An integrated flexible support structure for a rectangular off-axis metal mirror

A metal mirror, flexible support technology, applied in the field of optical remote sensing, can solve the problems of mirror surface deformation, mirror body over-constrained, no translation freedom, etc., to achieve precise installation and positioning, reducing the effect of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further illustrate the present invention below in conjunction with accompanying drawing.

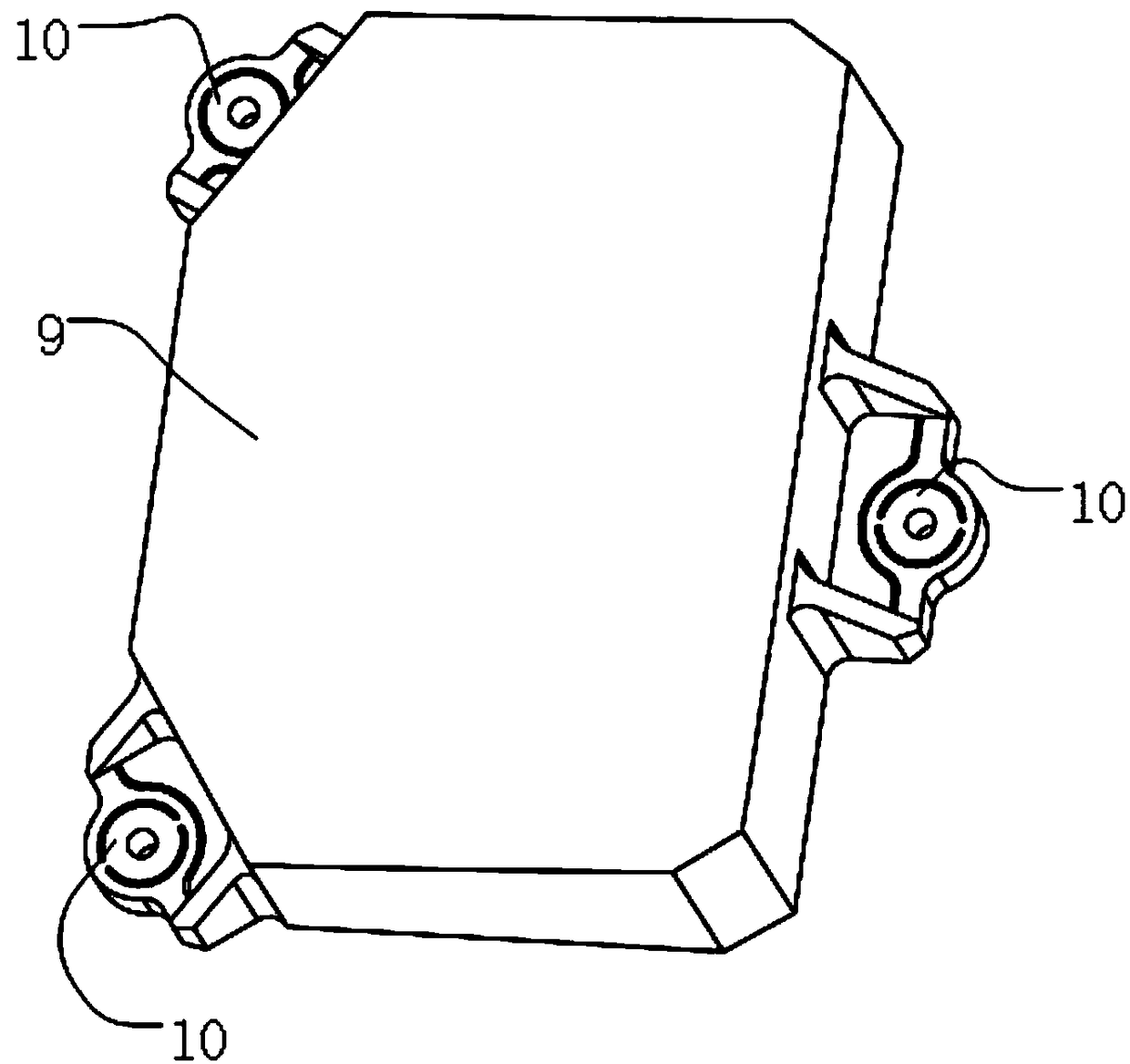

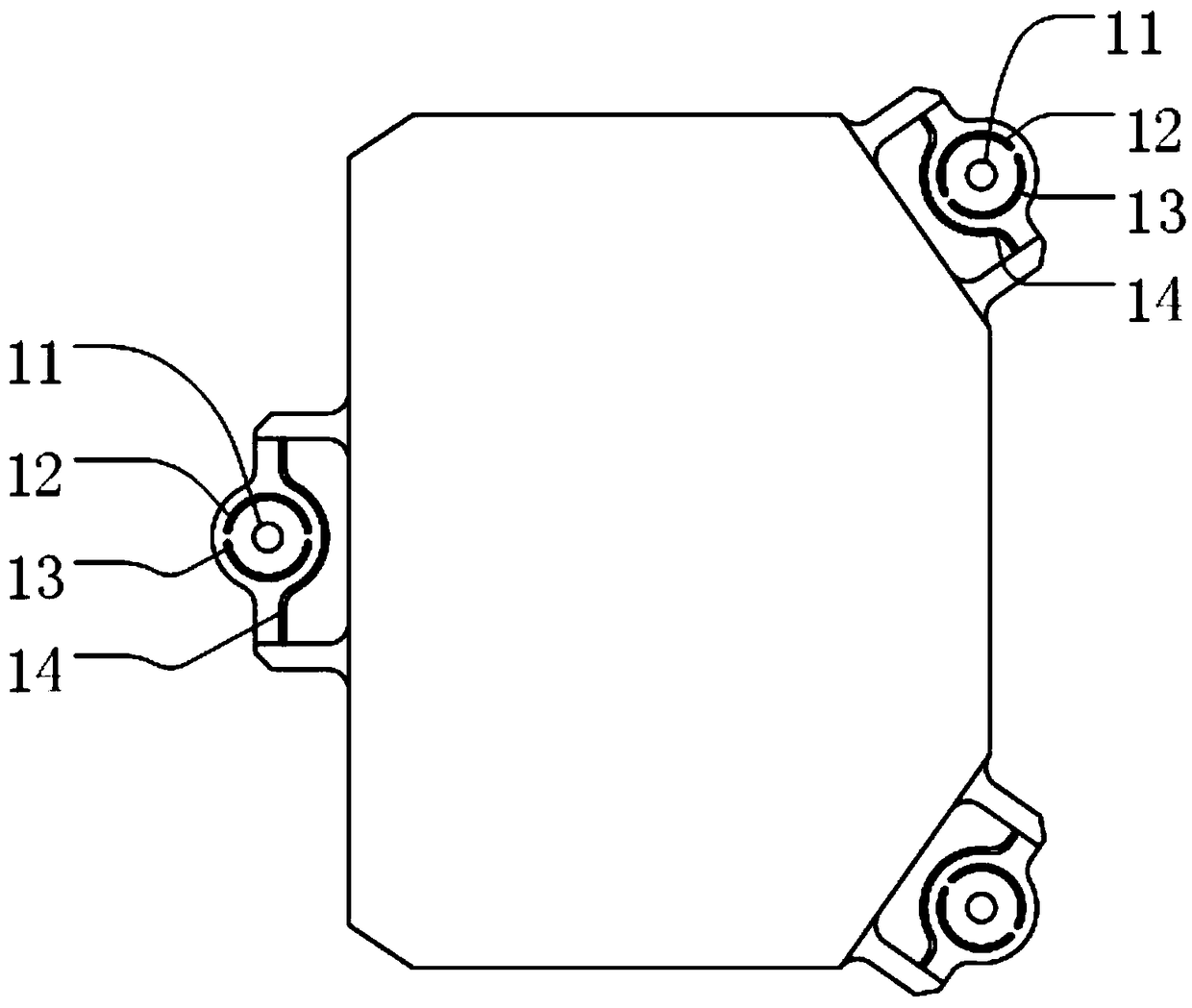

[0024] Such as Figure 2-4 As shown, the integrated flexible support structure of the rectangular metal mirror of the present invention includes a mirror body 9 and three flexible supports 10 .

[0025] Wherein, the mirror body 9 is a rectangular mirror, and the back is milled to obtain lightweight ribs 16 to realize the weight reduction of the metal mirror.

[0026] Three flexible supports 10 are integrally formed with the mirror body 9 and are evenly distributed on the side of the mirror body 9 . Usually, two planes are cut on two adjacent right-angled sides of the mirror body 9, and two flexible supports 10 are respectively fixed, and another flexible support 10 is fixed on a side not connected with the two cutting planes, and the three flexible supports 10 The center points form an equilateral triangle. Each flexible support 10 includes a flexible board and two connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com