quantityLow costMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a rod body separation device and method, rod body assembly equipment and method. The rod body separation device is provided with rod body inclined space with an open outer end,so that the corresponding contact with the reaction end surface of the outer end of the rod body is avoided, and the pollution of the reaction end surface is effectively avoided; meanwhile, the rod body is slantwise arranged to ensure that the rod body does not drop out of the rod body inclined space; in addition, separation is performed through the gravity of the rod body, so that the reaction end surface damage caused by collision between the rod bodies due to vibration of a feeder can be effectively avoided, the quality of the reaction end surface of the rod body after output is effectively guaranteed, and the assembling efficiency of the finished product is improved. In addition, a receiving groove is obliquely arranged, so that the bar body can automatically slide downwards into a subsequent structure through gravity, and the structure simplification is facilitated.

Owner:星童医疗技术(苏州)有限公司

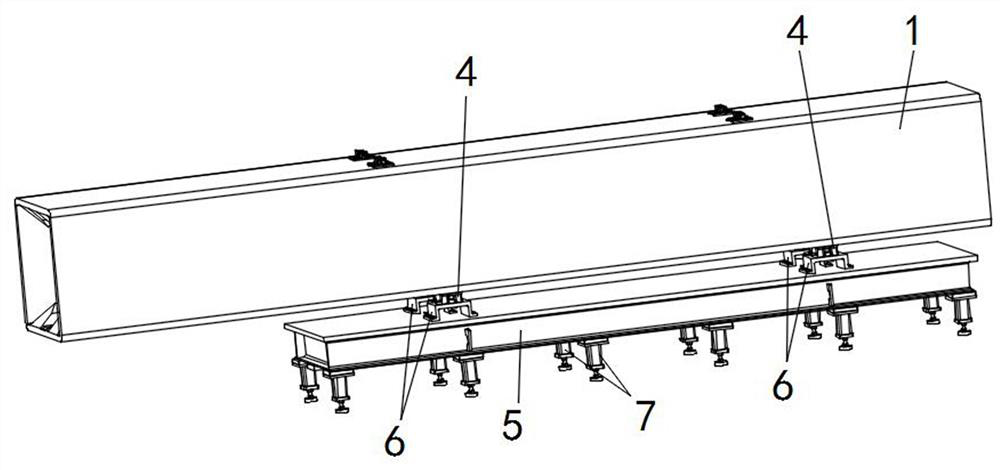

A storage and transportation launch box precision adjustment device and adjustment method thereof

ActiveCN114543583BAccurate adjustment of straightnessPrecise level adjustmentMissile propulsionControl engineeringComputer science

The invention discloses a storage and transportation launch box precision adjustment device and an adjustment method thereof. First, the installation and positioning accuracy of a simulation debugging platform is adjusted to meet the standard, and then a matching connection and an installation position are arranged between the storage and transportation box body and the simulation debugging platform. The flexible and adjustable locking adjustment component and locking positioning component are used to detect the installation positioning error through the sample column that is slidably installed inside the storage box body, and then flexibly adjust the gap between the locking adjustment component and the locking positioning component in real time according to the positioning error. Therefore, the accuracy of the installation position of the storage box body itself is up to the standard, thereby ensuring that the levelness, straightness and axial positioning position accuracy of the final solid part or device installed inside the storage box body are up to the standard.

