Push-pull type printing system and continuous ink-jet printing machine

An inkjet printing machine and printing system technology, applied to typewriters, printing, transfer materials, etc., can solve the problems of inconvenient daily maintenance of the nozzle assembly, the nozzle assembly cannot be pulled out as a whole, and the nozzle assemblies are not parallel to each other, etc., to achieve positioning Good locking effect, fewer parts, and improved printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

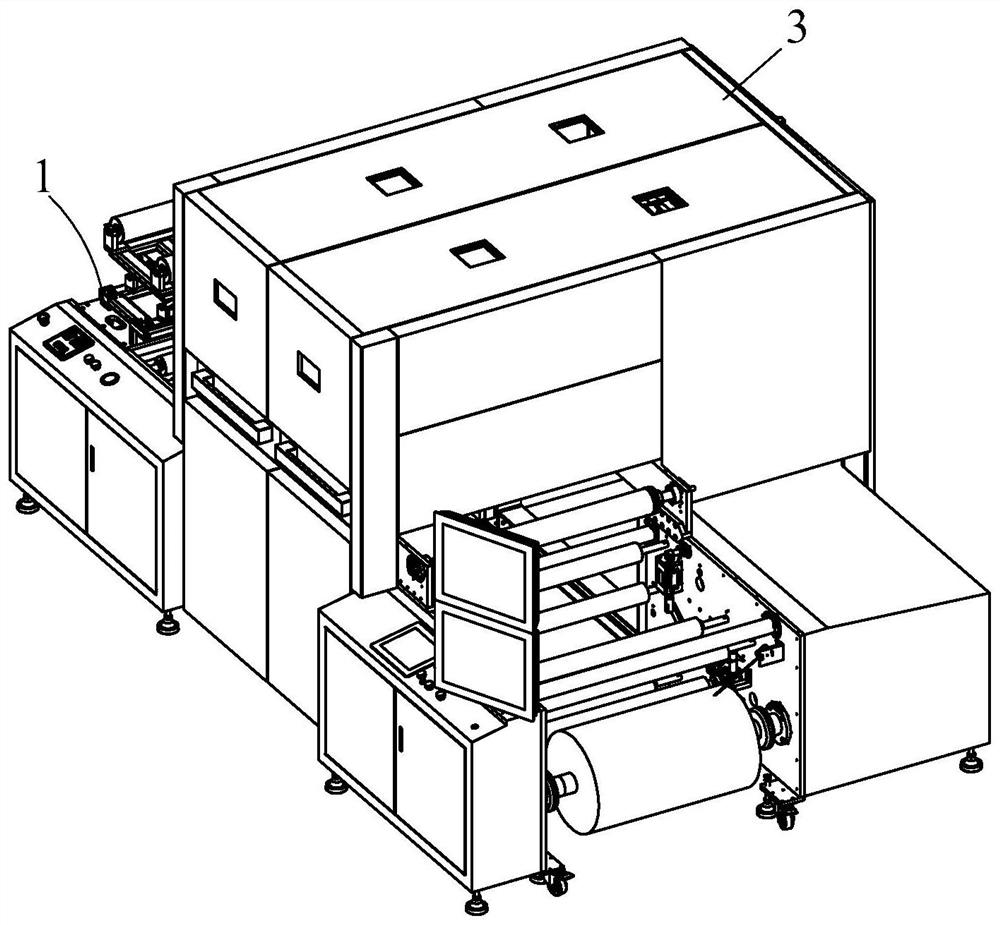

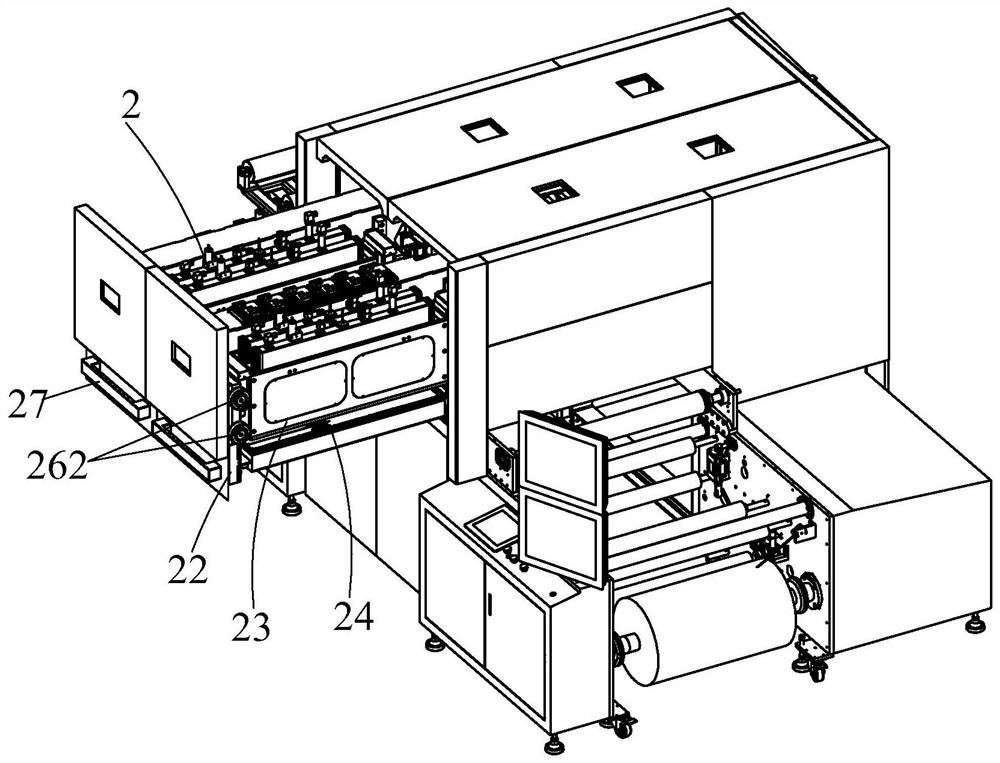

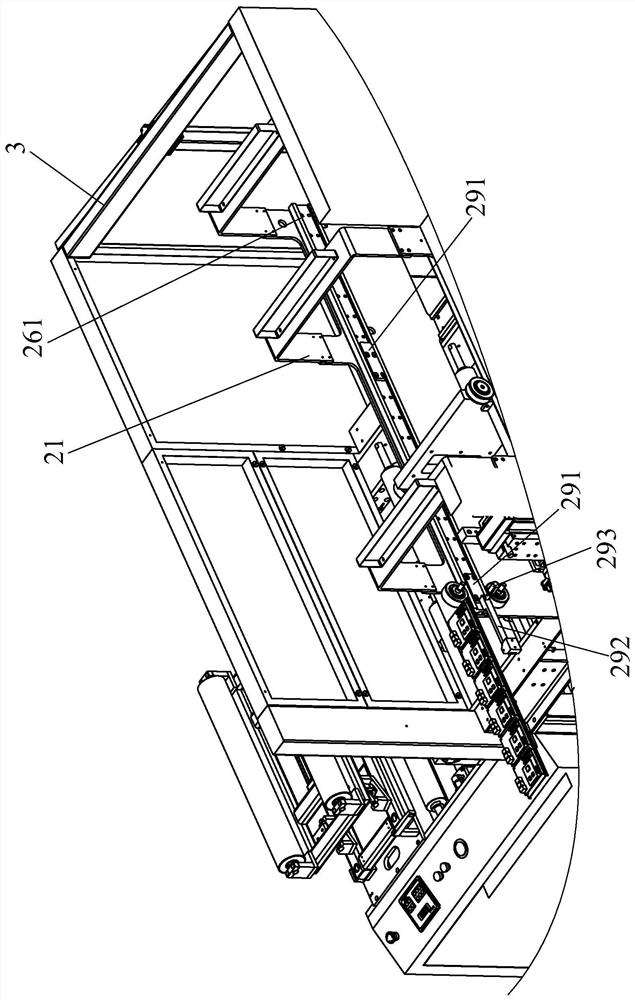

[0062] see Figure 1 to Figure 17 .

[0063] This embodiment discloses a continuous inkjet printing machine, which includes a frame 1, a printing guide belt and a plurality of push-pull printing systems 2, the printing guide belt is installed on the frame 1, and a plurality of push-pull printing systems 2 are arranged side by side Installed on the frame 1 and located above the printing belt, the push-pull printing system 2 can be integrally pulled out along the direction perpendicular to the printing belt movement direction (see figure 2 ) and advance (see figure 1 ), to facilitate the daily maintenance and inspection of the printing system. Multiple push-pull printing systems 2 are covered and protected with a sheet metal shield 3 .

[0064] In this embodiment, the push-pull printing system 2 includes a gantry frame 21 , an outer frame 22 , a nozzle holder 23 , a multidirectional adjustment mechanism for nozzle groups, a push-pull movement mechanism, a locking positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com