Owner:AEROSPACE WANXIN SCI & TECH CHENGDU

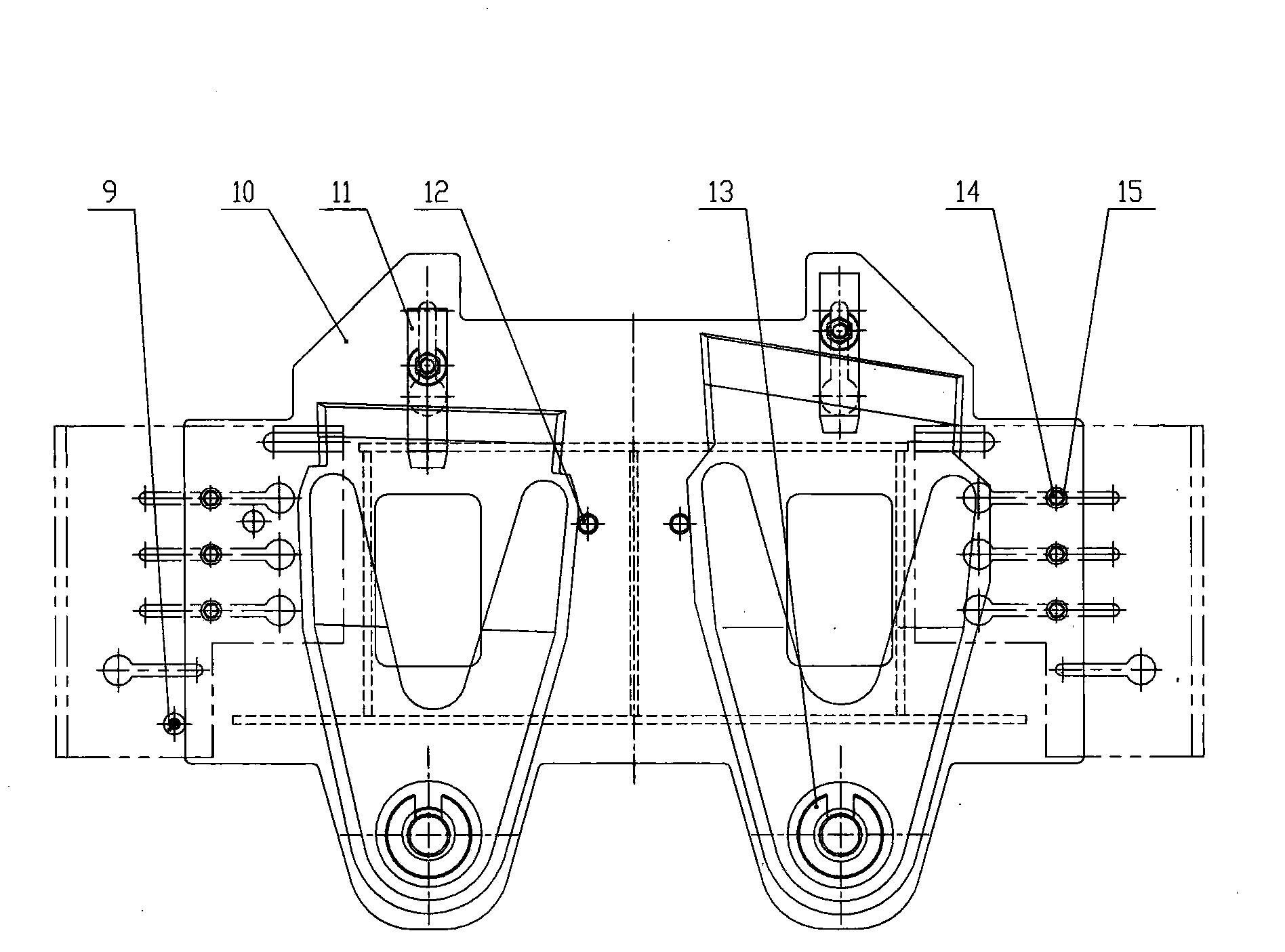

Method for machining universal robot welding fixture of middle-large size excavator movable arm and supporting base

ActiveCN103341708BEasy to useGuaranteed reliabilityWelding/cutting auxillary devicesAuxillary welding devicesInterference fitExcavator

The invention provides a method for machining a universal robot welding fixture of a middle-large excavator movable arm and a supporting base. Firstly, an appropriate plate is selected for serving as a base; secondly, a first positioning pin is assembled on a welding robot working table on one side; the base is locked on the welding robot working table; two second positioning pins are assembled in the middle of the base, and the second positioning pins are in interference fit with the base; two holes are drilled in the rear side of the base, threaded rods are inserted into the holes, and positioning sleeves are assembled on the threaded rods; a workpiece is placed on the base, positioned and locked; an U-shaped hole is machined in the front side of the base, and pressing plates are installed in the U-shaped hole, so that the pressing plates are made to press and firmly lock the workpiece. According to the provided method, the defects in the prior art are overcome, welding precision is high, machining time is short, in addition, performance is reliable, precision of installation positions of the movable arm and a bucker rod is guaranteed, and then using performance and reliability of the movable arm are guaranteed.

Owner:龙工(上海)挖掘机制造有限公司

A kind of installation equipment of automobile door sealing strip

An installation device for an auto door seal strip of an automobile is used for solving installation problems of an integral 3M glue-bonding seal strip. The installation device for the auto door seal strip of the automobile comprises a fixed sliding rail, a horizontal-moving sliding rail, a sliding trolley, and a profiling frame. The fixed sliding rail is composed of two longitudinal rails. The horizontal-moving sliding rail is horizontally arranged and is assembled with the fixed sliding rail. The sliding trolley is assembled with the horizontal-moving sliding rail. The profiling frame is hung below the sliding trolley. The outline of the profiling frame is matched with a door fame. A pressing mechanism is arranged on the outer side of the profiling frame in the circumferential direction. The pressing mechanism is composed of a set of pressing units which are closely arranged. According to the installation device for the auto door seal strip of the automobile, a seal strip is prevented from being drawn in an installation process, distortion of the seal strip when the seal strip is bonded is eliminated, precision of the installation and positioning of the seal strip is guaranteed, and assembly quality of the seal strip is improved.

Owner:长城汽车股份有限公司平湖分公司

Installation and positioning ruler for wall-mounted panels and installation and positioning methods for wall-mounted panels

ActiveCN104515501BGuaranteed installation position accuracyGuaranteed working lifeLighting and heating apparatusSpace heating and ventilation detailsElectric machineryControl switch

The invention provides a wall-hung plate installation positioning rule and a wall-hung plate installation positioning method, and aims to solve the problems that in the prior art the positioning precision in wall-hung plate installation cannot be guaranteed, and the installation positioning efficiency is low. The wall-hung plate installation positioning rule comprises a fixed rod and a rotation positioning rod; the fixed rod has a fixed surface and is provided with an electric rotation mechanism and a level meter; the electric rotation mechanism comprises a control switch, a motor and a control element, wherein the motor and control element are arranged in the electric rotation mechanism; the horizontal direction of the level meter is perpendicular to the length direction of the fixed rod, one end of the rotation positioning rod is fixedly connected to the output shaft of the motor, and the length direction of the rotation positioning rod is parallel to the fixed surface of the fixed rod. By using the provided wall-hung plate installation positioning rule to position a wall-hung plate, the inclined angle of the wall-hung plate can be controlled precisely, and thus the positioning precision is guaranteed, so the condensed water in the water-receiving disc can be smoothly and completely discharged on the basis that the normal operation and service life of air conditioner are not affected, and the installation positioning efficiency is greatly improved at the same time.

Owner:HAIER GRP CORP +1

Connecting device and connecting method for T-shaped steel keel of inclined curtain wall

The invention discloses a connecting device and a connecting method for a T-shaped steel keel of an inclined curtain wall. The connecting device comprises a connecting device main body for connecting T-shaped steel (1) and a connecting plate (5), and a glass curtain wall (4) connected with the connecting plate; the connecting device main body comprises fixing columns (3), connecting blocks (6), connecting columns (7) and a sliding locking assembly; first through holes are formed in the T-shaped steel and the connecting plate, and the fixing columns penetrate through the T-shaped steel and the connecting plate through the first through holes; clamping grooves (8) are formed in the two ends of the fixing columns, the two connecting blocks are buckled in the clamping grooves in a matched mode, the two ends of each connecting block extend outwards to form connecting convex parts and are provided with second through holes, the connecting columns penetrate through the two connecting convex parts through the second through holes, and the two connecting blocks form a locking ring structure matched with the clamping grooves through the two connecting columns; and the connecting columns are movably connected with the fixing columns through the sliding locking assembly. Rapid connection of the curtain wall can be achieved, the locking reliability of connecting joints is high, the construction quality is ensured, the construction efficiency is improved, and disassembly and assembly are convenient.

Owner:中建八局装饰工程有限公司 +1

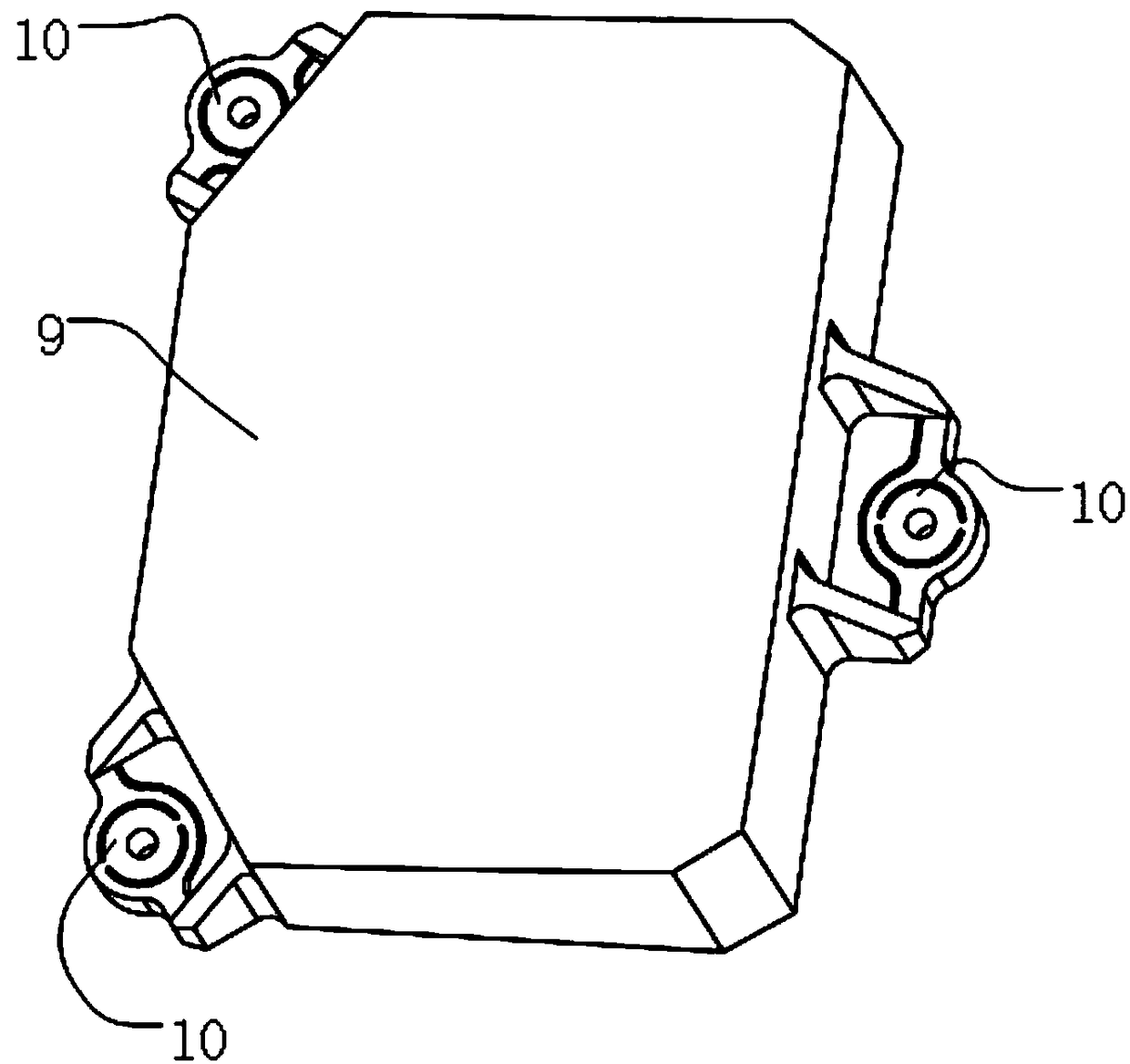

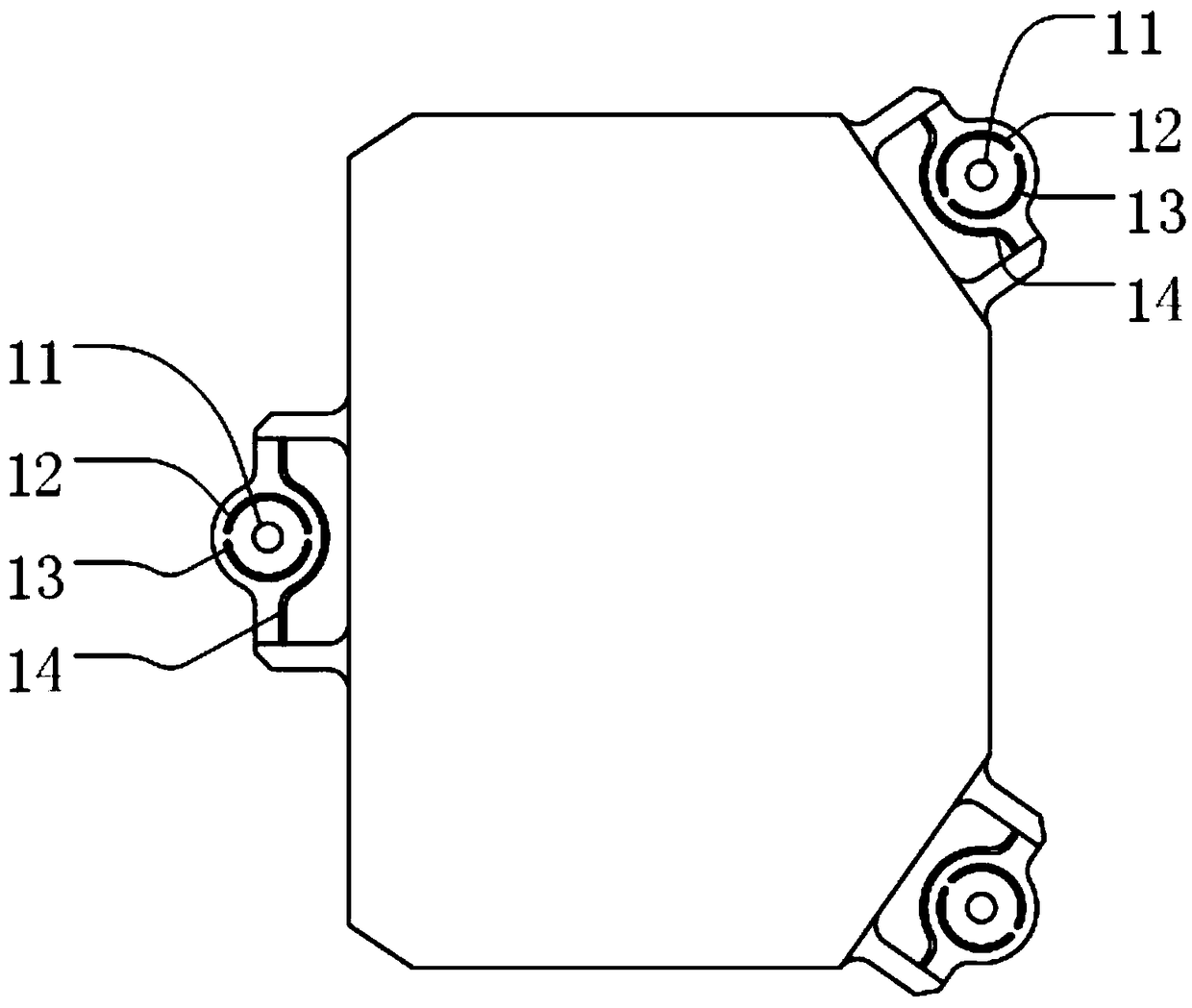

An integrated flexible support structure for a rectangular off-axis metal mirror

ActiveCN106610517BGuaranteed Surface AccuracyGuaranteed installation position accuracyMountingsPetroleum engineering

An integrated flexible support structure of a rectangular off-axis metal mirror belongs to the technical field of optical remote sensing. The support structure includes a mirror body and three flexible supports; wherein, the three flexible supports are arranged on the side surface of the mirror body with a uniform circumference; each flexible support includes a flexible board and two connection platforms, and the flexible board is fixed to the mirror body connection, the flexible board is provided with installation positioning screw holes, a first flexible slot, a second flexible slot and a third flexible slot, the first flexible slot and the second flexible slot are arc-shaped and arranged symmetrically with respect to the installation positioning screw holes, The middle part of the third flexible slot is arc-shaped, coaxial with the first flexible slot and the second flexible slot and arranged vertically. The connection platforms are respectively fixed on both sides of the flexible board. Fixed connection with the mirror body. The support structure can greatly reduce the change of gravity, the change of temperature and the internal stress of the mirror generated in the assembly process, and ensure the surface shape accuracy and the installation and positioning accuracy.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

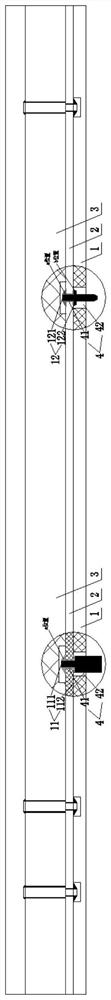

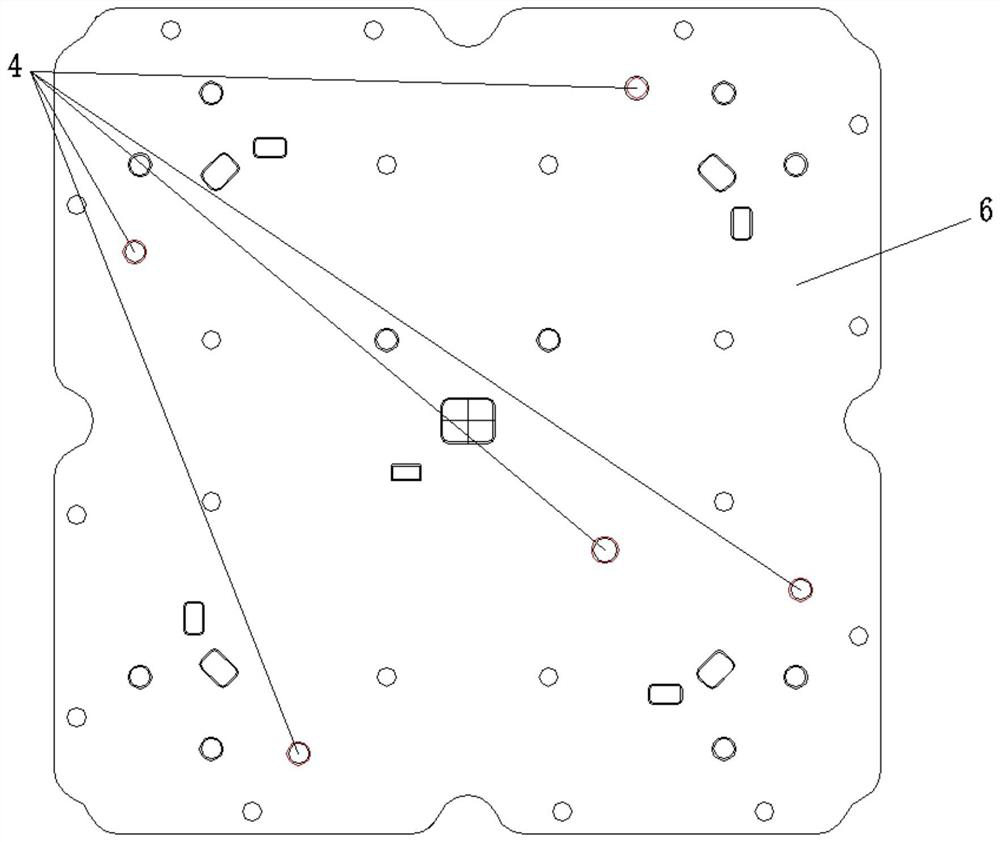

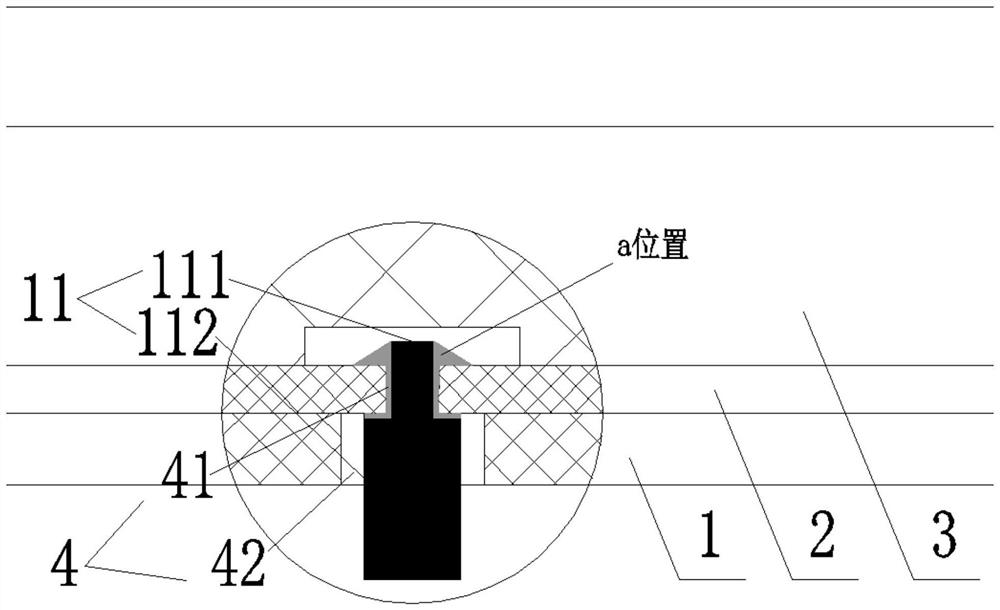

A combined array element precise alignment assembly device and method

ActiveCN112496488BAvoid forceAccuratePrinted circuit assemblingMetal working apparatusElectrical conductorStructural engineering

The invention discloses a precise alignment assembly device and method for a combined array element. Through careful analysis of the structural size of the combined array element, a special welding alignment tooling fixture for the combined array element is designed, and a positioning column is used to align the inner The position of the conductor is precisely positioned, and the butt slot of the inner conductor is designed according to the size of the alignment hole of the filter, and welding is performed after the butt joint to ensure that the position accuracy of the inner conductor meets the requirements; and the welding process is improved, and the inner conductor is added to the inner conductor cylinder before welding. The outer circular surface is tinned. When soldering, first solder at the position a of the inner conductor of the printed board, and then solder at the position b around the lower end of the inner conductor to ensure a good soldering between the inner conductor and the pad of the printed board. The shape of the spot ensures the strength of the solder joint; after the inner conductor is welded, it can be aligned with the filter accurately, preventing the inner conductor from being stressed after the assembly of the combined array element, and obtaining good assembly quality.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

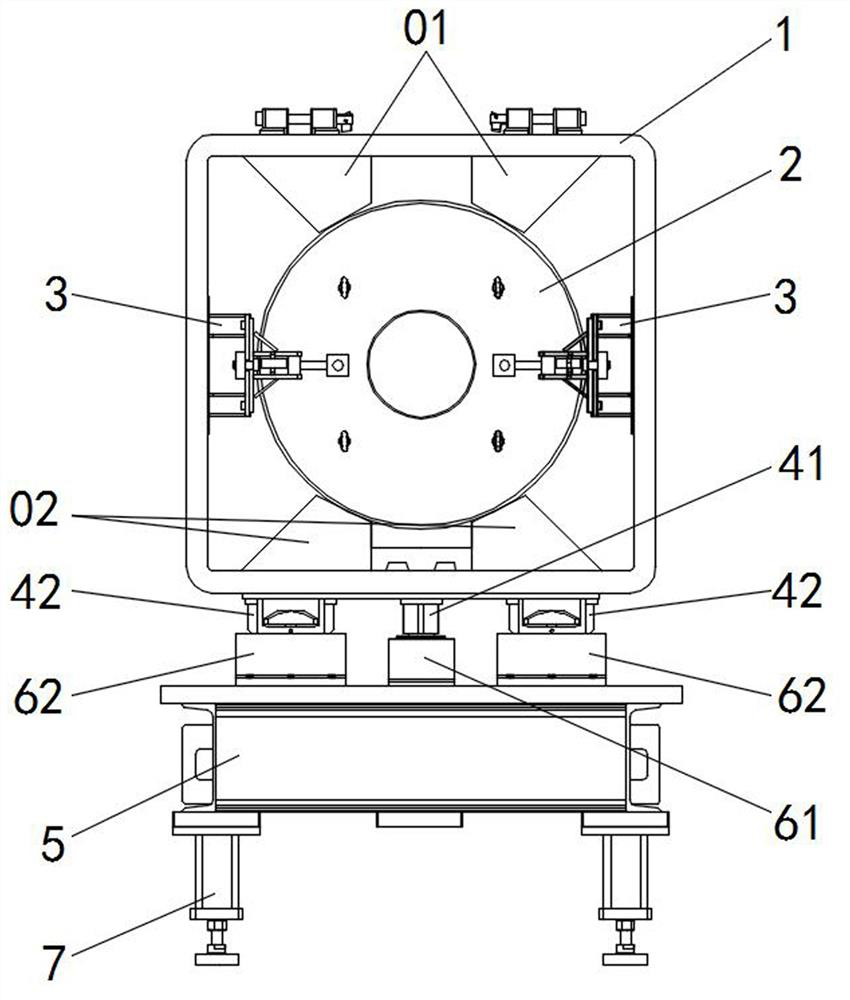

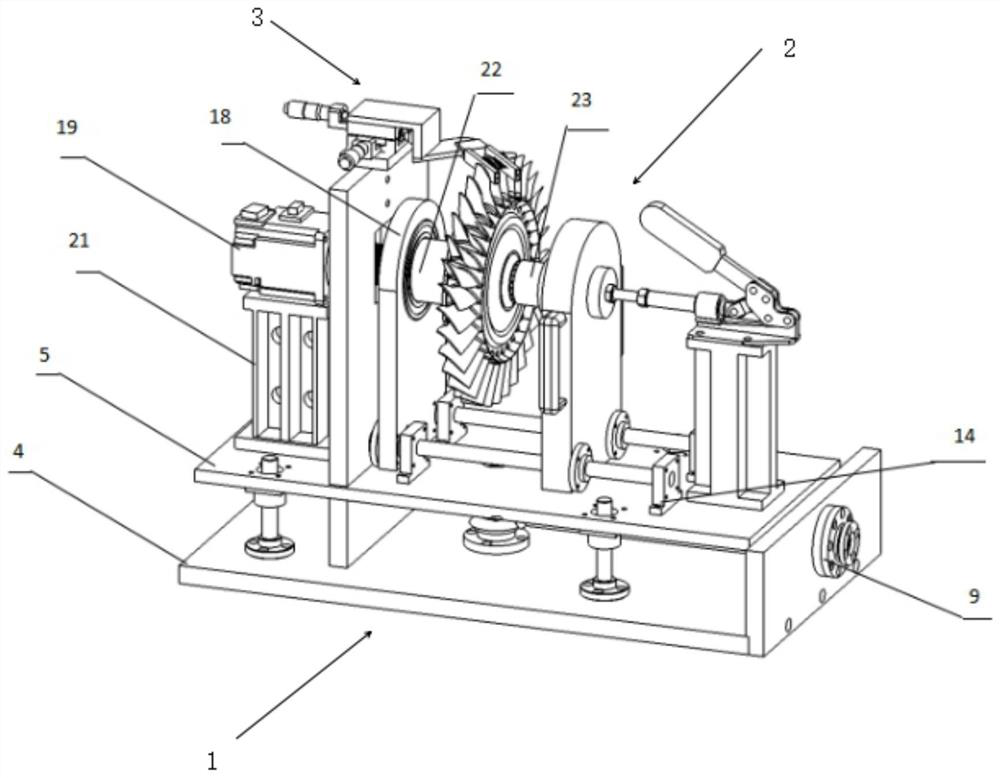

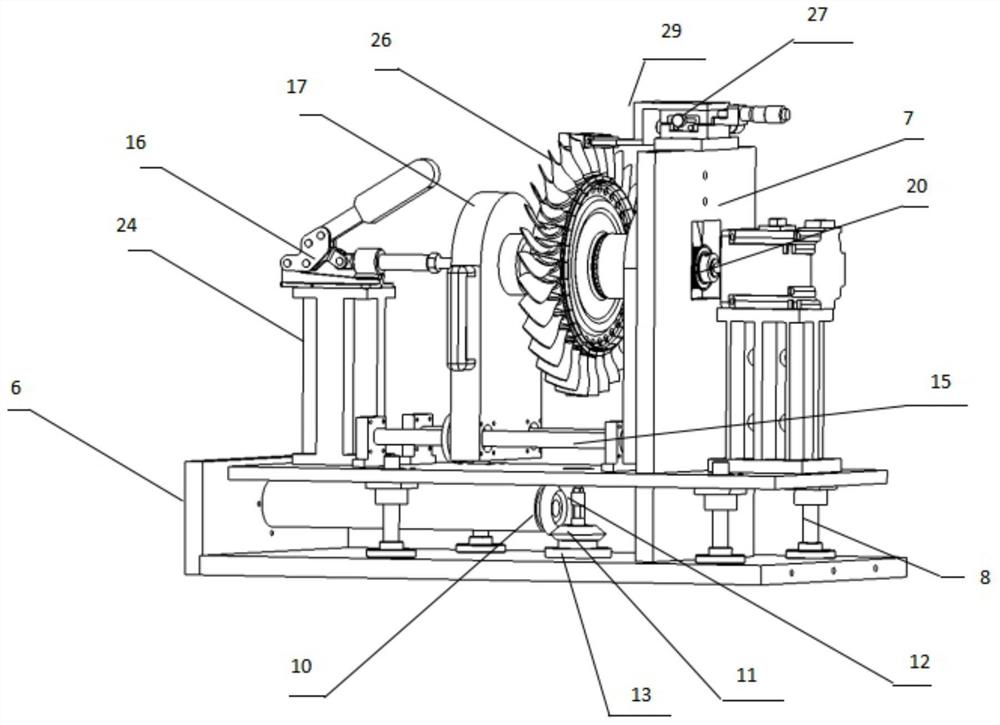

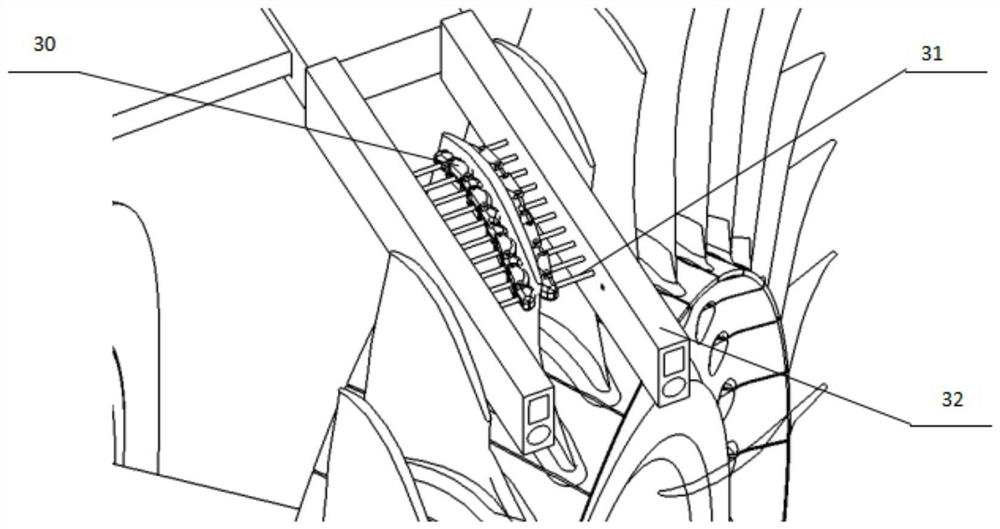

Aero-engine blisk-blade welding repair clamping device

ActiveCN113042956AImprove stabilityDiversified adjustment of clamping process parametersWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention relates to an aero-engine blisk-blade welding repair clamping device which is characterized in that a blisk assembly clamping system is installed on a platform linear lifting system and can ascend and descend along with the platform linear lifting system; and a blade flexible clamping system is located on the top of the platform linear lifting system and can clamp blades of the blisk in the X direction and the Y direction. According to the aero-engine blisk-blade welding repair clamping device provided by the invention, clamping of the blisk is achieved through meshing of end teeth, so that high stability is achieved; blisks with different specifications can be clamped by changing the size of the end teeth, so that diversified adjustment of clamping process parameters is achieved; a single-layer clamping chain is adopted as a clamping tool and a heat dissipation device of the blades, and the position of a clamping block and the clamping pressure of the clamping chain are adjusted by controlling the air supply amount of a clamping air cylinder, so that flexible clamping is achieved, and effective heat dissipation is achieved; and a motor is adopted to drive the end teeth to rotate, and the platform is manually lifted, so that multi-phase adjustment of the blisk and the blades is achieved, the precision of the installation position of the clamping chain clamp is guaranteed, and continuous welding repair between the different blades is achieved.

Owner:杨媛媛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com